Composite elastic melt-blown non-woven fabric and processing method thereof

A processing method and technology of non-woven fabrics, applied in chemical instruments and methods, non-woven fabrics, textiles and papermaking, etc., can solve problems such as poor water absorption, improve water absorption performance, good waterproof and air permeability, and broaden the application field Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

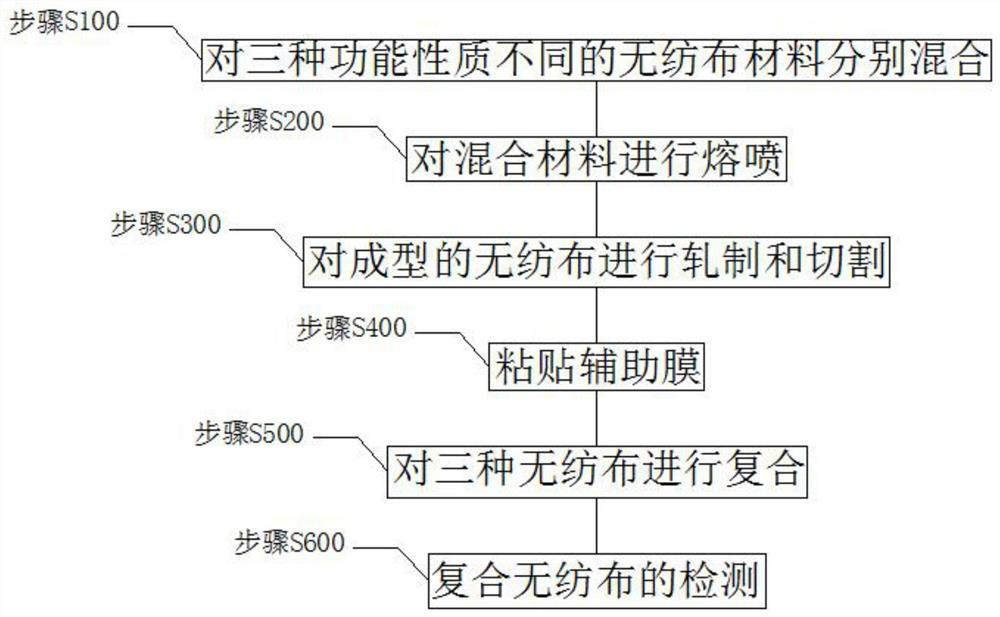

Method used

Image

Examples

Embodiment 1

[0026] External non-woven fabric, including the following percentages by mass: high-fat polypropylene 70%, low-fat polypropylene 10%, emulsifier 0.6%, wetting agent 0.3%, wetting agent 0.3%, spreading agent 0.3%, antistatic agent 1%, graphene 0.4%, color masterbatch 1%, and the balance is distilled water.

[0027] In this embodiment, first, high-fat polypropylene, low-fat polypropylene and color masterbatch are hot-melt mixed, and then emulsifier, wetting agent, wetting agent, spreading agent, antistatic agent and graphene are added to the mixed melt Liquid, the main component of the external non-woven fabric is high-fat polypropylene, which is used to ensure the elasticity and waterproof ability of the composite non-woven fabric. By adding a certain proportion of graphene, the waterproof performance of the non-woven fabric is effectively improved, and then melted The liquid is sprayed onto the roller for hot-melt molding. The hot-melt formed non-woven fabric has a large area ...

Embodiment 2

[0029] The middle non-woven fabric, including the following percentages by mass: high-fat polypropylene 30%, low-fat polypropylene 50%, emulsifier 0.6%, wetting agent 0.3%, wetting agent 0.3%, spreading agent 0.3%, antistatic Agent 1%, polyether silicone oil 0.2%, color masterbatch 1%, the balance is distilled water.

[0030] In this embodiment, first, high-fat polypropylene, low-fat polypropylene and color masterbatch are hot-melt mixed, and then emulsifier, wetting agent, wetting agent, spreading agent, antistatic agent and polyether silicone oil are added and mixed Melt, the main components of the middle non-woven fabric are high-fat polypropylene and low-fat polypropylene, which makes the formed middle non-woven fabric have larger pores and improves the water absorption and air permeability of the middle non-woven fabric. By adding a certain proportion of polypropylene Ether silicone oil can effectively improve the water absorption performance of the non-woven fabric, and ...

Embodiment 3

[0032] Internal non-woven fabric, including the following percentages by mass: high-fat polypropylene 10%, low-fat polypropylene 70%, emulsifier 0.6%, wetting agent 0.3%, wetting agent 0.3%, spreading agent 0.3%, antistatic Agent 1%, polyether silicone oil 0.2%, color masterbatch 1%, the balance is distilled water.

[0033] In this embodiment, first, high-fat polypropylene, low-fat polypropylene and color masterbatch are hot-melt mixed, and then emulsifier, wetting agent, wetting agent, spreading agent, antistatic agent and polyether silicone oil are added and mixed Melt, the main component of the middle non-woven fabric is low-fat polypropylene, which makes the inner non-woven fabric have large pores after forming, and improves the water absorption and air permeability of the inner non-woven fabric. By adding a certain proportion of polyether silicone oil, it can effectively improve The water absorption performance of the non-woven fabric is improved, and then the melt is spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com