Heat treatment method for improving obdurability of 7-series high strength aluminium alloy

A heat treatment method and aluminum alloy technology, applied in the field of heat treatment of metal materials, can solve the problems of high strength and poor toughness of high-strength aluminum alloys, and achieve the effects of improving fracture toughness, increasing supersaturation, and expanding the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

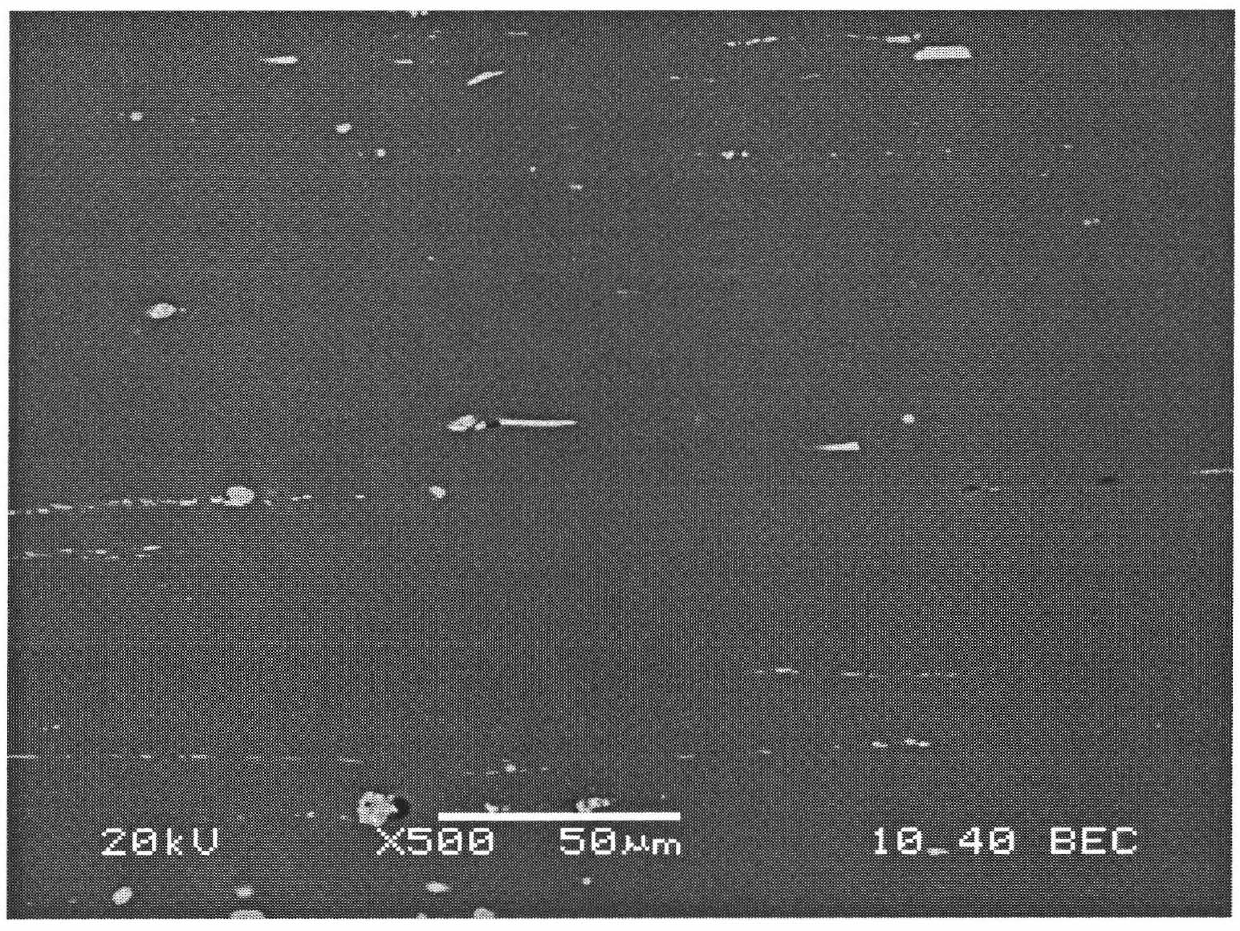

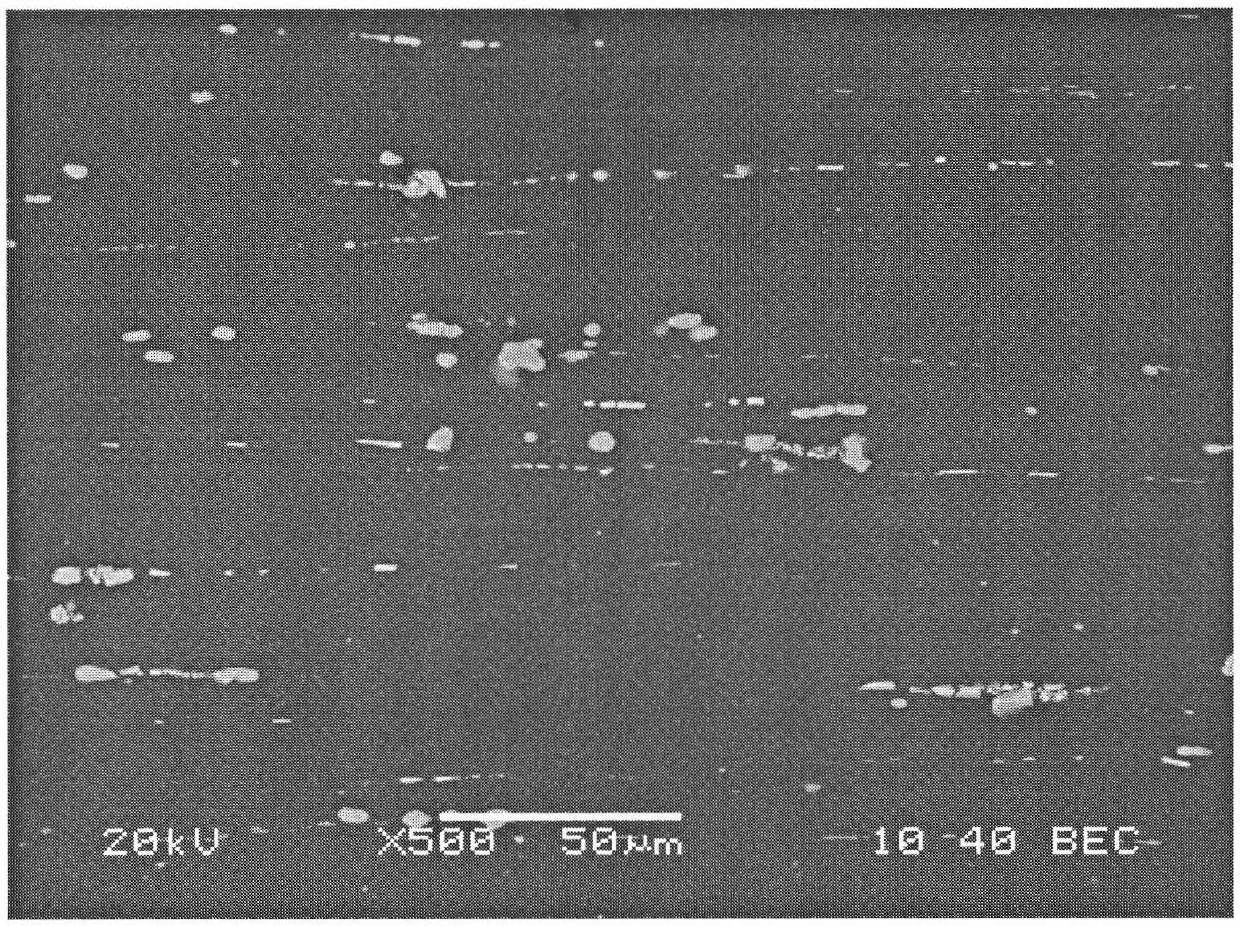

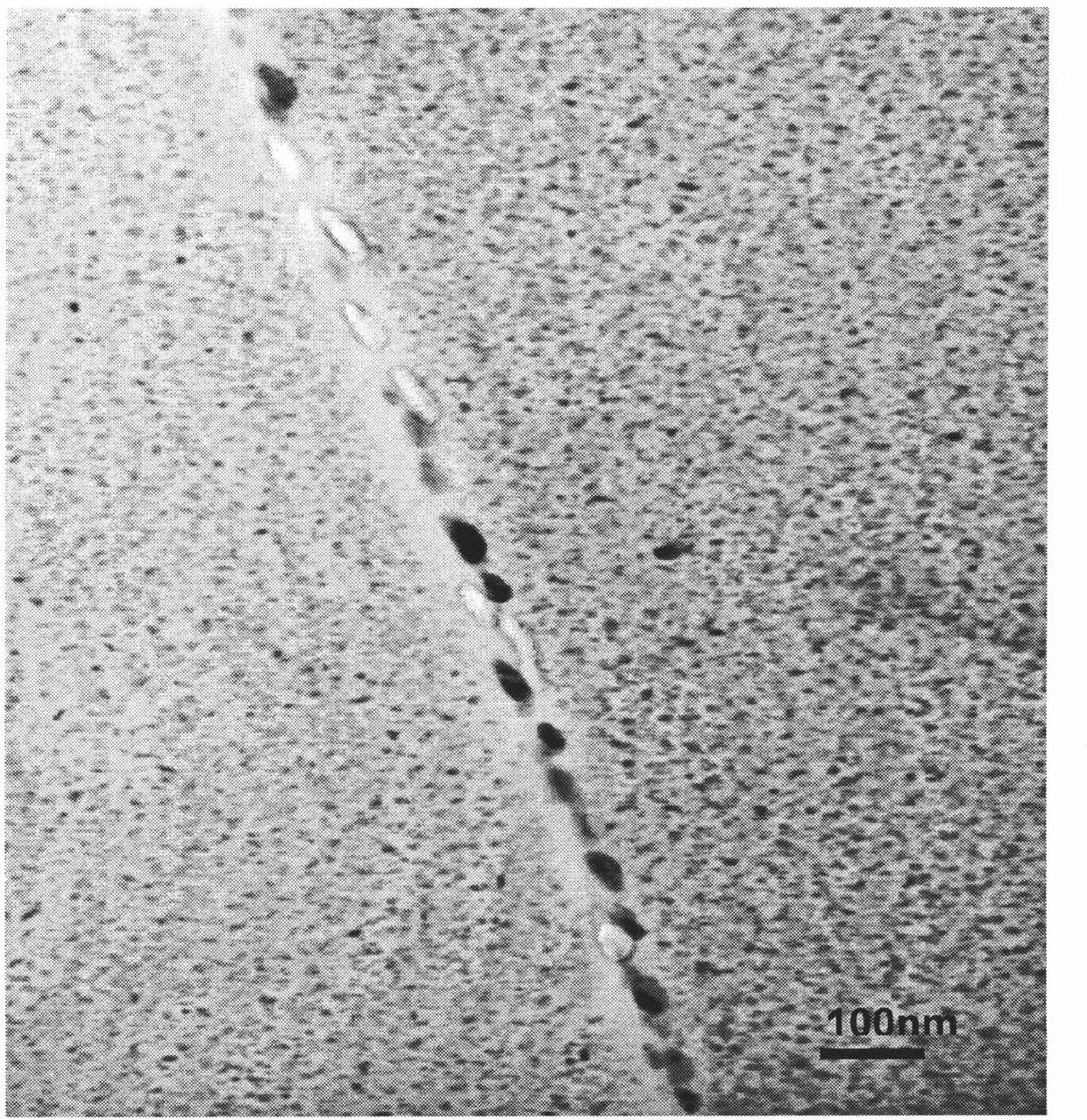

Method used

Image

Examples

Embodiment 1

[0036] Take the 7150 aluminum alloy sheet with 80% hot-rolled deformation after 25mm as an example, its chemical composition (mass fraction%) is Zn 6.45%, Mg 2.30%, Cu 2.10%, Zr 0.10%, Fe 0.05%, Si 0.01% , Al margin.

[0037] Two-stage forced solution treatment: Two-stage forced solution treatment of 7150 alloy, one-stage solution treatment at 420°C for 4 hours, and then two-stage strengthening solution treatment at 450°C for 4 hours.

[0038] After two-stage forced solution, the quenching treatment is cooled to room temperature, the quenching medium is room temperature water, and the quenching transfer time is less than 10s.

[0039] After the two-stage forced solution quenching treatment, pre-stretching is carried out within 4h, and the pre-stretching deformation is 1.5%, which can eliminate the quenching stress and increase the dislocation density in the alloy.

[0040] The pre-stretched alloy was aged at 160°C for 150 minutes, and then rapidly quenched at 80°C for 48 hours.

Embodiment 2

[0042] Take the 7150 aluminum alloy sheet with 80% hot-rolled deformation after 25mm as an example, its chemical composition (mass fraction%) is Zn 6.45%, Mg 2.30%, Cu 2.10%, Zr 0.10%, Fe 0.05%, Si 0.01% , Al margin.

[0043] Two-stage forced solution treatment: Two-stage forced solution treatment of 7150 alloy, one-stage solution treatment at 435℃ for 3 hours, and then two-stage strengthening solution treatment at 470℃ for 2.5 hours.

[0044] After two-stage forced solution, the quenching treatment is cooled to room temperature, the quenching medium is room temperature water, and the quenching transfer time is less than 10s.

[0045] After the two-stage forced solution quenching treatment, pre-stretching is carried out within 3 hours, and the pre-stretching deformation is 2.0%, which can eliminate the quenching stress and increase the dislocation density in the alloy.

[0046] The pre-stretched alloy was aged at 170°C for 90 minutes, and then rapidly quenched at 60°C for 32 hours.

Embodiment 3

[0048] Take the 7150 aluminum alloy sheet with 80% hot-rolled deformation after 25mm as an example, its chemical composition (mass fraction%) is Zn 6.45%, Mg 2.30%, Cu 2.10%, Zr 0.10%, Fe 0.05%, Si 0.01% , Al margin.

[0049] Two-stage forced solution treatment: Two-stage forced solution treatment of 7150 alloy, one-stage solution treatment at 450°C for 2 hours, and then two-stage strengthening solution treatment at 485°C for 2 hours.

[0050] After two-stage forced solution, the quenching treatment is cooled to room temperature, the quenching medium is room temperature water, and the quenching transfer time is less than 10s.

[0051] After two-stage forced solution quenching treatment, pre-stretching is carried out within 1h, and the pre-stretching deformation is 2.8%, which can eliminate the quenching stress and increase the dislocation density in the alloy.

[0052] The pre-stretched alloy was aged at 180°C for 60 minutes, and then rapidly quenched at 120°C for 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com