Self-spread high-temp synthesis process for preparing beta-silicon nitride whisker

A self-propagating high-temperature, whisker technology, which is applied in the preparation of β-Si3N4 whiskers and self-propagating high-temperature synthesis to prepare β-Si3N4 whiskers, which achieves the effects of convenient operation, low energy consumption and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

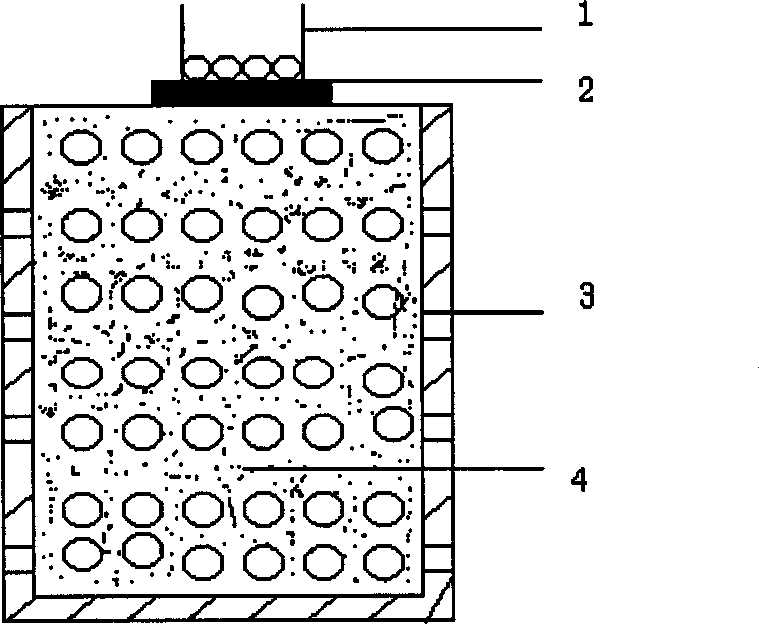

[0026] Silicon fume and α-Si 3 N 4 powder in a ratio of 1:1, then add Whisker Growth Aid Y 2 o 3 , the addition amount is Si powder and α-Si 3 N 4 5wt% of the total weight of the powder, the powder is evenly mixed and loosely packed in a porous graphite crucible with an outer diameter of φ60mm x an inner diameter of φ55mm x a height of φ60mm and the inner wall is coated with boron nitride, and the bulk density is 0.71g / cm 3 , and placed in a high-pressure container, filled with 5MPa nitrogen gas (purity 99.9%) after vacuuming, and self-propagating high-temperature synthesis of β-Si by energizing and igniting 3 N 4 For whiskers, the reaction time is no more than 5 minutes, and natural cooling is adopted after synthesis.

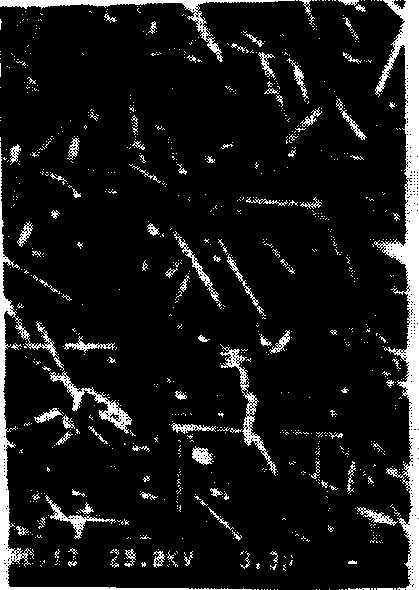

[0027] β-Si prepared by the above process 3 N 4 The yield of the whiskers is close to 100%, the length is 10-20 μm, the diameter is 1-2 μm, the average length-to-diameter ratio is ~10, the crystal structure is complete, and the surface is smooth and fr...

Embodiment 2

[0029] Silicon fume and α-Si 3 N 4 Powder mixed in a ratio of 7:3, then add the whisker growth aid La 2 o 3 , the addition amount is Si powder and α-Si 3 N 4 0.5wt% of the total weight of the powder, the powder is evenly mixed and loosely packed in a porous graphite crucible with an outer diameter of φ60mm x an inner diameter of φ55mm x a height of φ60mm and an inner wall coated with boron nitride, and the bulk density is 0.70g / cm 3 , and placed in a high-pressure container, filled with 5MPa nitrogen gas (purity 99.9%) after vacuuming, and self-propagating high-temperature synthesis of β-Si by energizing and igniting 3 N 4 For whiskers, the reaction time should not exceed 8 minutes, and natural cooling should be adopted after synthesis.

[0030] β-Si prepared by the above process 3 N 4 The yield of whiskers is close to 100%, the length is 8-13 μm, the diameter is between 0.7-1.5 μm, and the average aspect ratio is ~10. Its crystal structure is complete and its surface...

Embodiment approach 3-

[0031] Embodiment 3 - Self-propagating high-temperature synthesis of β-Si3 N 4 whiskers

[0032] Silicon fume and α-Si 3 N 4 Powder mixed in a ratio of 9:5, then add the whisker growth aid Gd 2 o 3 , the addition amount is Si powder and α-Si 3 N 4 3wt% of the total weight of the powder, the powder is evenly mixed and loosely packed in a porous graphite crucible with an outer diameter of φ60mm x an inner diameter of φ55mm x a height of φ60mm and the inner wall is coated with boron nitride, and the bulk density is 0.68g / cm 3 , and placed in a high-pressure container, filled with 5MPa nitrogen (purity 99.9%) after vacuuming, ignited and self-propagating combustion, and β-Si synthesized by igniting and self-propagating at high temperature 3 N 4 For whiskers, the reaction time is no more than 5 minutes, and natural cooling is adopted after synthesis.

[0033] β-Si prepared by the above process 3 N 4 The whisker yield is close to 100%, the length is 5-10 μm, the diameter i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com