Ceramsite soilless culture substrate as well as preparation method and application thereof

A soilless culture substrate, ceramsite technology, applied in planting substrates, botanical equipment and methods, applications, etc., can solve the problems of unbalanced soil microbial population structure, high technical difficulty, poor continuous cropping efficiency, etc., to prevent rapid pH value. Effect of variation, rough and hard surface, good physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

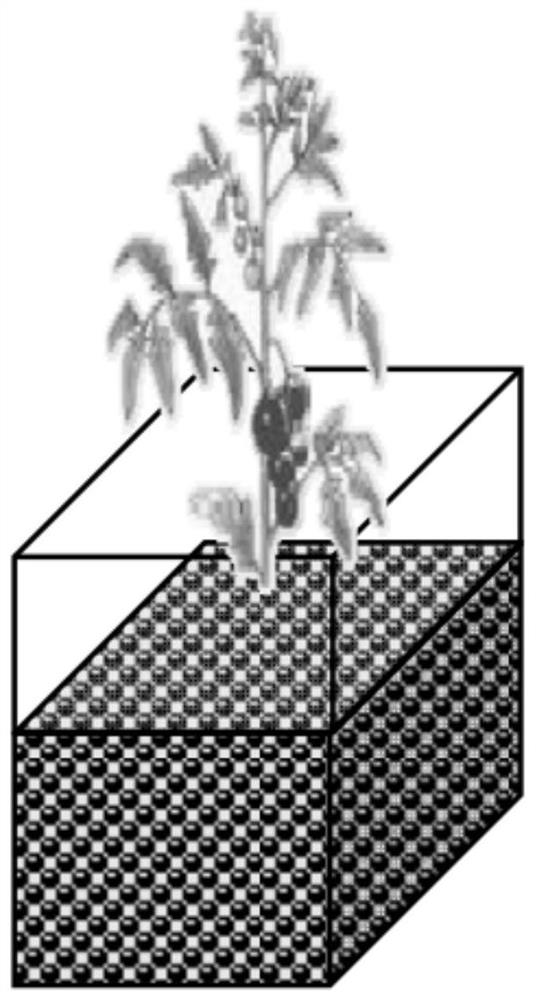

Image

Examples

Embodiment 1

[0030] A preparation method of ceramsite soilless culture substrate, comprising the following steps:

[0031] Step 1. Rinse the shells, dry them under natural conditions, and then put them in a traditional Chinese medicine grinder to crush them for 5 minutes, crush them three times, pass them through a 150-mesh sieve, then calcinate them at 1000°C for 2 hours, and cool them naturally to get the shells calcined powder;

[0032] Step 2. Prepare the calcined shell powder with 0.85% NaCl physiological saline to make a suspension of 1 wt.% for later use, then add fly ash ceramsite and stir evenly to obtain a mixture A, wherein the calcined shell powder and fly ash The mass ratio of ceramsite is 1:20;

[0033] Step 3. Use 20 wt.% gelatin as the water phase, heat it in a water bath at 55°C, then use 0.05 g / mL liquid paraffin solution as the oil phase, and then add the preheated gelatin solution dropwise to the oil phase, stirring while adding , emulsified for 10 min after dropwise ...

Embodiment 2

[0038] A preparation method of ceramsite soilless culture substrate, comprising the following steps:

[0039] Step 1. Rinse the shells, dry them under natural conditions, and then put them in a traditional Chinese medicine grinder to crush them for 5 minutes, crush them three times, pass them through a 150-mesh sieve, then calcinate them at 1000°C for 2 hours, and cool them naturally to get the shells calcined powder;

[0040] Step 2. Prepare the calcined shell powder with 0.85% NaCl physiological saline to make a suspension of 4 wt.% for later use, then add fly ash ceramsite and stir well to obtain mixture A, wherein the calcined shell powder and fly ash The mass ratio of ceramsite is 1: 30;

[0041] Step 3. Use 20 wt.% gelatin as the water phase, heat it in a water bath at 65°C, then use 0.05 g / mL liquid paraffin solution as the oil phase, then add the preheated gelatin solution drop by drop into the oil phase, and stir while adding , emulsified for 10 min after dropwise a...

Embodiment 3

[0046] A preparation method of ceramsite soilless culture substrate, comprising the following steps:

[0047] Step 1. Rinse the shells, dry them under natural conditions, and then put them in a traditional Chinese medicine grinder to crush them for 5 minutes, crush them three times, pass them through a 150-mesh sieve, then calcinate them at 1000°C for 2 hours, and cool them naturally to get the shells calcined powder;

[0048] Step 2. Prepare the shell calcined powder with 0.85% NaCl physiological saline to make a 2 wt.% suspension for later use, then add fly ash ceramsite and stir well to obtain mixture A, wherein, shell calcined powder and fly ash The mass ratio of ceramsite is 1:25;

[0049]Step 3. Use 20 wt.% gelatin as the water phase, heat it in a water bath at 62°C, then use 0.05 g / mL liquid paraffin solution as the oil phase, then add the preheated gelatin solution dropwise to the oil phase, and stir while adding , emulsified for 10 min after dropwise addition, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com