Method for preparing nano-zinc oxide used as photocatalyst

A nano-zinc oxide, photocatalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as unfavorable production safety and environmental protection, irritating environment, corrosiveness, etc. Achieve the effect of alleviating the dehydration collapse effect, ensuring safety and environmental protection, and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

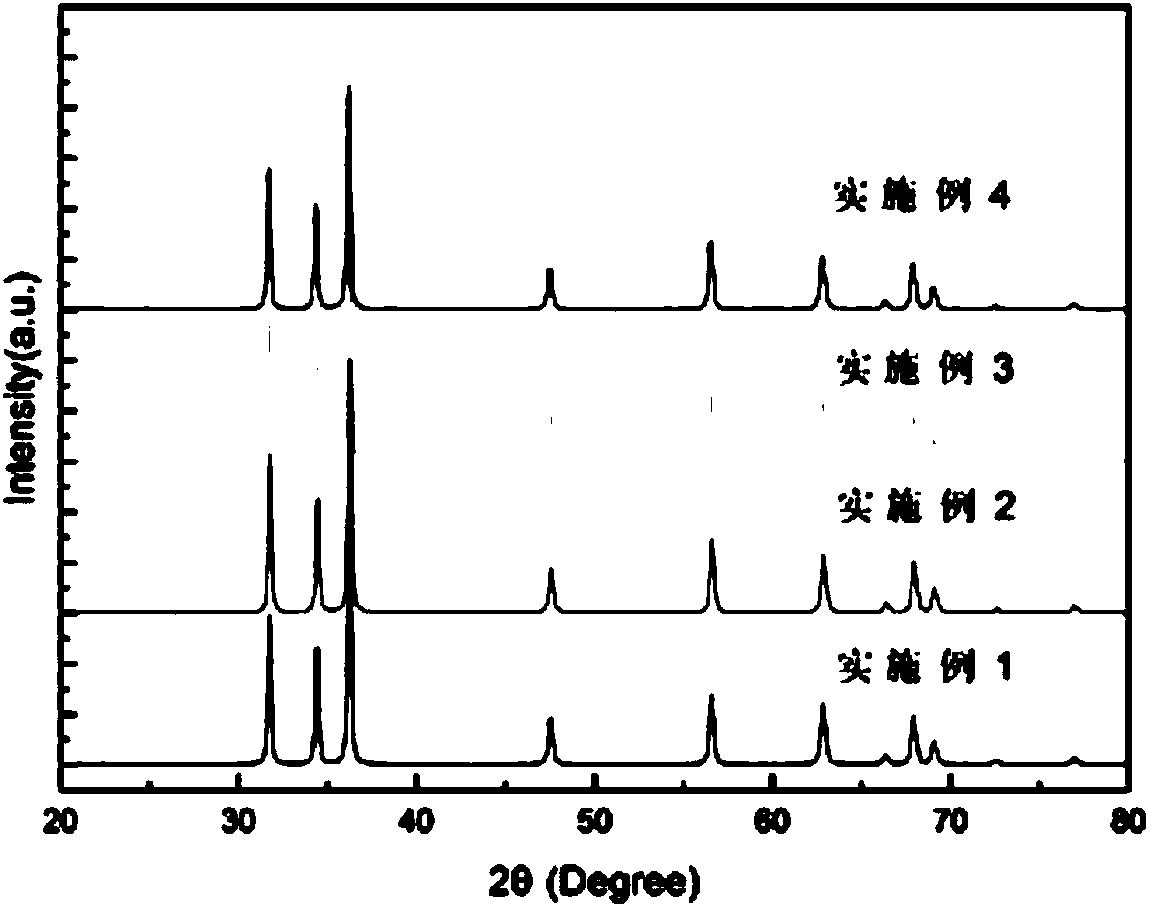

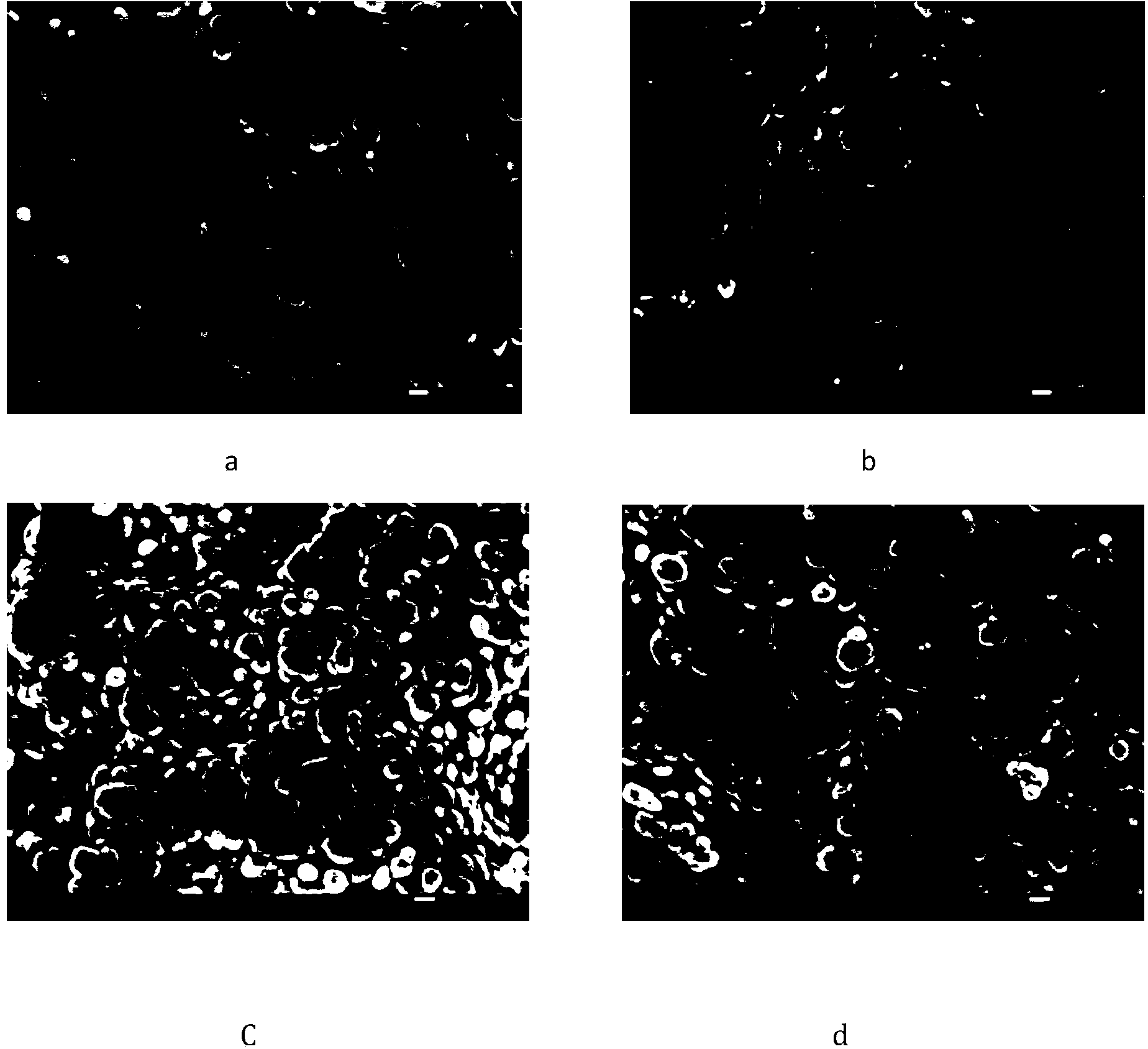

Embodiment 1

[0020] At indoor natural temperature (the inventor once prepared nano-ZnO in different seasons: summer, autumn and winter, and indoor temperature has no effect on the experimental results), stirring will mix 0.0171mol of zinc nitrate (5.022g), 0.0257mol of tartaric acid, 0.1112 1 mol of glucose was dissolved in 51 mL of deionized water to form a solution, and then 0.1265 mol of acrylamide and 0.0256 mol of methylenebisacrylamide were added in sequence, and stirred evenly to obtain a colorless transparent sol. The obtained colorless transparent sol was heated in a water bath at 90°C for 1 hour to obtain a white wet gel. The wet gel was placed in a blower constant temperature drying oven and dried at 120°C for 22 hours to obtain a xerogel. The xerogel was ground into After the powder is sintered at 600°C for 5 hours, nano-zinc oxide powder is obtained;

[0021] The molar ratio of tartaric acid to zinc nitrate is 1.50:1, the molar ratio of glucose to zinc nitrate is 6.5:1, the mo...

Embodiment 2

[0024] Dissolve 0.0171 mol of zinc nitrate (5.022 g), 0.0257 mol of citric acid, and 0.1112 glucose in 60 mL of deionized water under stirring at room temperature to form a solution, and then add 0.1282 mol of acrylamide and 0.0239 mol of methylenebisacrylamide in sequence , and stirred evenly to obtain a colorless transparent sol. Heat the obtained colorless transparent sol in a water bath at 86°C for 2 hours to obtain a white wet gel, place the wet gel in a blower constant temperature drying oven, and dry it at 100°C for 24 hours to obtain a dry gel, grind the dry gel After being powdered, it is sintered at 700°C for 4 hours to obtain nano-zinc oxide powder;

[0025] The molar ratio of citric acid to zinc nitrate is 1.5:1, the molar ratio of glucose to zinc nitrate is 6.5:1, the molar ratio of acrylamide to zinc nitrate is 7.5:1, and the methylene bis The molar ratio of acrylamide to zinc nitrate is 1.4:1, and the ratio of the volume of deionized water to the mass of zinc n...

Embodiment 3

[0028] Dissolve 0.0171 mol of zinc nitrate (5.022 g), 0.0128 mol of tartaric acid, and 0.1112 glucose in 51 mL of deionized water under stirring at room temperature to form a solution, then add 0.1299 mol of acrylamide, 0.0128 mol of methylenebisacrylamide and Stir evenly to obtain a colorless transparent sol. Heat the obtained colorless transparent sol in a water bath at 88°C for 1.5 hours to obtain a white wet gel, place the wet gel in a blower constant temperature drying oven, and dry it at 100°C for 24 hours to obtain a dry gel, grind the dry gel After being powdered, sinter at 650°C for 5 hours to obtain nano-zinc oxide powder;

[0029] The molar ratio of tartaric acid to zinc nitrate is 0.75:1, the molar ratio of glucose to zinc nitrate is 6.5:1, the molar ratio of acrylamide to zinc nitrate is 7.6:1, and the methylenebisacrylic acid The molar ratio of amide to zinc nitrate is 1.5:1, and the ratio of the volume of deionized water to the mass of zinc nitrate is 10.20:1 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com