A double solid-color double-needle bed single jacquard spacer fabric and its manufacturing method

A technology for spacer fabrics and production methods, which is applied in knitting, warp knitting, textiles, and papermaking, and can solve the problems of limited pattern designs and inability to meet the needs of production updates, achieving rich effects, simple design, and increased operability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

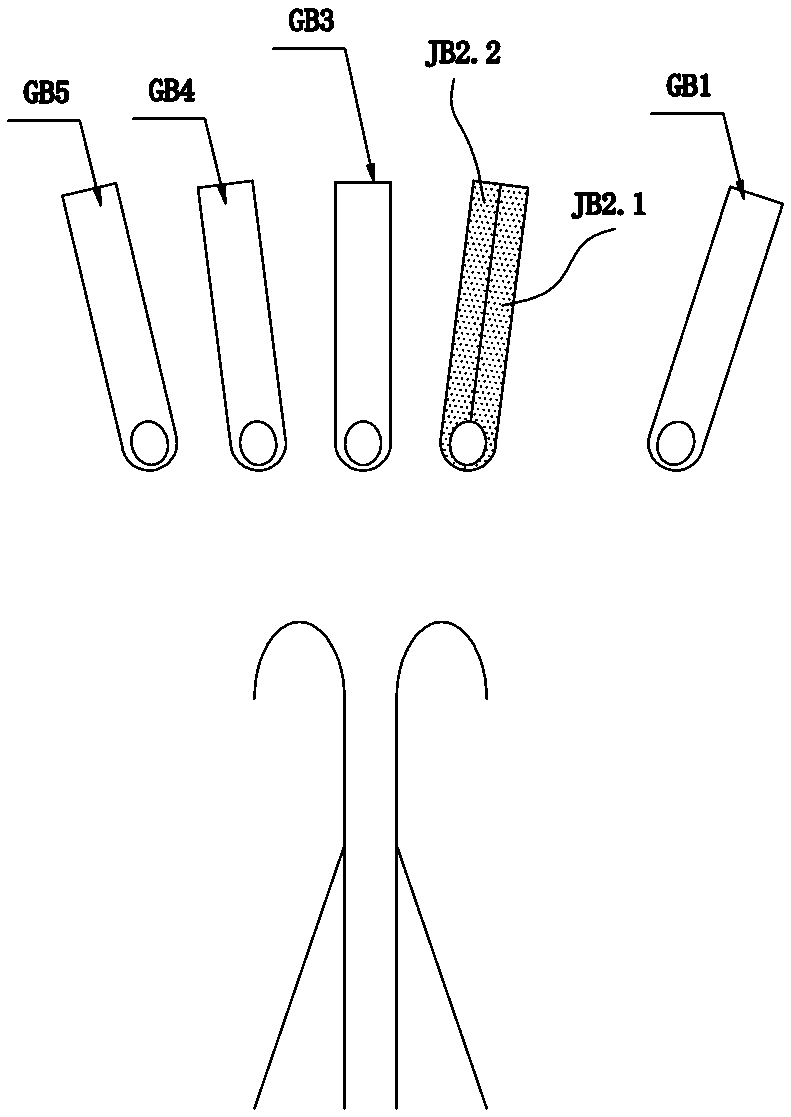

[0022] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0023] refer to figure 1 . The present invention is produced on the conventional RDJ5 / 1 model, and the machine is configured as follows from machine to machine: ground comb GB1, two and a half machine number jacquard combs JB2.1 and JB2.2, ground comb GB3, and ground comb GB4 , Ground comb GB5, wherein, the ground comb GB1 only acts on the front needle bed, two half gauge jacquard combs JB2.1 and JB2.2 are arranged oppositely, and acts on the front and rear needle beds, and the ground comb GB3 acts on the front and rear needle beds , GB4 and GB5 only act on the rear needle bed.

[0024] The ground comb GB1 is covered with 75D polyester semi-gloss filaments, and the braided chain structure is 1-0-1-1 / 0-1-1-1 / / .

[0025] Half gauge jacquard comb JB2.1 is fully worn with 150D polyester low elastic yarn, the basic traverse data is 1-0-1-0 / 2-3-2-3 / /

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com