Water-based shoe lining leather bass and preparation method thereof

A leather bass and water-based technology, applied in the field of leather bass for water-based shoes and its preparation, can solve the problems of large environmental impact, unenvironmental protection, poor moisture permeability and air permeability, etc., and achieves good air permeability, good elasticity recovery, The effect of improving strength and water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

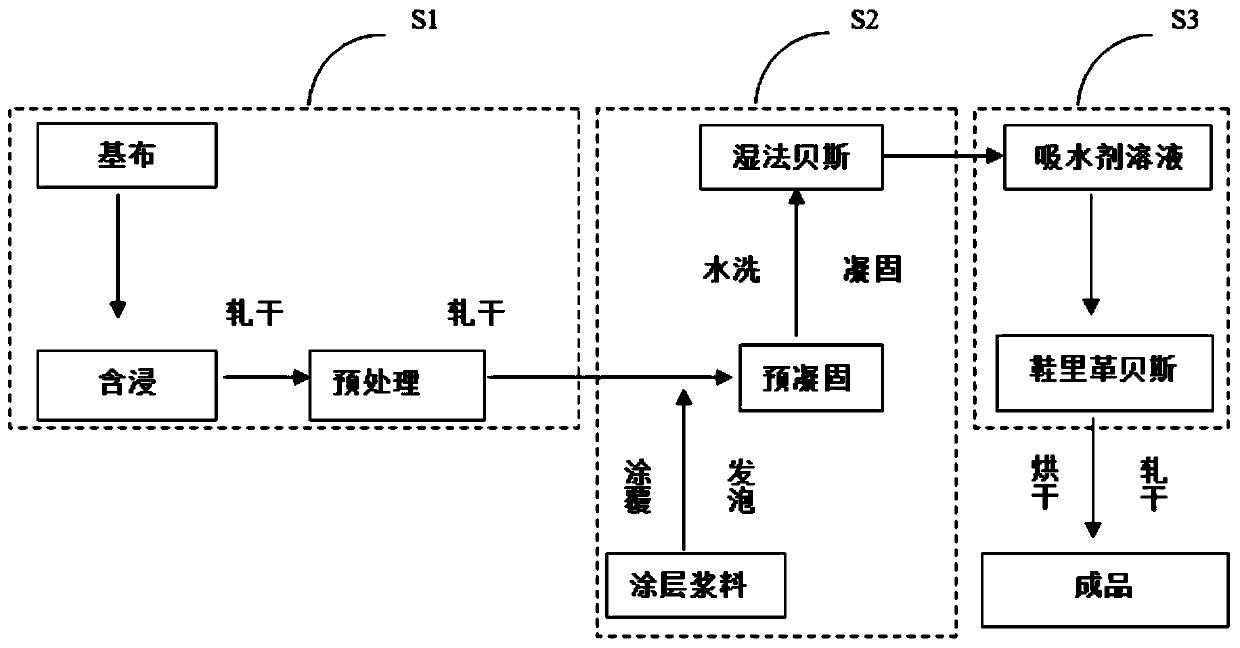

Method used

Image

Examples

Embodiment 1

[0059] (1) Configuration of impregnation materials

[0060] Take 20 parts of water-based polyurethane (model: 702c) and 100 parts of water and add them to the mixer for stirring. While stirring, gradually add 0.6 parts of water-based defoamer (model: XP05), 0.7 parts of pH regulator (model: ZQ03), water-based Thickener (model: ZQ05) 2 parts, stir until the slurry is evenly dispersed, adjust the viscosity to 2000-2500cps.

[0061] (2) Configuration of coating slurry

[0062] Get 200 parts of water-based polyurethane (model: 702e), 4 parts of water-based dispersant (model: FS05), 30 parts of 500 mesh wood flour (model: F17), 20 parts of 8000 mesh kaolin (model: TC02), blowing agent (model : ZQ17) 15 parts, foam stabilizer (model: ZQ12) 15 parts, water-absorbing agent (model: ZQ65) 10 parts, water-based thickener (model: ZC05) 3 parts in a mixer and mix evenly until the viscosity is 15000cps, The prepared slurry is mechanically foamed through a foaming machine, with a foaming r...

Embodiment 2

[0069] (1) Configuration of impregnation materials

[0070] Take 20 parts of water-based polyurethane (model: 702c) and 100 parts of water and add them to the mixer for stirring. While stirring, gradually add 0.3 parts of water-based defoamer (model: XP05), 0.4 parts of pH regulator (model: ZQ03), water-based Thickener (model: ZQ05) 1 part, stir until the slurry is evenly dispersed, and adjust the viscosity to 2000-2500cps.

[0071] (2) Configuration of coating slurry

[0072] Get 200 parts of water-based polyurethane (model: 702e), 2 parts of water-based dispersant (model: FS05), 20 parts of 500 mesh wood flour (model: F17), 10 parts of 8000 mesh kaolin (model: TC02), foaming agent (model : 10 parts of ZQ17), 10 parts of foam stabilizer (model: ZQ12), 8 parts of water-absorbing agent (model: ZQ65), 1 part of water-based thickener (model: ZC05) and mix them evenly in a mixer until the viscosity is 15000cps. The prepared slurry is mechanically foamed through a foaming machine...

Embodiment 3

[0079] (1) Configuration of impregnation materials

[0080] Take 20 parts of water-based polyurethane (model: 702c) and 100 parts of water and add them to the mixer for stirring. While stirring, gradually add 0.4 parts of water-based defoamer (model: XP05), 0.5 parts of pH regulator (model: ZQ03), water-based Thickener (model: ZQ05) 2 parts, stir until the slurry is evenly dispersed, adjust the viscosity to 2000-2500cps.

[0081] (2) Configuration of coating slurry

[0082] Get 200 parts of water-based polyurethane (model: 702e), 3 parts of water-based dispersant (model: FS05), 25 parts of 500 mesh wood flour (model: F17), 10 parts of 8000 mesh kaolin (model: TC02), foaming agent (model : 12 parts of ZQ17), 12 parts of foam stabilizer (model: ZQ12), 10 parts of water-absorbing agent (model: ZQ65), 2 parts of water-based thickener (model: ZC05) and mix them evenly in a mixer until the viscosity is 15000cps. The prepared slurry is mechanically foamed by a foaming machine, with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com