Preparation method of biodegradable lubricating oil

A technology of lubricating oil and epoxy biodiesel, applied in lubricating compositions, petroleum industry, base materials, etc., can solve problems such as high reaction temperature, affecting reaction balance, and decreased catalyst activity, so as to reduce reaction temperature and reaction time , the effect of reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

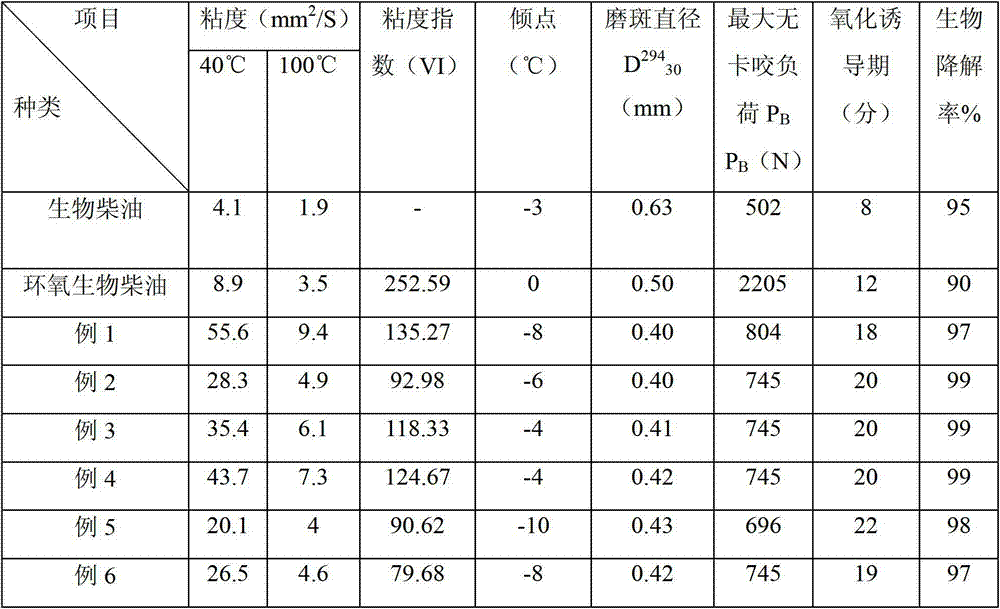

Examples

Embodiment 1

[0026] Weigh acetic acid and SO 4 2- / ZrO 2 The catalyst is placed in a three-necked flask with a condenser and a stirrer, stirred in an ultrasonic (ultrasonic frequency is 40KHz, ultrasonic power is 800W) water bath device, reflux, heated to a temperature of 60 ° C, and then adding epoxy biodiesel (ring Oxygenated soybean oil fatty acid methyl ester), the molar ratio of epoxy soybean oil fatty acid methyl ester and acetic acid is 1:2, the mass ratio of catalyst and epoxy soybean oil fatty acid methyl ester is 2.5:100, ring-opening reaction, during the reaction , take a sample every 15 minutes, take a sample from a three-necked flask, and measure the epoxy value of the sample after alkali washing and decompression to recover the fatty acid. After 1 hour, the epoxy value tends to 0 and does not change anymore, which is end point of the reaction. When the reaction reaches the end, the reaction is stopped, the reaction mixture is cooled to room temperature, poured into a separ...

Embodiment 2

[0031] Weigh out butyric acid and SO 4 2- / Fe 2 o 3 The catalyst is placed in a three-necked flask with a condenser and a stirrer, stirred in an ultrasonic (ultrasonic frequency is 28KHz, ultrasonic power is 700W) water bath device, reflux, heated to a temperature of 55 ° C, and then adding epoxy biodiesel (ring Oxygenated rapeseed oil fatty acid methyl ester), the molar ratio of epoxy rapeseed oil fatty acid methyl ester and butyric acid is 1:4, the mass ratio of catalyst and epoxy rapeseed oil fatty acid methyl ester is 2.5:100, ring-opening reaction , take a sample every 15 minutes in the reaction process, take a sample from a three-necked flask, measure its epoxy value (the assay method of epoxy value, as described in Example 1) after the sample is washed with alkali and reclaim the fatty acid under reduced pressure, After 1h, the epoxy value tends to 0 and does not change, which is the end of the reaction. When the reaction reaches the end, the reaction is stopped, th...

Embodiment 3

[0033] Weigh valeric acid and SO 4 2- / Al 2 o 3 The catalyst is placed in a three-necked flask with a condenser and a stirrer, stirred in an ultrasonic (ultrasonic frequency is 45KHz, and ultrasonic power is 450W) water bath device, refluxed, heated to a temperature of 55 ° C, and then added epoxy biodiesel (ring Oxygenated castor oil fatty acid methyl ester), the molar ratio of epoxy castor oil fatty acid methyl ester and valeric acid is 1:5, the mass ratio of catalyst to epoxy castor oil fatty acid methyl ester is 3:100, ring-opening reaction, reaction process Sampling every 15 minutes, sampling from the three-necked flask, after the sample was washed with alkali and reclaiming the fatty acid under reduced pressure, measure its epoxy value (the assay method of epoxy value, as described in Example 1), after 1.5 h, the epoxy value tends to 0, and no longer changes, which is the end of the reaction. When the reaction reaches the end, the reaction is stopped, the reaction mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com