Preparation method of precious metal silver loaded nano-zinc oxide powder

A technology of nano-zinc oxide powder and precious metals, applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc. , harsh reaction conditions and other issues, to achieve the effect of improving particle size and chemical uniformity, avoiding hard agglomeration, and uniform grain size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

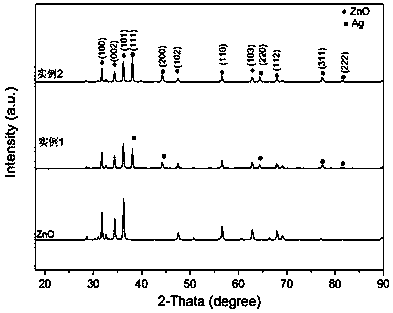

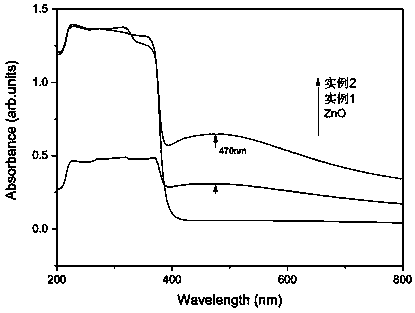

[0022] Weigh 1.0 g of polyvinyl alcohol (PVA) into a 100 mL flask, add 50 mL of deionized water, heat and stir the flask in an oil bath at 75°C for 30 min, and obtain a colorless and transparent PVA sol with a mass concentration of 20 mg / mL. The PVA aqueous solution was cooled to room temperature, and 4.0 g of zinc nitrate hexahydrate [Zn(NO 3 ) 2 ·6H 2 O] and 400mg silver nitrate, stirred for 30min to obtain polyvinyl alcohol-zinc nitrate-silver nitrate solution. Put the above solution into the refrigerator to fully pre-freeze, then place the cold trap temperature at -55°C and freeze-dry in a freeze dryer with a working pressure of 10Pa to obtain polyvinyl alcohol-zinc nitrate-silver nitrate (PVA-Zn-Ag ) brown foamy solid. Take an appropriate amount of the above solids and put them into a crucible, place them in a muffle furnace at 550°C for 2 hours and keep them warm for 6 hours for calcination to obtain silver-loaded nano-zinc oxide powder.

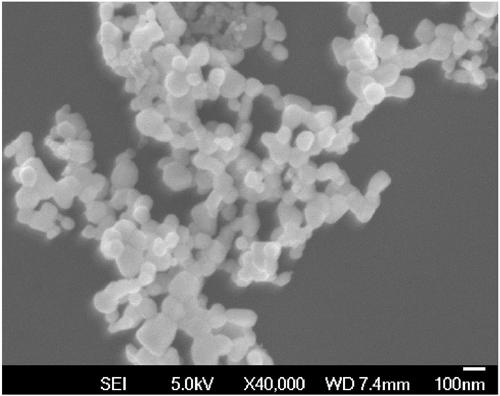

[0023] The SEM picture of t...

Embodiment 2

[0025] Weigh 1.5g of polyvinyl alcohol (PVA) into a 100mL flask, add 50mL of deionized water, heat and stir the flask in an oil bath at 75°C for 30min, and obtain a colorless and transparent PVA sol with a mass concentration of 30mg / mL. The PVA aqueous solution was cooled to room temperature, and 6.0 g of zinc nitrate hexahydrate [Zn(NO 3 ) 2 ·6H 2 O] and 600mg silver nitrate, stirred for 30min to obtain polyvinyl alcohol-zinc nitrate-silver nitrate solution. Put the above solution into the refrigerator to fully pre-freeze, then place the cold trap temperature at -55°C and freeze-dry in a freeze dryer with a working pressure of 10Pa to obtain polyvinyl alcohol-zinc nitrate-silver nitrate (PVA-Zn-Ag ) brown foamy solid. Take an appropriate amount of the above solids and put them into a crucible, place them in a muffle furnace at 550°C for 2 hours and keep them warm for 6 hours for calcination to obtain silver-loaded nano-zinc oxide powder.

Embodiment 3

[0030] Weigh 1.0 g of polyacrylamide (PAM) into a beaker, add 50 mL of deionized water, and stir for 30 min to obtain a colorless and transparent PAM sol with a mass concentration of 20 mg / mL. Add 4.0g zinc nitrate hexahydrate [Zn(NO 3 ) 2 ·6H 2 O] and 400mg silver nitrate, stirred for 30min to obtain polyacrylamide-zinc nitrate-silver nitrate solution. Put the above solution into the refrigerator to fully pre-freeze, then place the cold trap temperature at -55°C and freeze-dry in a freeze dryer with a working pressure of 10Pa to obtain polyacrylamide-zinc nitrate-silver nitrate (PAM-Zn-Ag ) brown foamy solid. Take an appropriate amount of the above solids and put them into a crucible, place them in a muffle furnace at 550°C for 2 hours and keep them warm for 6 hours for calcination to obtain silver-loaded nano-zinc oxide powder.

[0031] The SEM picture of the silver-loaded nano-zinc oxide powder prepared in this example is shown in Figure 4 . from Figure 4 It can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com