Non-uniform hard alloy prepared by adopting close-packed batching mode and preparation method thereof

A cemented carbide, non-uniform technology, applied in the field of cemented carbide, can solve the problem of inability to judge the grain size and performance of the product, and has not seen the performance of non-uniform cemented carbide, etc., to achieve a wide range of grain distribution and good resistance. Abrasive, good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

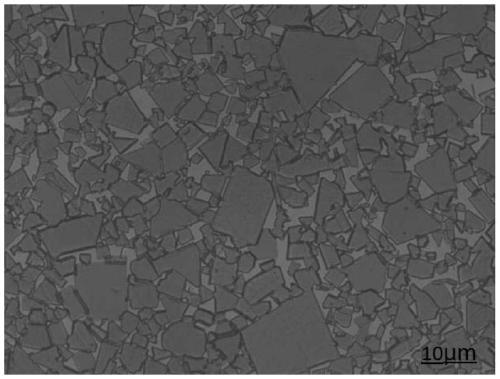

[0041] In this embodiment, a non-uniform (wide grain size distribution) cemented carbide is prepared, and the specific preparation process is as follows:

[0042] S1. Preparation of WC-10% Co: Put coarse-grained tungsten carbide, medium-grained tungsten carbide, ultra-fine or nano-particled tungsten carbide and bonding phase in a ball mill, the ball-to-material ratio is 2:1, and the ball-milling medium is absolute ethanol , the liquid-to-solid ratio is 0.3ml / g, and wet milled for 12 hours to obtain a wet milled mixture.

[0043] WC is composed of coarse grain WC, medium grain WC, superfine or nano grain WC, the mass ratio of the three is 6:3:1; the Fischer particle size of coarse grain WC is 30 μm, and the Fischer grain size of medium grain WC is 2 μm , the Fischer particle size of ultrafine or nanoparticle WC is 0.1 μm; the amount of Co added is 10% of the total WC mass.

[0044] S2. Press the wet-milled mixture under a pressure of 10 MPa, and then sinter the compacted compa...

Embodiment 2

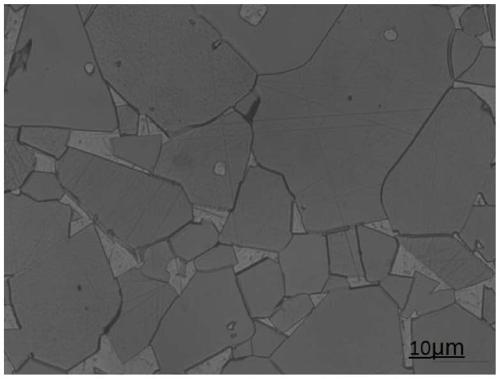

[0046] In this embodiment, a non-uniform (wide grain size distribution) cemented carbide is prepared, and the specific preparation process is as follows:

[0047] S1. Preparation of WC-11% Co: Put coarse-grained tungsten carbide, medium-grained tungsten carbide, ultra-fine or nano-particled tungsten carbide and bonding phase in a ball mill, the ball-to-material ratio is 2:1, and the ball-milling medium is absolute ethanol , the liquid-to-solid ratio is 0.3ml / g, and wet milled for 12 hours to obtain a wet milled mixture.

[0048] WC is composed of coarse grain WC, medium grain WC, superfine or nano grain WC, the mass ratio of the three is 7:2:1; the Fischer particle size of coarse grain WC is 30 μm, and the Fischer grain size of medium grain WC is 3 μm , the Fischer particle size of ultrafine or nanoparticle WC is 0.2 μm.

[0049] S2. Press the wet-milled mixture under a pressure of 10 MPa, and then sinter the compacted compact under vacuum conditions. The sintering temperatur...

Embodiment 3

[0051] In this embodiment, a non-uniform (wide grain size distribution) cemented carbide is prepared, and the specific preparation process is as follows:

[0052] S1. Preparation of WC-12% Co: Put coarse-grained tungsten carbide, medium-grained tungsten carbide, ultra-fine or nano-particled tungsten carbide and bonding phase in a ball mill, the ball-to-material ratio is 2:1, and the ball-milling medium is absolute ethanol , the liquid-to-material ratio is 0.3ml / g, and wet milled for 15 hours to obtain a wet milled mixture.

[0053] WC is composed of coarse grain WC, medium grain WC, superfine or nano grain WC, the mass ratio of the three is 6.5:2.5:1; the Fischer particle size of coarse grain WC is 30 μm, and that of medium grain WC is 3 μm , the Fischer particle size of ultrafine or nanoparticle WC is 0.1 μm.

[0054] S2. Press the wet-milled mixture under a pressure of 10 MPa, and then sinter the compacted green compact under vacuum conditions. The sintering temperature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com