Production method of high-purity tantalum target material

A production method and tantalum target material technology, which is applied in the field of high-purity tantalum target material production, can solve the problems of not fundamentally solving the production cost and complicated process, and achieve uniform grain size distribution, simple process, and good film formation performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

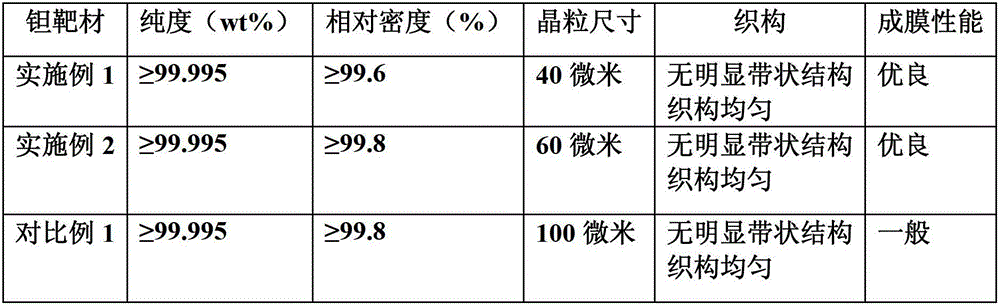

Examples

Embodiment 1

[0025] This example provides a production method of a high-purity tantalum alloy target, which includes the following steps in sequence:

[0026] (1) Select tantalum ingots with a purity greater than 99.999% electron beam melting as raw materials, cut the tantalum ingots into blocks, the size of the blocks is 5mm*10mm, put the tantalum blocks in the hydrogenation furnace, and pump the vacuum to 6.67×10 -3 Pa, then filled with 1atm hydrogen, and then evacuated to 6.67×10 -3 Pa, filled with hydrogen, adjust the pressure in the furnace to 10 -1 Pa level, start heating, the heating rate is 300°C / h, when the temperature reaches 450°C, keep the hydrogen pressure in the furnace at 1atm, continue to heat up, the cut-off temperature is 700°C, stop heating when the pressure in the furnace does not drop anymore, With the furnace cooling, the temperature is lower than 50 ℃ out of the furnace.

[0027] (2) Use a roller crusher to crush the tantalum particles that have been absorbed into ...

Embodiment 2

[0029] (1) Select tantalum ingots with a purity greater than 99.999% electron beam melting as raw materials, cut the tantalum ingots into blocks, the size of the blocks is 8mm*10mm, put the tantalum blocks in the hydrogenation furnace, and pump the vacuum to 6.67×10 -3 Pa, then filled with 1atm hydrogen, and then evacuated to 6.67×10 -3 Pa, filled with hydrogen, adjust the pressure in the furnace to 10 -1 Pa level, start heating, the heating rate is 300°C / h, when the temperature reaches 450°C, keep the hydrogen pressure in the furnace at 1atm, continue to heat up, the cut-off temperature is 600°C, stop heating when the pressure in the furnace does not drop anymore, With the furnace cooling, the temperature is lower than 50 ℃ out of the furnace.

[0030] (2) Use a roller crusher to crush the tantalum particles that have been absorbed into -100 mesh powder, and then use a jet mill to crush them into a -200 mesh powder. Put the tantalum hydride powder in a ladle, pump air, let ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com