Method for preparing negative electrode material for sodium-ion battery from KOH activated pomelo peel

A technology for sodium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high energy consumption, difficult control, and long reaction cycle in the reaction process, and achieve high capacity, improve efficiency, and reaction time. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

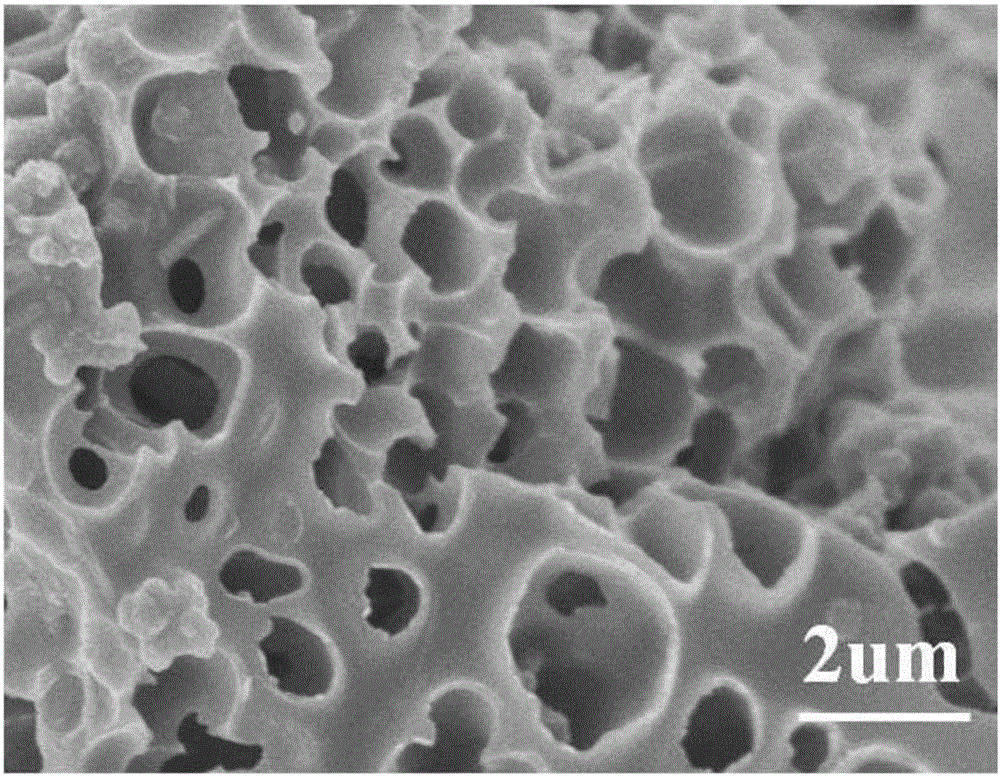

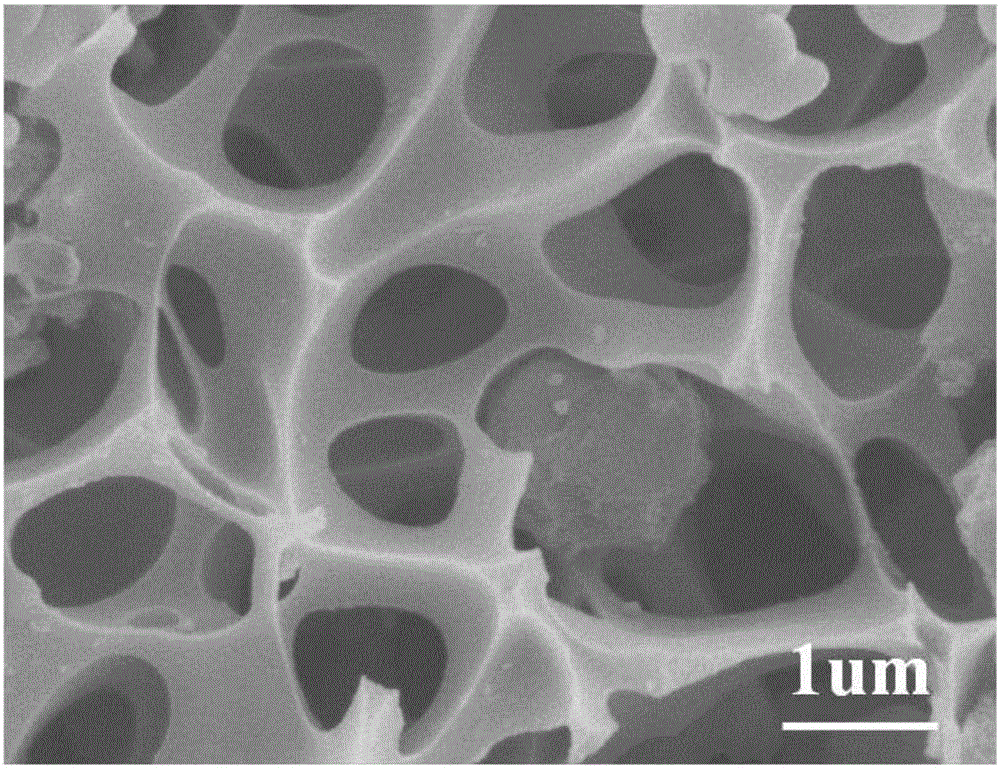

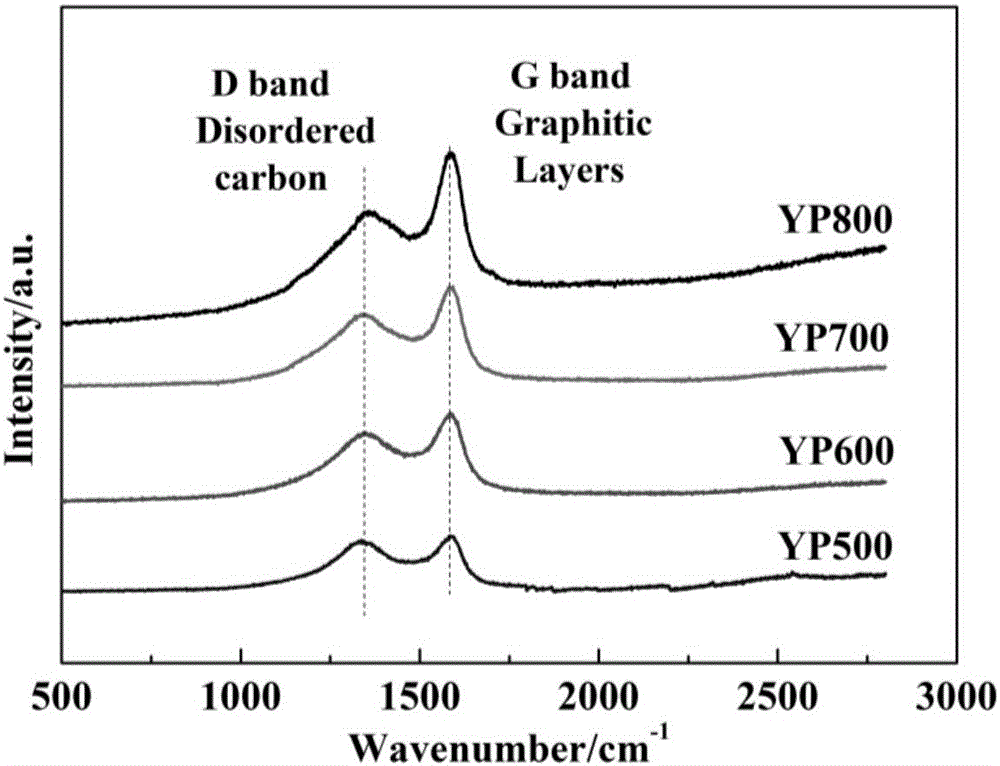

Method used

Image

Examples

Embodiment 1

[0039] (1) Wash the pomelo peel of the biomass prefabricated body to remove surface impurities, and shred it to obtain a uniform block A with a diameter of 5 mm;

[0040] (2) Freeze-dry the uniform block A at 0°C for 36 hours to obtain block B;

[0041] (3) Take 0.5g of block B, add solid superacid to block B according to the mass ratio of B: solid superacid of 3:1, then add 40ml of ethanol solution, and magnetically stir for 1.5h to form a mixed solution C;

[0042] (4) Transfer the mixed solution C to a homogeneous hydrothermal reaction kettle, seal it and put it into a homogeneous reactor, heat up to 180°C at a heating rate of 15°C / min for hydrothermal reaction for 24 hours, then cool naturally to room temperature to obtain water Thermal product D, wherein the lining of the reactor is polytetrafluoroethylene, and the filling ratio of the reactor is 40%;

[0043] (5) After the precursor D was washed and filtered, the precursor D:KOH solid was mixed according to the mass rat...

Embodiment 2

[0047] (1) Wash the pomelo peel of the biomass prefabricated body to remove surface impurities, and shred it to obtain a uniform block A with a diameter of 3 mm;

[0048] (2) Freeze-dry the uniform block A at -20°C for 12 hours to obtain block B;

[0049] (3) Take 1g of block B, add solid superacid to block B according to the mass ratio of B: solid superacid of 2:1, then add 50ml of ethanol solution, and magnetically stir for 0.5h to form a mixed solution C;

[0050] (4) Transfer the mixed liquid C to a homogeneous hydrothermal reaction kettle, seal it and put it into a homogeneous reactor, heat up to 150°C at a heating rate of 15°C / min for hydrothermal reaction for 12 hours, then cool naturally to room temperature to obtain water Thermal product D, wherein the lining of the reactor is polytetrafluoroethylene, and the filling ratio of the reactor is 50%;

[0051] (5) After the precursor D was washed and filtered, the precursor D:KOH solid was mixed according to the mass ratio...

Embodiment 3

[0054] (1) Wash the pomelo peel of the biomass prefabricated body to remove surface impurities, and shred it to obtain a uniform block A with a diameter of 3 mm;

[0055] (2) Freeze-drying uniform block A at 0°C for 24 hours to obtain block B;

[0056] (3) Take 1.5g of block B, add solid superacid to block B according to the mass ratio of B: solid superacid of 1:1, then add 60ml of ethanol solution, and magnetically stir for 1h to form a mixed solution C;

[0057] (4) Transfer the mixed solution C to a homogeneous hydrothermal reaction kettle, seal it and put it into a homogeneous reactor, heat up to 160°C at a heating rate of 15°C / min for hydrothermal reaction for 24 hours, then cool naturally to room temperature to obtain water Thermal product D, wherein the lining of the reactor is polytetrafluoroethylene, and the filling ratio of the reactor is 60%;

[0058] (5) After the precursor D was washed and filtered, the precursor D:KOH solid was mixed uniformly at a mass ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com