Novel method for preparing 1,1,1,3,5,5,5-heptamethyltrisiloxane by adopting solid superacid

A technology of heptamethyltrisiloxane and solid superacid, which is applied in chemical instruments and methods, silicon organic compounds, physical/chemical process catalysts, etc., can solve the problem of no fixed mode, etc., and achieve easy separation and low production cost , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

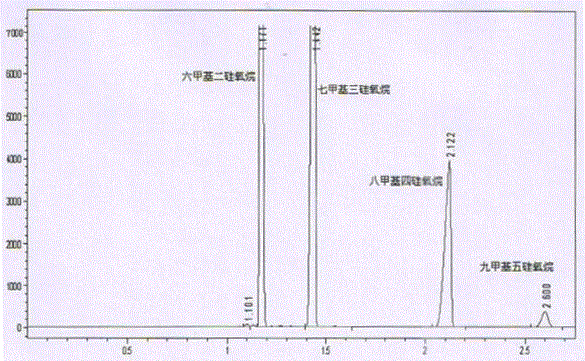

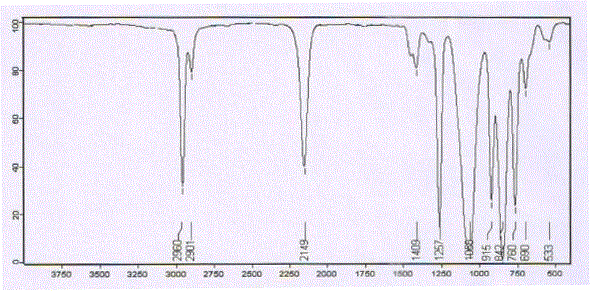

Image

Examples

Embodiment 1

[0030] The preparation method of 1,1,1,3,5,5,5-heptamethyltrisiloxane comprises the following steps: mixing 202 hydrogen-containing silicone oil, hexamethyldisiloxane, and solid superacid catalyst in a mass ratio of 6.2 :1:0.27 is placed in a reactor with mechanical stirring, thermometer and reflux condenser, the temperature is raised under stirring, the temperature is controlled at 70°C for 7 hours, and it is left to stand for 2 hours, and the supernatant is filtered to obtain the filtrate, which is used Distillation in the rectification tower to obtain 1,1,1,3,5,5,5-heptamethyltrisiloxane product;

[0031] The solid superacid catalyst of the present invention is SO 4 2- / ZrO 2 -Fe 2 o 3 -Sm 2 o 3 , SO 4 2- / TiO 2 , SO 4 2- / ZrO 2 -Ce 2 (SO 4 ) 3 ; And the mass ratio of each catalyst is 2:3:1.6;

[0032] The preparation method of solid superacid catalyst is as follows:

[0033] SO 4 2- / TiO 2 Preparation of solid superacid catalyst: under constant stirring...

Embodiment 2

[0038] The preparation method of 1,1,1,3,5,5,5-heptamethyltrisiloxane of the present invention comprises the following steps: 202 hydrogen-containing silicone oil, hexamethyldisiloxane, solid superacid catalyst by mass The ratio of 3:1:0.08 is placed in a reactor equipped with mechanical stirring, a thermometer and a reflux condenser, the temperature is raised under stirring, the temperature is controlled at 50°C for 5 hours, and it is left to stand for 1 hour. The supernatant is filtered to obtain the filtrate, and the The filtrate is rectified by a rectification tower to obtain 1,1,1,3,5,5,5-heptamethyltrisiloxane product;

[0039] The solid superacid catalyst of the present invention is SO 4 2- / TiO 2 ;

[0040] The preparation method of solid superacid catalyst is as follows:

[0041] SO 4 2- / TiO 2 Preparation of solid superacid catalyst: under constant stirring, TiCl 4Add it to ammonia water with a mass fraction of 20%, adjust the pH value to 9, hydrolyze, let it...

Embodiment 3

[0044] The preparation method of 1,1,1,3,5,5,5-heptamethyltrisiloxane of the present invention comprises the following steps: 202 hydrogen-containing silicone oil, hexamethyldisiloxane, solid superacid catalyst by mass The ratio 10:1:0.66 is placed in a reactor with mechanical stirring, a thermometer and a reflux condenser, the temperature is raised under stirring, the temperature is controlled at 90°C for 9 hours, and the reaction is allowed to stand for 3 hours. The supernatant is filtered to obtain the filtrate, and the The filtrate is rectified by a rectification tower to obtain 1,1,1,3,5,5,5-heptamethyltrisiloxane product;

[0045] The solid superacid catalyst of the present invention is SO 4 2- / ZrO 2 ;

[0046] The preparation method of solid superacid catalyst is as follows:

[0047] SO 4 2- / ZrO 2 Preparation of solid superacid catalyst: under constant stirring, ZrCl 4 Add it to ammonia water with a mass fraction of 24%, adjust the pH value to 9, hydrolyze, le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com