Al-Ti-C crystal grain fining agent and its producing process

A grain refiner and manufacturing process technology, applied in the field of metal materials, can solve the problems of ingot deformation processing product quality decline, difficult process control, sensitive preparation process parameters, etc., and achieve strong resistance to grain refinement effect decline. , high activity and thermodynamic stability, the effect of improving the grain refinement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 30%Ti+7%C+63%Al,

[0022] (1) Ball milling and mixing for 24 hours, grinding balls Al 2 o 3 , the ratio of ball to material is 1 / 3;

[0023] (2) The mixture is cold-pressed into a prefabricated block with a relative compactness of 60%;

[0024] (3) Dry the prefabricated blocks at 150° C. for 1 hour.

[0025] In the reaction chamber of high-purity argon gas, a self-propagating reaction occurs to obtain a grain refiner. The size of TiC synthesized in the refiner is 3-4 μm, and the product is relatively dense. When the amount added to the aluminum liquid is 0.5wt%, The solidified sample has an equiaxed crystal structure, the grain size is refined to about 200 μm, and the stability of the grain refinement effect is about 0.5 hours.

Embodiment 2

[0027] 40%Ti+10%C+50%Al

[0028] (1) Ball milling and mixing for 10 hours, grinding balls Al 2 o 3 , the ratio of ball to material is 1 / 4;

[0029] (2) The mixture is cold-pressed into a prefabricated block with a relative compactness of 50%;

[0030] (3) Dry the prefabricated block at 100° C. for 1 hour.

[0031] The self-propagating reaction is the same as above, and the size of TiC synthesized in the refining agent is 2-3 μm, and the degree of looseness of the product is medium. When the amount added to the aluminum liquid is 0.2wt%, the solidified sample has an equiaxed crystal structure, and the grain size is fine. To 150 ~ 200μm, the stability of the grain refinement effect is 1 hour.

Embodiment 3

[0033] 56%Ti+14%C+30%Al

[0034] (1) Ball milling and mixing for 12 hours, grinding balls Al 2 o 3 , ball to material ratio 1 / 5,

[0035] (2) The mixture is cold-pressed into a prefabricated block with a relative compactness of 40%,

[0036] (3) The prefabricated blocks were dried at 150° C. for 0.5 hours.

[0037] The self-propagating reaction is the same as above, and the TiC grain size synthesized in the refiner is about 1 μm, and the product is loose and porous, with about 30% of pores. When the amount added to the aluminum liquid is 0.1wt%, the solidified sample has a fine Equiaxed crystal structure, grain size about 150μm.

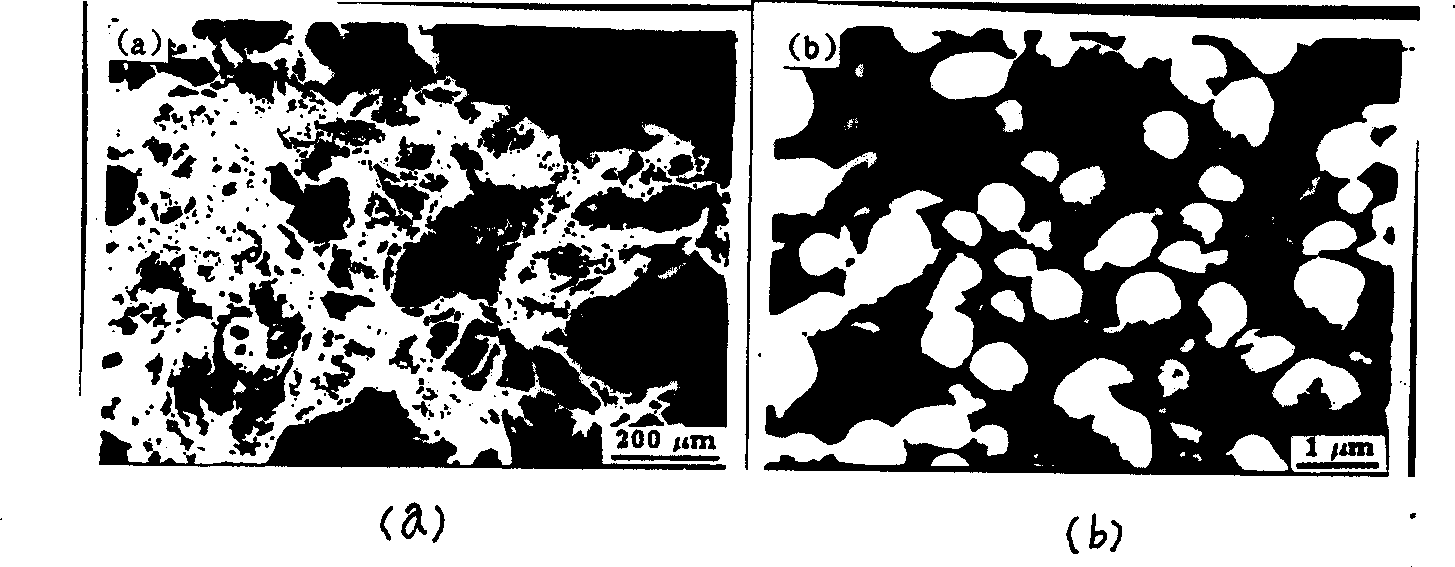

[0038] figure 1 (a) is the fracture morphology of the refiner, figure 1 (b) Its microstructure shows that TiC is a spherical particle of about 1 μm, and is distributed in an arc in the aluminum matrix, and no aggregation of TiC particles is found.

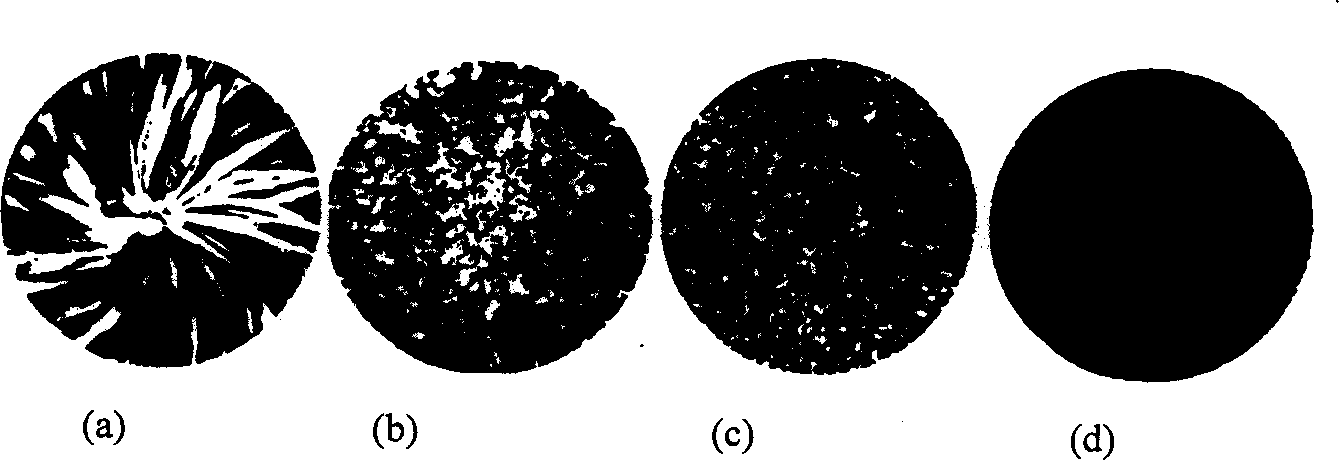

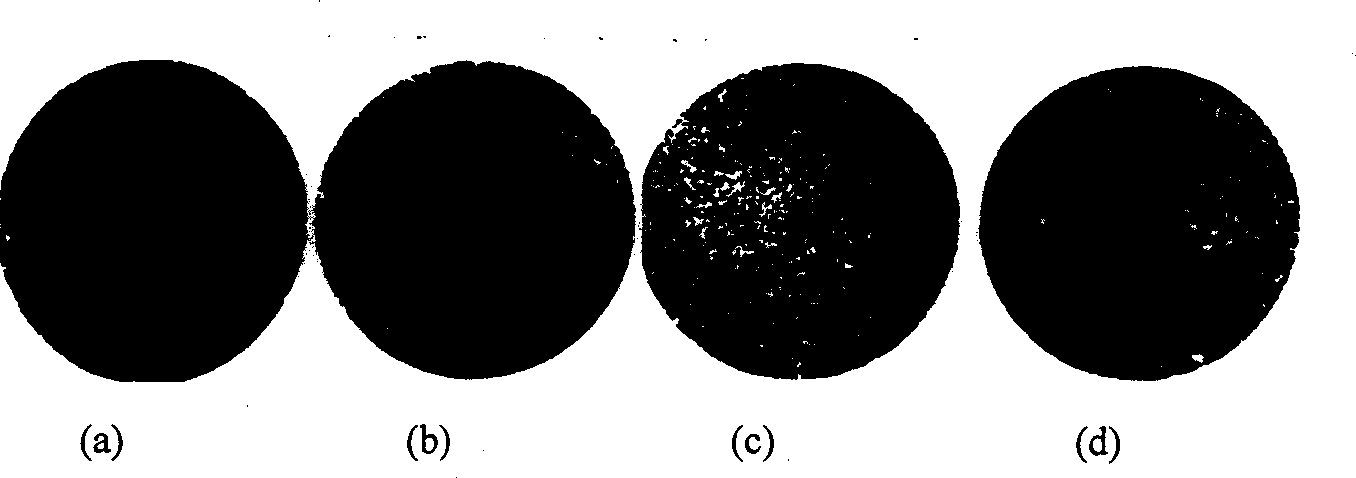

[0039]Using the synthesized Al-Ti-C grain refiner, the grain refinement effect experiment was c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com