Heat treatment method suitable for high-strength aluminum alloy thick plates

A heat treatment method and technology for aluminum alloy, applied in the field of aluminum alloy heat treatment process, can solve the problems of poor toughness, difference in structure, difference in performance, etc., and achieve the effect of improving fracture toughness, increasing supersaturation, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

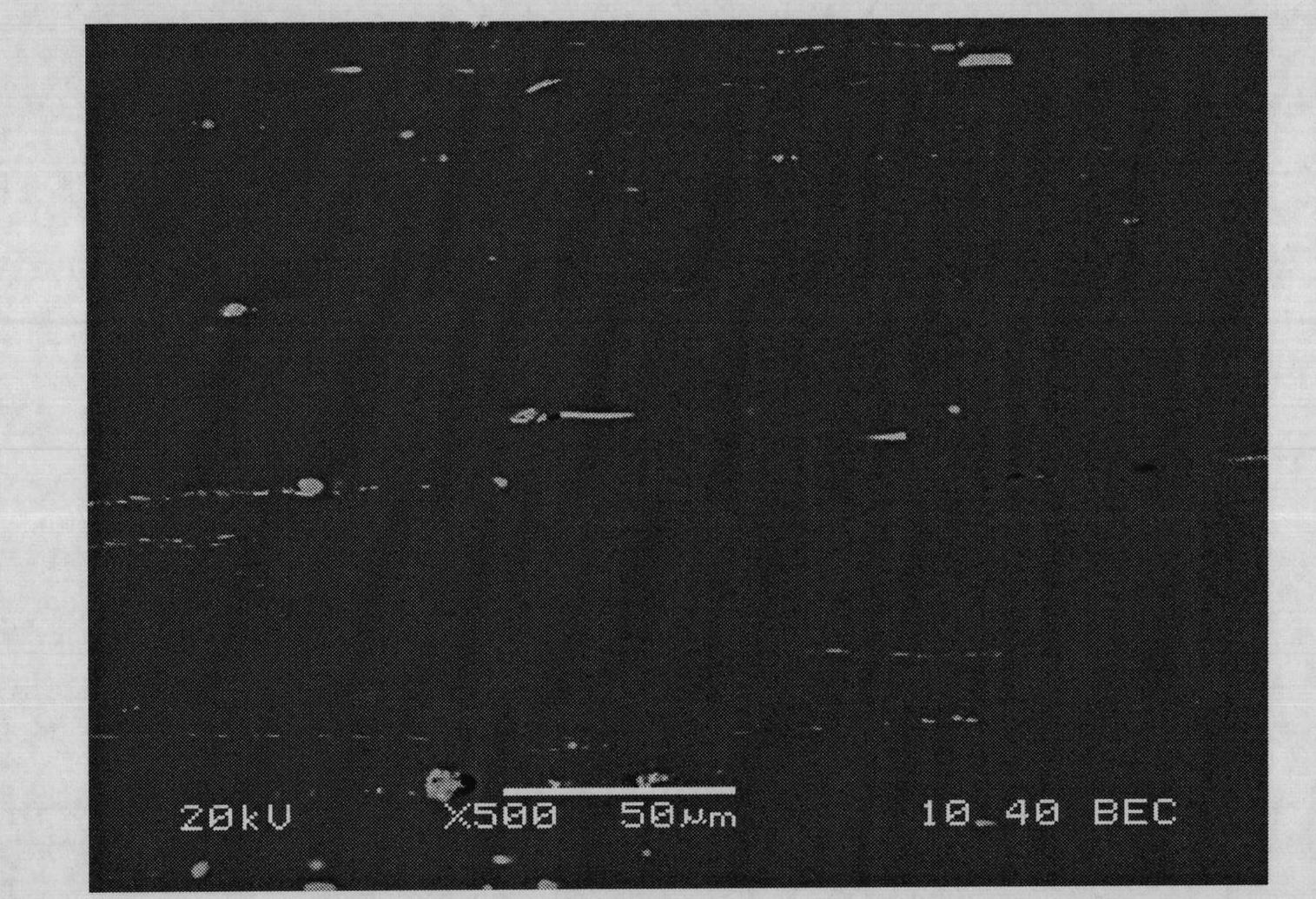

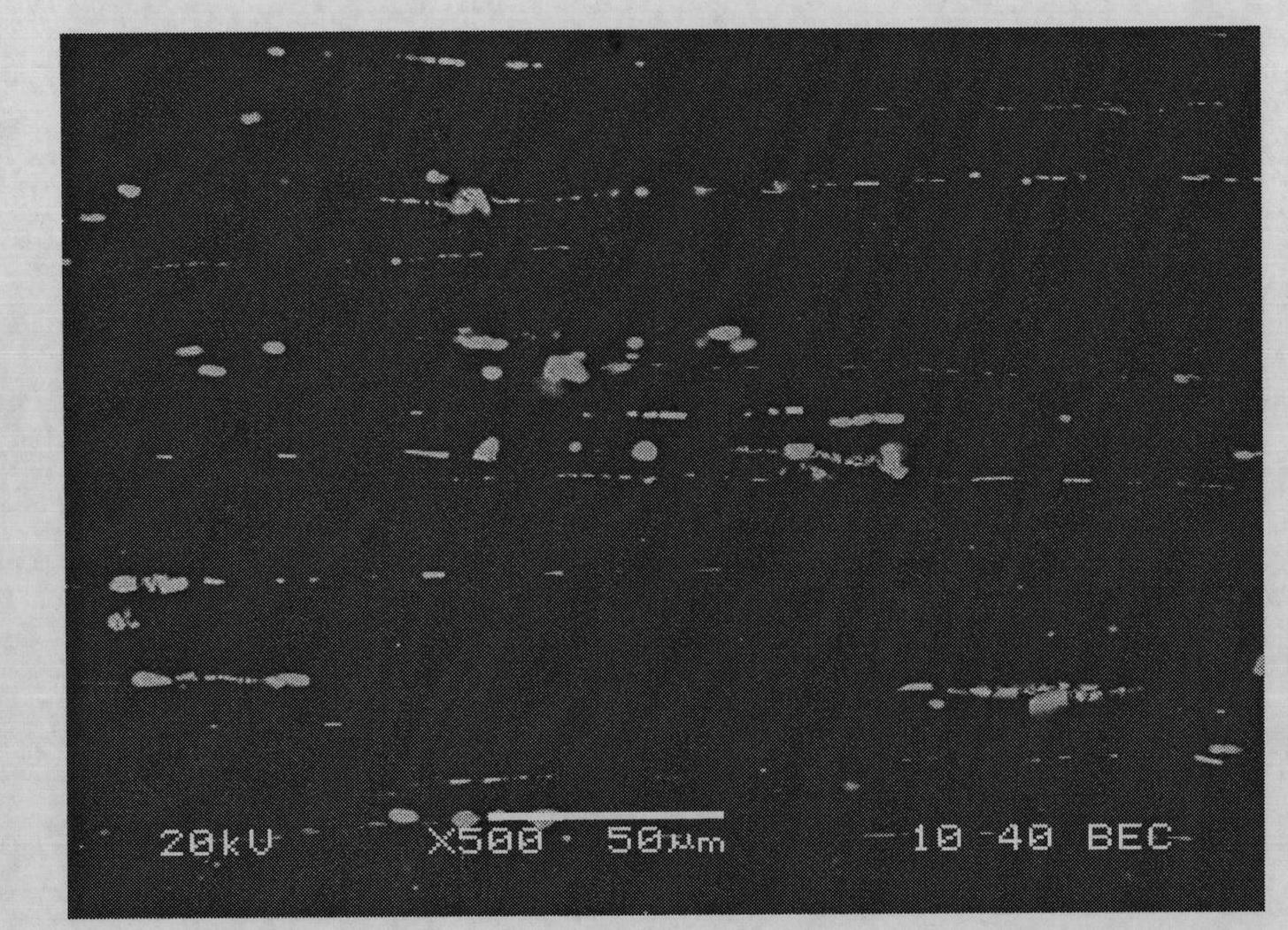

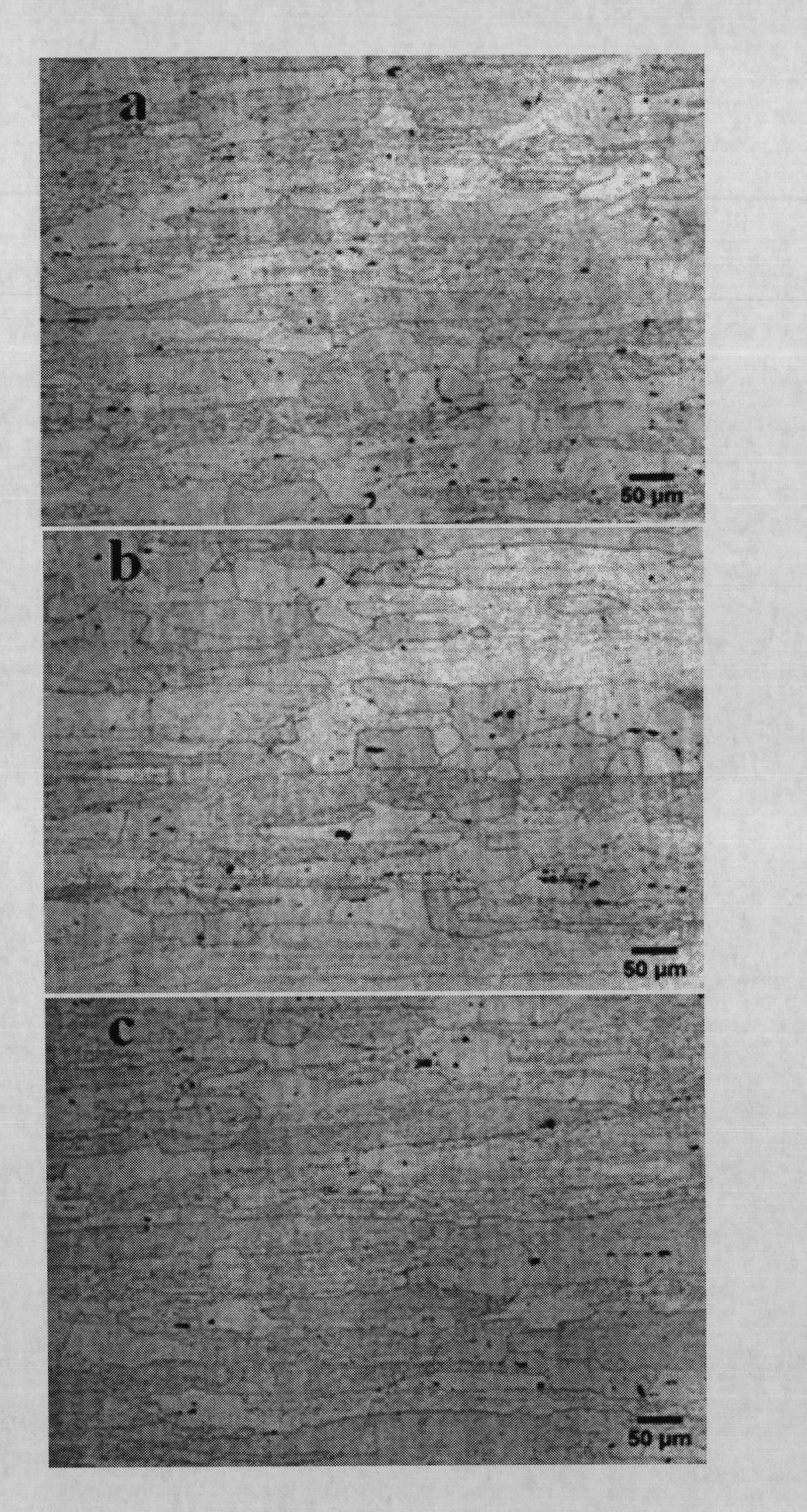

Image

Examples

Embodiment 1

[0037] Taking the 7150 aluminum alloy plate with 75% hot rolling deformation of 80mm as an example, its chemical composition (mass fraction%) is Zn 6.50%, Mg 2.35%, Cu 2.15%, Zr 0.10%, Fe 0.05%, Si 0.01% , Al balance.

[0038] Two-stage forced solution treatment: 7150 alloy is subjected to two-stage forced solution treatment, first-stage solution treatment at 425°C for 4 hours, and then second-stage enhanced solution treatment at 460°C for 6 hours.

[0039] After the two-stage forced solid solution, the quenching treatment is cooled to room temperature, the quenching medium is water at room temperature, and the quenching transfer time is less than 10s.

[0040] Pre-stretching is carried out within 4 hours after the two-stage forced solution quenching, and the pre-stretching deformation is 2%, so as to eliminate the quenching stress and increase the dislocation density in the alloy.

[0041] The pre-stretched alloy was aged at 145°C for 150min, and aged at 80°C for 48h after r...

Embodiment 2

[0043] Taking the 7150 aluminum alloy plate with 75% hot rolling deformation of 80mm as an example, its chemical composition (mass fraction%) is Zn 6.50%, Mg 2.35%, Cu 2.15%, Zr 0.10%, Fe 0.05%, Si 0.01% , Al balance.

[0044] Two-stage forced solution treatment: 7150 alloy is subjected to two-stage forced solution treatment, first-stage solution treatment at 435°C for 3 hours, and then second-stage enhanced solution treatment at 475°C for 5 hours.

[0045] After the two-stage forced solid solution, the quenching treatment is cooled to room temperature, the quenching medium is water at room temperature, and the quenching transfer time is less than 10s.

[0046] Pre-stretching is carried out within 3 hours after the two-stage forced solution quenching, and the pre-stretching deformation is 2.5%, so as to eliminate the quenching stress and increase the dislocation density in the alloy.

[0047] The pre-stretched alloy was aged at 170°C for 90min, and aged at 100°C for 32h after r...

Embodiment 3

[0049] Taking the 7150 aluminum alloy plate with 75% hot rolling deformation of 80mm as an example, its chemical composition (mass fraction%) is Zn 6.50%, Mg 2.35%, Cu 2.15%, Zr 0.10%, Fe 0.05%, Si 0.01% , Al balance.

[0050] Two-stage forced solution treatment: 7150 alloy is subjected to two-stage forced solution treatment, first-stage solution treatment at 450°C for 2 hours, and then second-stage enhanced solution treatment at 485°C for 4 hours.

[0051] After the two-stage forced solid solution, the quenching treatment is cooled to room temperature, the quenching medium is water at room temperature, and the quenching transfer time is less than 10s.

[0052] Pre-stretching is carried out within 1 hour after the two-stage forced solution quenching, and the pre-stretching deformation is 3.0%, so as to eliminate the quenching stress and increase the dislocation density in the alloy.

[0053] The pre-stretched alloy was aged at 185°C for 45min, and aged at 120°C for 24h after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com