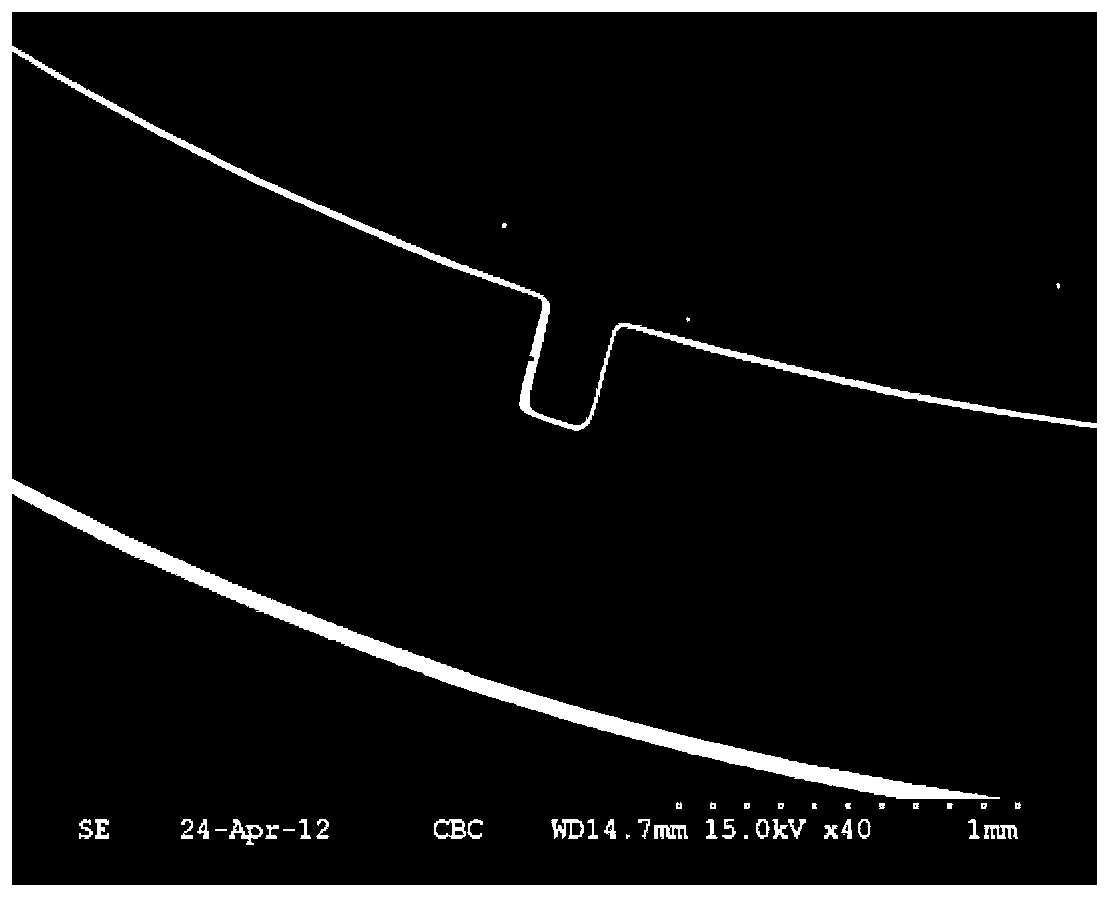

Passive spiral micro-structural mixing unit and application thereof

一种混合装置、微结构的技术,应用在混合机、流态混合器、运输和包装等方向,能够解决不利混合、会贴壁流动等问题,达到优化混合效果、广阔应用前景的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0026] In Examples 1-6, the Villermaux-Dushman rapid parallel competitive reaction was used as a model system to investigate the difference in the micro-mixing effect of micro-mixing devices with different sampling angles. The concentration of each substance in the model system is: Liquid A: KI 1.16×10 -3 mol / L, KIO 3 2.23×10 -3 mol / L,H 3 BO 3 1.818×10 -2 mol / L, liquid B: NaOH 9.09×10 -2 mol / L,H 2 SO 4 0.024mol / L; the flow rate of the two liquid phases is 0.27mL / min, using a UV spectrophotometer Concentration is measured, and then the separation factor is calculated, and the results are published in Table 1:

[0027] Table 1

[0028]

Embodiment 7

[0034] At room temperature, 2.5mol / L Na 2 SO 4 with BaCl 2The solution was injected into the spiral microstructure mixing device with vertical baffles through two inlet pipes at an equal flow rate of 5mL / min for mixing. The samples collected at the outlet of the device were washed with ethanol solution and placed in an oven at 100°C. dried for 24 hours to obtain d 43 100 nm barium sulfate particles.

Embodiment 8

[0036] At room temperature, 1mol / L Na 2 SO 4 with BaCl 2 The solution was injected into the spiral microstructure mixing device with vertical baffles from two inlet pipes at an equal flow rate of 1 mL / min for mixing. The samples collected at the outlet of the device were washed with ethanol solution and placed in an oven at 100 °C. dried for 24 hours to obtain d 43 500 nm barium sulfate particles.

[0037] It can be shown from the above examples and comparative examples that the spiral micro-mixing device proposed by the present invention has a higher micro-mixing effect compared with the prior art, and it has a better synthesis effect in the synthesis of barium sulfate nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com