High-strength ultra-light two-phase structure magnesium-lithium alloy plate and preparation method thereof

A magnesium-lithium alloy and phase structure technology, applied in the field of metallurgical materials, can solve the problems of low alloy strength, achieve the effects of reducing plate defects, uniform size, and realizing dynamic recrystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the covering agent and refining agent in the embodiment of the present invention is to heat, melt and stir evenly after preparing each raw material, then casting and cooling into flakes, and finally grinding into powder and sealing for later use.

[0037]Before the warm rolling in the embodiment of the present invention, both the slab and the roll are preheated. The preheating temperature of the slab, that is, the rolling temperature, is 150-200°C, and the preheating time is 30-60min. In order to achieve constant temperature rolling, the roll is preheated The temperature is the same as the rolling temperature, and the preheating time is 2-3h.

[0038] The performance test in the embodiment of the present invention adopts the national standard GB / T6397-1986, and the tensile rate is 1mm / min.

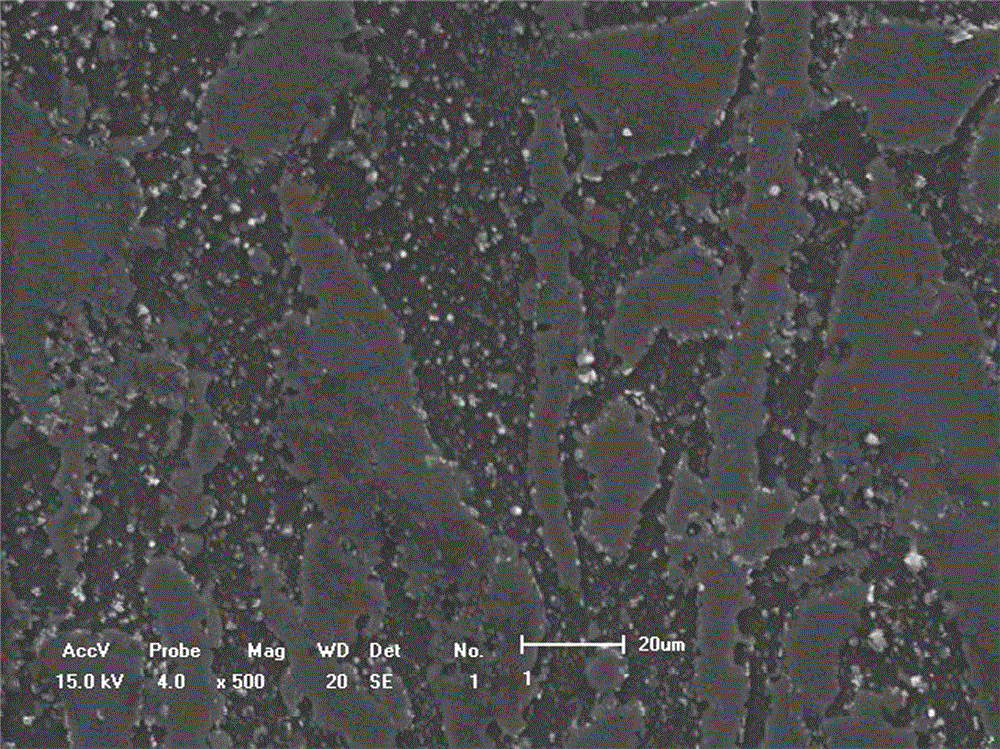

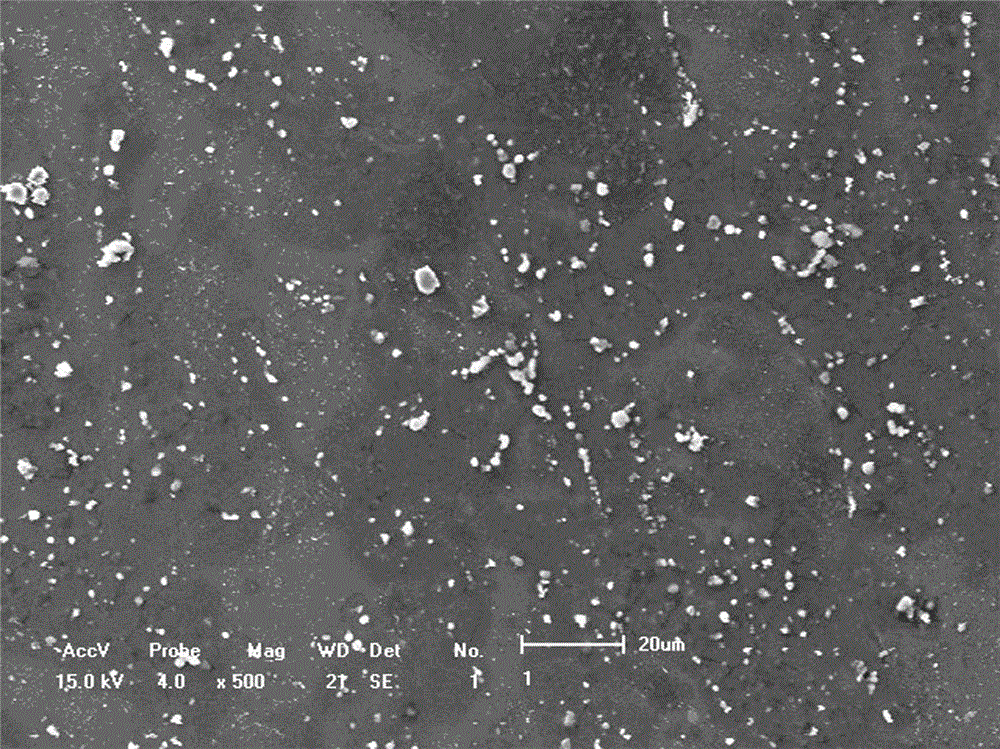

[0039] The equipment used for tissue observation in the embodiment of the present invention is a LEICA-DMR metallographic microscope.

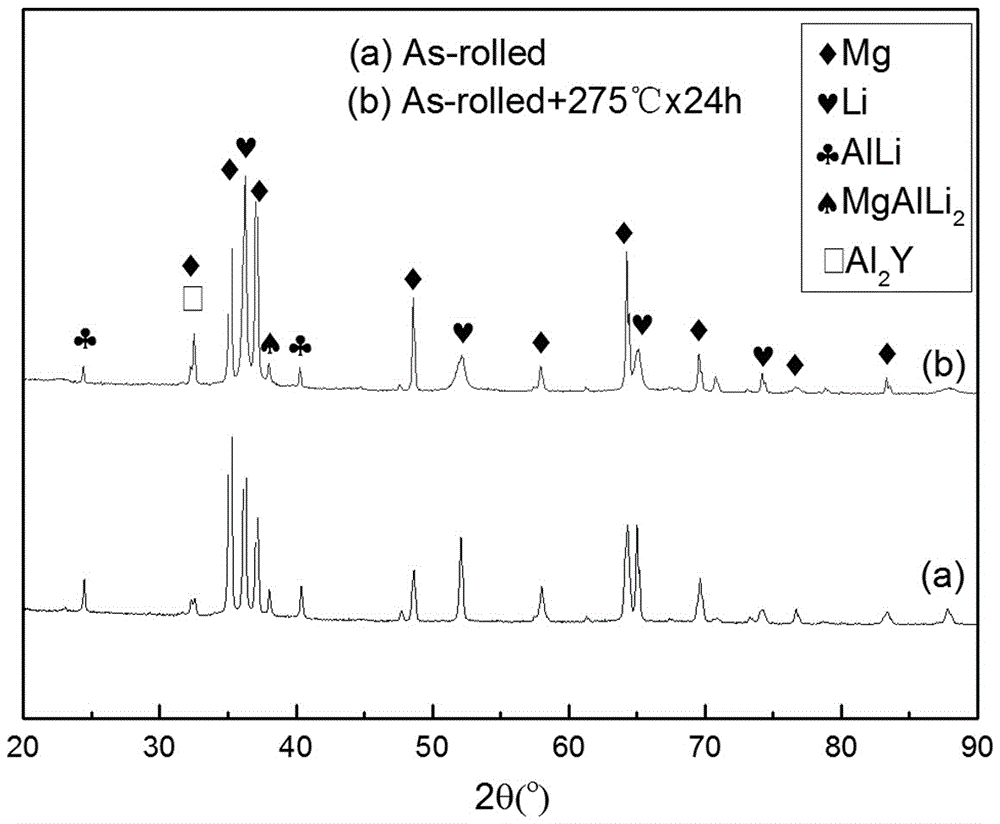

[0040] The equipme...

Embodiment 1

[0045] Prepare magnesium metal, lithium metal, aluminum metal, zinc metal and Mg-25%Y master alloy as raw materials;

[0046] Dry each raw material at 150±5°C for 30 minutes, then place the metal magnesium in a crucible and raise the temperature to 720±5°C, and form a magnesium melt after the metal magnesium is completely melted;

[0047] Place the magnesium melt under an argon protective atmosphere, place the dried Mg-25%Y master alloy, metal aluminum and metal zinc in the magnesium melt in turn, and spray a covering agent to cover the surface of the magnesium melt, and control the temperature at 710°C and stirring until all the metal in the crucible is melted to form a primary alloy melt;

[0048] Under the protective atmosphere of argon, the temperature of the primary alloy melt was lowered to 670 ° C, and the metal lithium wrapped in aluminum foil was pressed into the primary alloy melt with a bell jar, and the covering agent was sprayed to cover the surface of the magnesi...

Embodiment 2

[0054] Method is with embodiment 1, and difference is:

[0055] (1) The raw materials were dried at 150±5°C for 60 minutes;

[0056] (2) After spraying the covering agent, control the temperature to 715°C;

[0057] (3) Cool the primary alloy melt to 680°C; add refining agent and stir up and down for 20s;

[0058] (4) The secondary alloy melt is left to stand for 9 minutes, and the temperature is controlled at 680°C; the composition of the magnesium-lithium alloy ingot is Li10.0%, Al 3.3%, Zn 2.0%, Y 0.15%, and the balance is Mg and impurities ;

[0059] (5) Heating the magnesium-lithium alloy ingot to 275°C for 7 hours;

[0060] (6) The warm rolling temperature is 200°C, the total reduction is 80%, the rolling speed is 2.5mm / s, and the total rolling passes are 20 passes;

[0061] (7) The rolled magnesium-lithium alloy plate is heated to 270°C and kept for 28 hours to complete the solution treatment; the tensile deformation of the stretching and leveling treatment is 3%;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com