Propenyl ethanoate catalyst and preparation method thereof

A technology of allyl acetate and catalyst, which is applied in the directions of catalyst activation/preparation, carboxylate preparation, chemical instruments and methods, etc., can solve the problems of low catalyst activity and selectivity, and improve the space-time yield and selectivity. , Good technical effect, uniform grain size distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Catalyst preparation

[0018] Step (a): get the liquid carbon dioxide solution 1200ml containing hexafluoroacetylacetonate palladium (II) and hexafluoroacetylacetonate copper (II) as dipping solution, the palladium content of this dipping solution is 2.75g / L, and the copper content is 0.625g / L , under the impregnation pressure of 69MPa and the impregnation temperature of 28°C, 1100ml of spherical silica support with a diameter of 4-6mm was impregnated to obtain the catalyst precursor I;

[0019] Step (b): then reduce the pressure, evaporate the liquid carbon dioxide in the catalyst precursor I at a rate of 0.3 ml (liquid carbon dioxide) / min, until the liquid carbon dioxide is evaporated to obtain the catalyst precursor II;

[0020] Step (c): reducing the catalyst precursor II in a hydrogen atmosphere, the hydrogen flow rate is 0.2 ml / min, and the reduction temperature is 75° C. to obtain the catalyst precursor III;

[0021] Step (d): infiltrate the catalyst precurs...

Embodiment 2

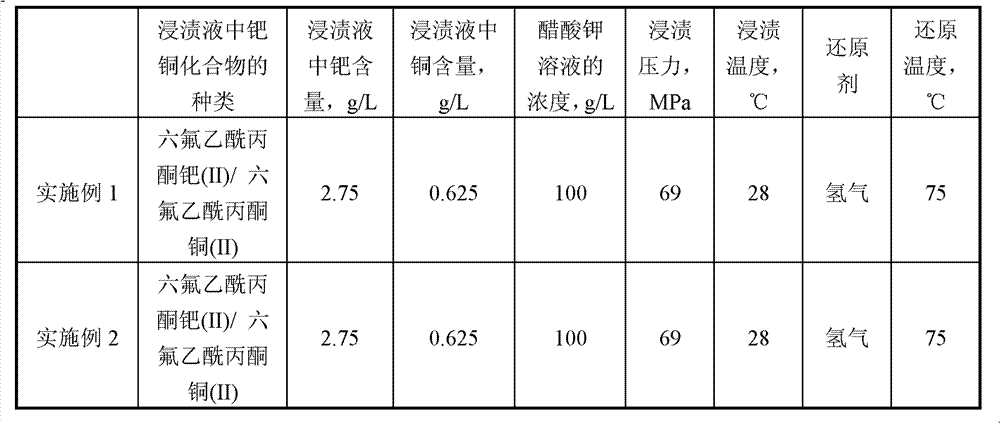

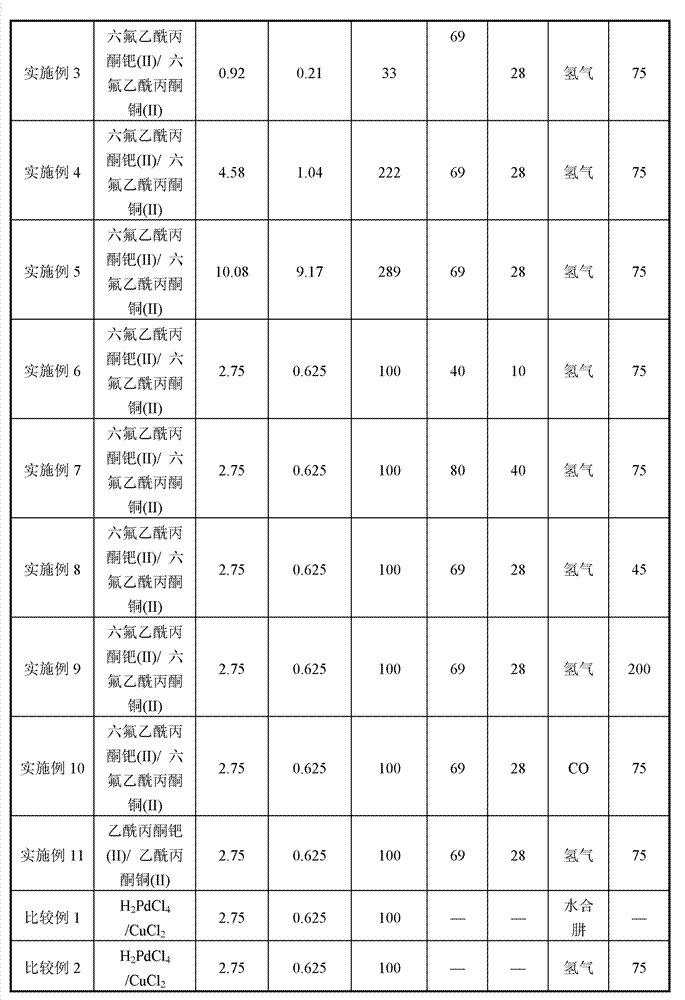

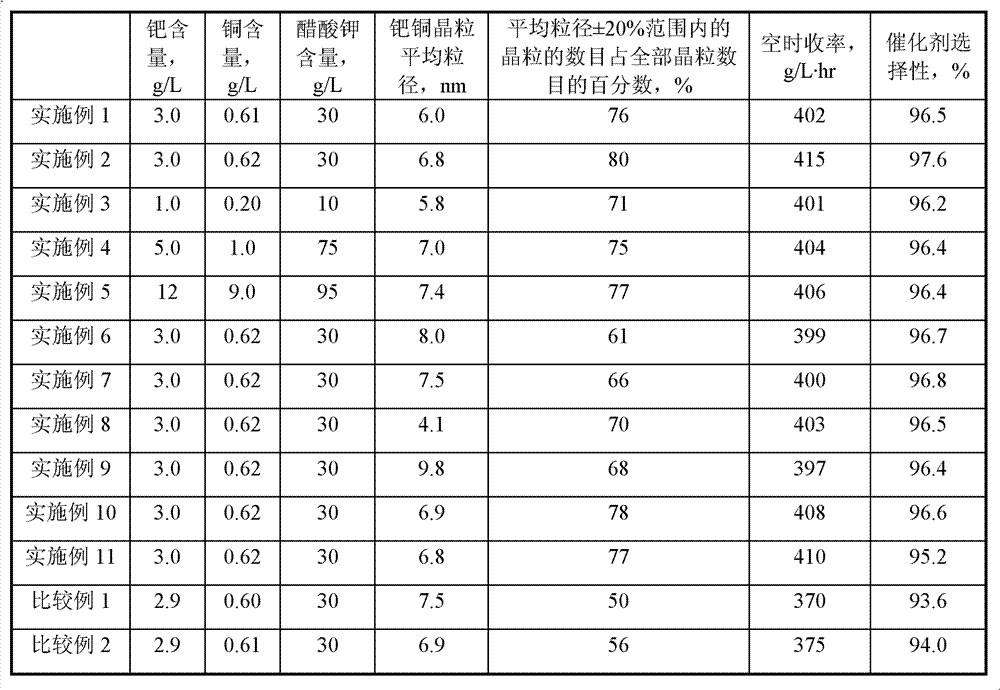

[0036] The steps are the same as in Example 1 except that the calcination step is added between the step (c) and the step (d). The roasting step is as follows: the catalyst precursor III is roasted in a nitrogen / acetic acid atmosphere, wherein the partial pressure of acetic acid accounts for 5% of the total pressure, the roasting temperature is 250° C., and the roasting time is 24hr. For the convenience of comparison, the preparation conditions of the catalyst are listed in Table 1, and the physical properties of the catalyst and the space-time yield and selectivity data of the catalyst are listed in Table 2.

Embodiment 3~11

[0038] Except for changing the concentration of palladium-copper in the liquid carbon dioxide dipping solution, the type of palladium-copper compound, the concentration of potassium acetate solution, the dipping pressure, the dipping temperature, the reducing gas and the reducing temperature, other operation steps are the same as in Example 2. For the convenience of comparison, the preparation conditions of the catalyst are listed in Table 1, and the physical properties of the catalyst and the space-time yield and selectivity data of the catalyst are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com