Preparation method of TiB2 nanometer micrometer structure feeding for hot spraying

A nano-micron, thermal spraying technology, applied in the direction of coating, can solve the problems of low porosity, brittleness reduction, nano powder can not be thermally sprayed, etc., to achieve the effect of uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

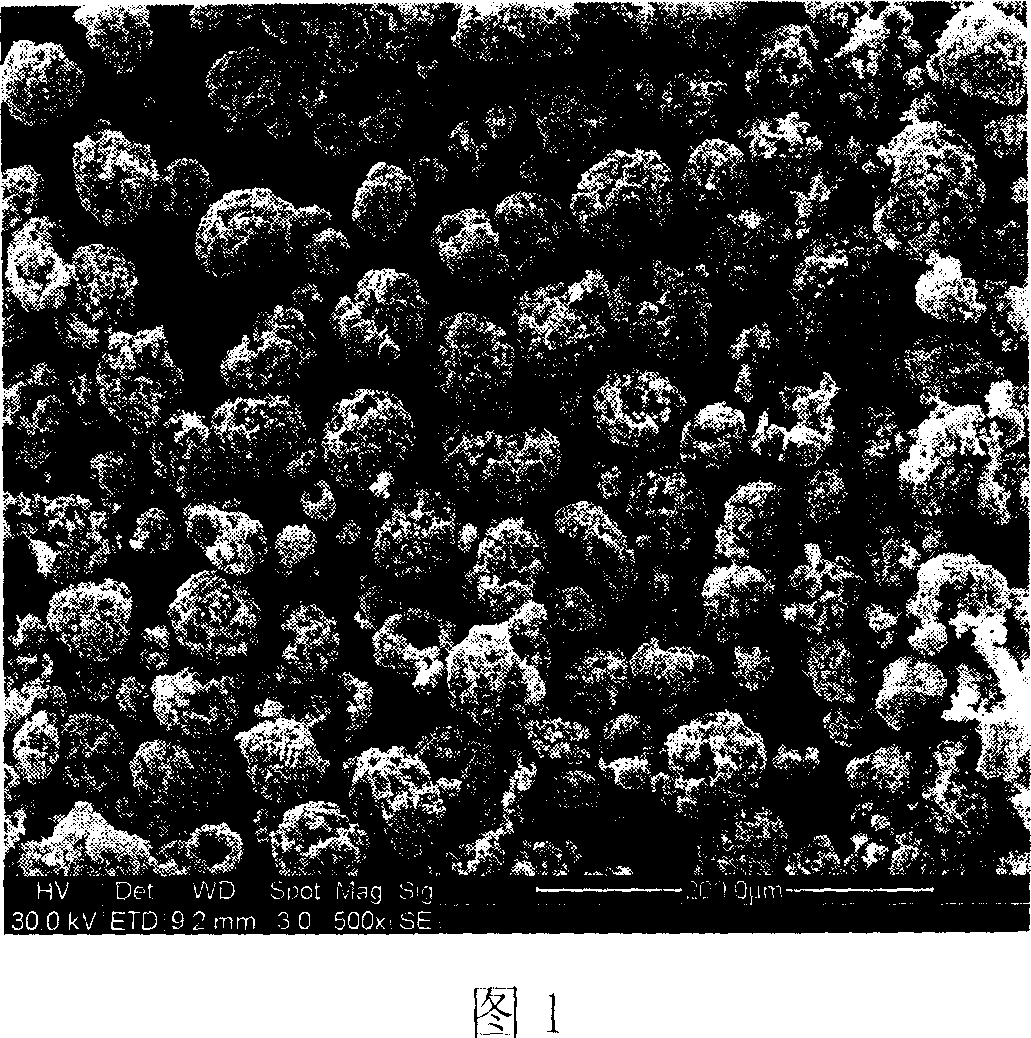

[0018] Example 1: TiB 2 / Al 2 o 3 Preparation of Nanostructured Feedstock

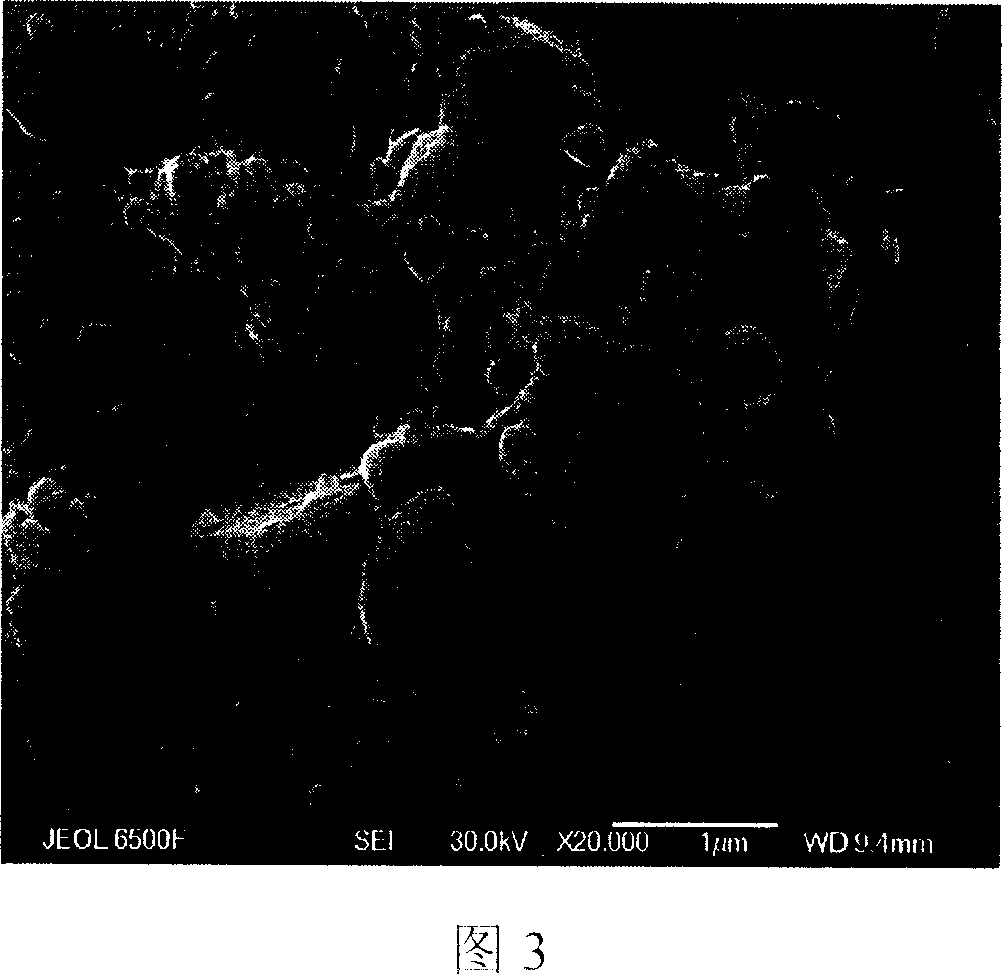

[0019] Take TiB with particle size less than 5μm 2 Powder 250g, Al with a particle size range of 80-200nm 2 o 3 Mix 50g of powder and carry out ball milling. The ball milling medium is deionized water, and then add deionized aqueous solution containing 23g of surfactant to prepare a slurry with a volume of 1L. Ball mill in a high-efficiency vertical ball mill for 1.5hr, and then use 20KHz Ultrasonic treatment for 15min. In this way, a suspension with a certain viscosity is prepared. Spray-dry the prepared suspension in a high-speed electric centrifugal spray-drying equipment. The spray drying parameters are selected as follows: air inlet temperature is 240°C, outlet temperature is 120°C; during the spray drying feeding process, the suspension is heated in a constant temperature water bath at 50°C, the feeding speed is controlled at 4L / hr, and the centrifugal disc speed is controlled at 35000r / mi...

Embodiment 2

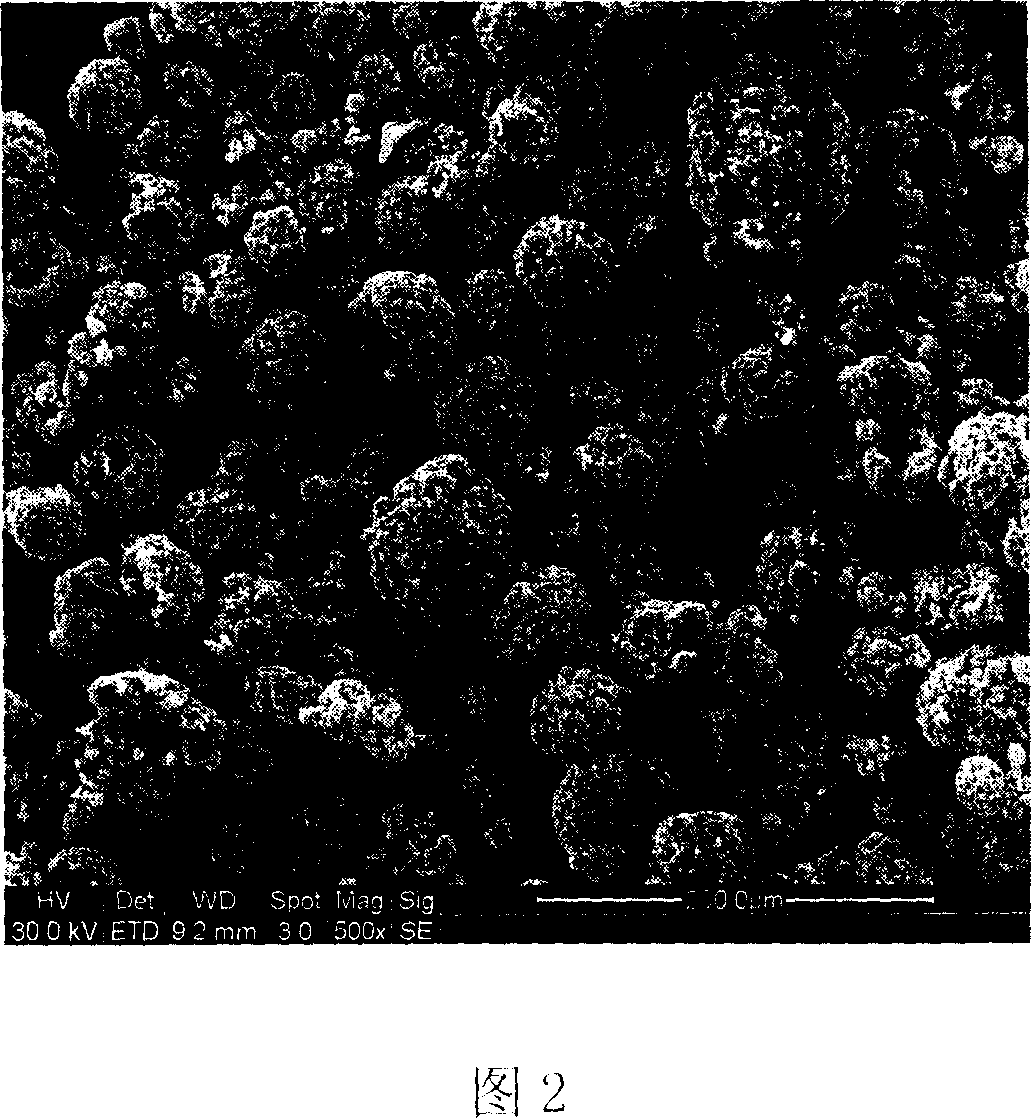

[0021] Example 2: TiB 2 / Preparation of SiC nano-microstructure feedstock

[0022] Take TiB with particle size less than 5μm 2 Mix 240g of SiC powder and 160g of SiC powder with a particle size less than 80nm, and perform ball milling for 1hr. Ball milling in a type ball mill for 1.5 hr, followed by 20 KHz ultrasonic treatment for 15 min. In this way, a suspension with a certain viscosity is prepared. Spray-dry the prepared suspension in a high-speed electric centrifugal spray-drying equipment. The spray drying parameters are selected as follows: air inlet temperature is 210°C, outlet temperature is 130°C; during the spray drying feeding process, the suspension is heated in a constant temperature water bath at 75°C, the feeding speed is controlled at 2L / hr, and the centrifugal disc speed is controlled at 25000r / min. Spray drying treatment can obtain 5~75μm TiB 2 / SiC agglomerated powder. The agglomerated powder is heat treated in a vacuum diffusion welding furnace with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com