Composite material of metal / ceramic metal, manufacturing method and application

A cermet and composite material technology, applied in the field of cermet materials and wear-resistant cermet materials, can solve the problems of low bonding strength, pollution, weakening bonding strength, etc., and achieve low raw material cost, high bonding strength and low manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment is a shovel tooth of an excavator, and the selected self-propagating high-temperature synthesis reaction system consists of:

[0046] Nickel Ni 42%

[0047] Titanium Ti 46%

[0048] Graphite C 12%.

[0049] The auxiliary component molybdenum Mo is added in the form of 55MoFe, and the added amount is 7.5% of the total weight of Ni, Ti and C.

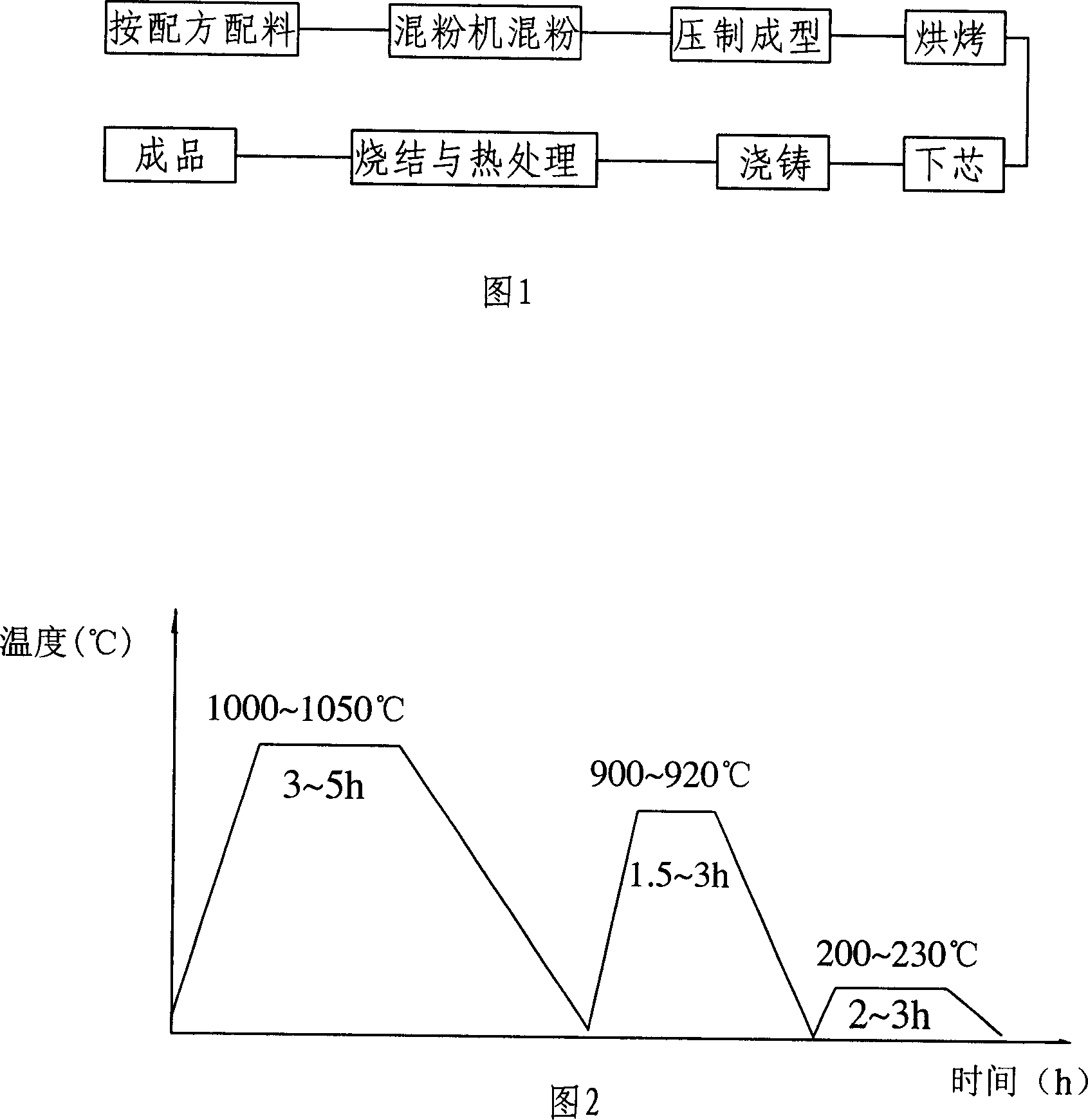

[0050] See Figure 1 and Figure 2, the specific manufacturing process is:

[0051] a. Prepare the raw materials according to the composition of the above-mentioned self-propagating high-temperature synthesis reaction system, and all raw materials are selected from powders below -100 mesh;

[0052] b. Preparation of prefabricated blocks. After the above-mentioned raw material powders are dry-mixed evenly, add 0.5-1.0% of the total powder weight of soybean oil as a binder, continue to mix evenly, take the specified weight and add it into the metal mold, and the metal mold is made in advance according to the shape a...

Embodiment 2

[0063] This embodiment is a shovel tooth of an excavator. The selected self-propagating high-temperature synthesis reaction system contains nickel Ni, titanium Ti, carbon C as the main components, and molybdenum Mo as the auxiliary component.

[0064] The main component is composed of:

[0065] Nickel Ni 35%

[0066] Titanium Ti 52%

[0067] Graphite C 13%.

[0068] The auxiliary component molybdenum Mo is added in the form of 55MoFe, and the added amount is 5% of the total weight of Ni, Ti and C.

[0069] The specific manufacturing process is:

[0070] a. Prepare the raw materials according to the composition of the above-mentioned self-propagating high-temperature synthesis reaction system, and all raw materials are selected from powders below -100 mesh;

[0071] b. Preparation of prefabricated blocks. After the above-mentioned raw material powders are dry-mixed evenly, add 0.5-1.0% of the total powder weight of soybean oil as a binder, continue to mix evenly, take the ...

Embodiment 3

[0076] This embodiment is a shovel tooth of an excavator. The selected self-propagating high-temperature synthesis reaction system contains nickel Ni, titanium Ti, carbon C as main components, and molybdenum Mo, RE, and Cu as auxiliary components.

[0077] The main component is composed of:

[0078] Nickel Ni 45%

[0079] Titanium Ti 44%

[0080] Graphite C 11%.

[0081] The auxiliary component molybdenum Mo is added in the form of 55MoFe, and the added amount is 7.5% of the total weight of Ni, Ti and C.

[0082] The auxiliary component RE is added in the form of 30RESiFe, and the added amount is 2% of the total weight of Ni, Ti, and C.

[0083] The auxiliary component Cu is added in the form of copper powder, and the added amount is 1% of the total weight of Ni, Ti and C.

[0084] The specific manufacturing process is:

[0085] a. Prepare the raw materials according to the composition of the above-mentioned self-propagating high-temperature synthesis reaction system, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com