A 3D three-dimensional laser anti-counterfeiting label printing device and method

A laser anti-counterfeiting and three-dimensional technology, applied in the direction of identification devices, seals, instruments, etc., can solve the problems of poor anti-counterfeiting effect, poor printing and bonding effect of plane graphic spray printing powder, etc., and achieve good anti-counterfeiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

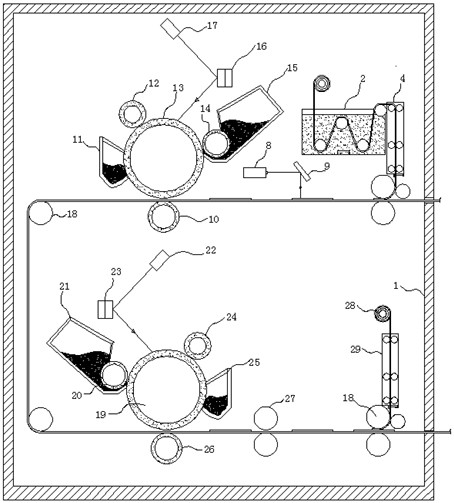

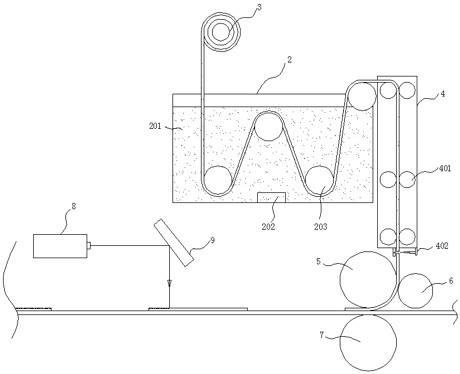

[0043] refer to Figure 1-2 , a 3D three-dimensional laser anti-counterfeit label printing device, including a body 1, also includes

[0044] Ultrasonic cleaning equipment 2, fixedly connected in the body 1;

[0045] The PET film winding shaft 3 is rotatably connected in the body 1;

[0046] The first guiding and separating device 4 is fixedly connected in the body 1;

[0047] The first squeeze wheel 5, the second squeeze wheel 7 and the adhesive coating guide roller 6,

[0048] Wherein, the first squeeze wheel 5 and the second squeeze wheel 7 are arranged symmetrically, and the PET film on the PET film winding shaft 3 passes through the ultrasonic cleaning device 2 and the first guiding and separating device 4 successively, and the first squeeze wheel 5 and the adhesive Adhesive coating guide roller 6 squeezes and guides the PET film;

[0049] The excimer laser 8 and the first mirror 9 are fixedly arranged in the body 1 and irradiate the PET film;

[0050] The first toner ...

Embodiment 2

[0063] refer to Figure 1-2 , a 3D three-dimensional laser anti-counterfeiting label printing device and method, which are basically the same as in Embodiment 1, and furthermore, the ultrasonic cleaning device 2 is filled with cleaning liquid 201, and the ultrasonic cleaning device 2 is rotationally connected with 4 guide rollers 203 , set four guide rollers 203 to adjust the PET cleaning time to the best, and the ultrasonic cleaning equipment 2 is provided with an ultrasonic generator 202 .

Embodiment 3

[0065] refer to Figure 1-2 , a 3D three-dimensional laser anti-counterfeiting label printing device and method, which are basically the same as in Embodiment 1, furthermore, a plurality of symmetrical guide heating rollers 401 are arranged in the first guide and separation device 4, and the first guide and separation device 4 A drying exhaust fan is still arranged in the center, and a film cutting machine 402 is fixedly connected to the lower end of the first guiding and separating device 4; the cleaned PET film is dried and cleaned to facilitate subsequent operations such as gluing and laser.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com