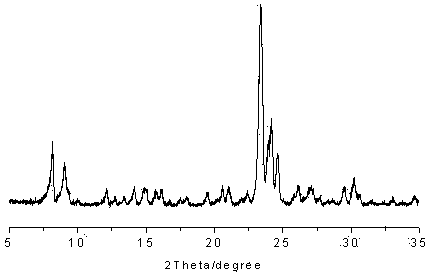

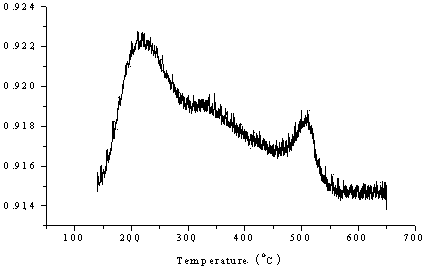

ZSM-5 molecular sieve and preparation method thereof

A ZSM-5, molecular sieve technology, applied in the directions of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of high preparation cost, pollute the environment, limit shape selection performance, etc., and achieve synthesis low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In the first step, add sodium hydroxide and aluminum sulfate into deionized water respectively, stir for half an hour, add silica sol, stir evenly, put it into a stainless steel crystallization kettle, crystallize at a constant temperature of 170°C for 60 hours, and then cool to room temperature .

[0021] The second step is to stir the cooled mixture after crystallization. After stirring evenly, add aluminum sulfate directly, then stir for 2 hours, put it into a stainless steel crystallization kettle, and crystallize at a constant temperature of 178°C for 48 hours, then cool to room temperature, and wash , drying and roasting to obtain ZSM-5 molecular sieve.

[0022] The molar ratio of synthetic raw materials is (excluding the aluminum source added in the second step): Al 2 o 3 :60SiO2 2 :9.4Na 2 O:3778H 2 O. The aluminum source that the second step adds is the 62% of the first step (mass percentage, with Al 2 o 3 count).

Embodiment 2

[0027] In the first step, add sodium hydroxide and aluminum sulfate into deionized water respectively, stir for half an hour, add silica sol, stir evenly, put it into a stainless steel crystallization kettle, crystallize at a constant temperature of 170°C for 72 hours, and then cool to room temperature .

[0028] The second step is to stir the cooled mixture after crystallization. After stirring evenly, add aluminum nitrate directly, then stir for 2 hours, put it into a stainless steel crystallization kettle, and crystallize at a constant temperature of 175°C for 36 hours, then cool to room temperature, and wash , drying and roasting to obtain ZSM-5 molecular sieve.

[0029] The molar ratio of synthetic raw materials is (excluding the aluminum source added in the second step): Al 2 o 3 :60SiO2 2 :9.4Na 2 O:3778H 2 O. The aluminum source that the second step adds is 60% of the first step (mass percentage, with Al 2 o 3 count).

Embodiment 3

[0031] In the first step, add sodium hydroxide and aluminum sulfate into deionized water respectively, stir for half an hour, add silica sol, stir evenly, put it into a stainless steel crystallization kettle, crystallize at a constant temperature of 170°C for 60 hours, and then cool to room temperature .

[0032] The second step is to stir the cooled mixture after crystallization. After stirring evenly, add aluminum sulfate directly, then stir for 2 hours, put it into a stainless steel crystallization kettle, crystallize at a constant temperature of 170°C for 60 hours, then cool to room temperature, and wash , drying and roasting to obtain ZSM-5 molecular sieve.

[0033] The molar ratio of synthetic raw materials is (excluding the aluminum source added in the second step): Al 2 o 3 :90SiO2 2 :9.4Na 2 O:3780H 2 O. The aluminum source that the second step adds is the 77% of the first step (mass percentage, with Al 2 o 3 count).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com