Heat treatment technology of high strength aluminium alloy

A technology of aluminum alloy and process, which is applied in the field of a heat treatment process of high-strength aluminum alloy, can solve the problems of poor corrosion resistance, insufficient strength reserve, high strength of aluminum alloy, etc., and achieve the effect of improving comprehensive mechanical properties and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Experimental environment: room temperature

[0016] Experimental equipment: ordinary heat treatment furnace, quenching water tank (water temperature is room temperature)

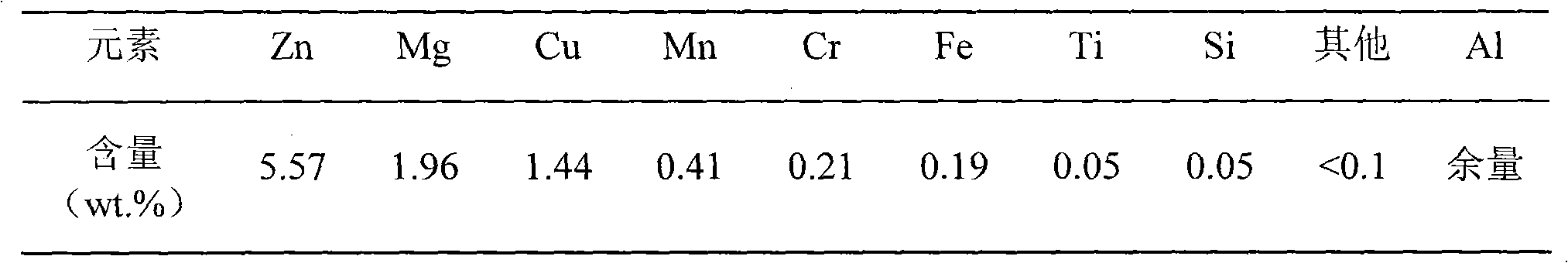

[0017] Experimental material: 7A04 aluminum alloy (composition shown in Table 1), 70mm diameter bar

[0018] Table 17A04 Aluminum Alloy Composition

[0019]

[0020] The heat treatment process is divided into four steps:

[0021] The first step is to perform solid solution treatment on the 7A04 aluminum alloy, keep the temperature at 465-480 °C, put the sample in, start timing when it reaches the solid solution temperature, keep it warm for 1 hour, and then quickly water quench (the quenching transfer time does not exceed 0.5 min);

[0022] The second step is to carry out the first-stage artificial aging treatment on the 7A04 aluminum alloy, keep the furnace temperature at 160°C, put the sample in, start timing when it reaches the first-stage aging temperature, keep it warm for 15 minutes, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com