Preparation method of a melt-electrospun composite fiber scaffold for bone repair and anti-infection

A composite fiber and anti-infection technology, which is applied in the fields of fiber chemical characteristics, prosthesis, artificial silk manufacturing, etc., can solve the problems of susceptibility to infection, achieve the effect of solving infection, accelerating bone repair, and improving hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

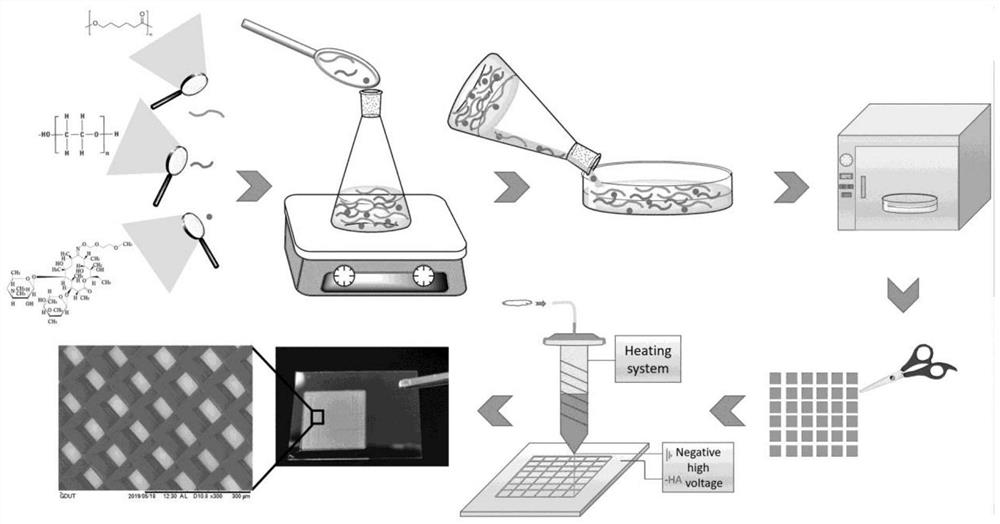

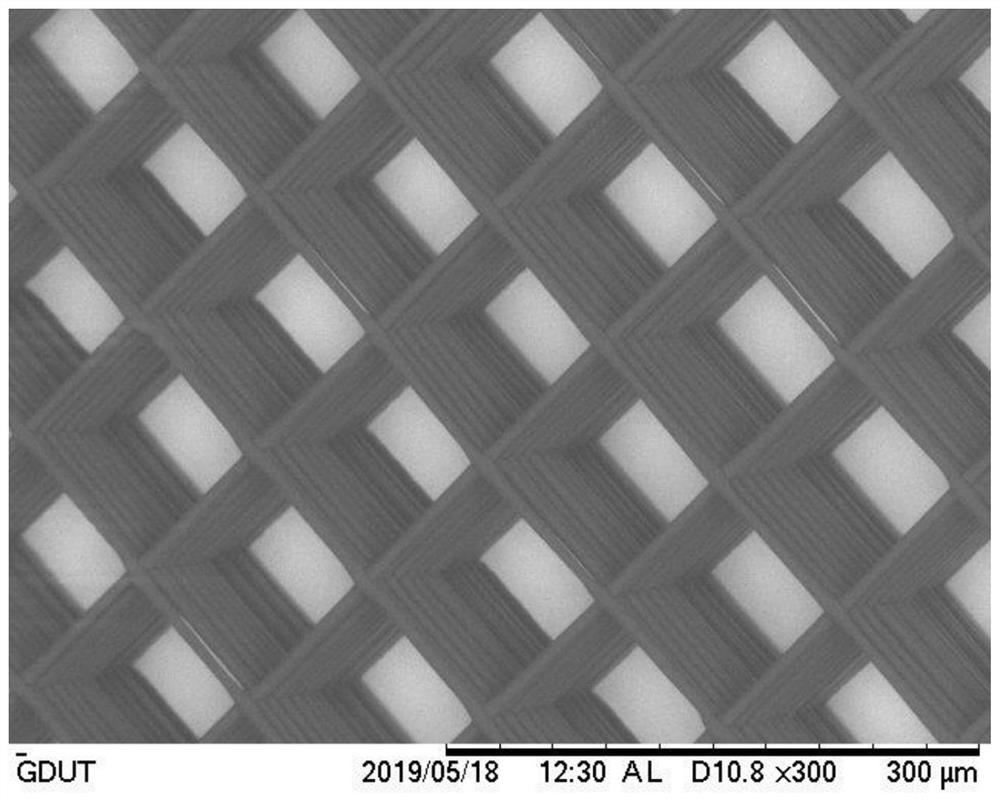

[0030] The invention provides a method for preparing a melt electrospun composite fiber scaffold for bone repair and anti-infection, comprising the following steps:

[0031] a) Mix polycaprolactone, polyethylene glycol and macrolide antibiotics uniformly in an organic solvent, evaporate the organic solvent and dry in vacuum to obtain a solid mixed material; the polycaprolactone, polyethylene glycol and macrolide The mass ratio of cyclic lactone antibiotics is 90:(0.1~20):(0.1~20);

[0032] b) Melt electrospinning the solid mixed material obtained in step a) to obtain a melt electrospun composite fiber scaffold for bone repair and anti-infection.

[0033] In the invention, polycaprolactone, polyethylene glycol and macrolide antibiotics are uniformly mixed in an organic solvent, evaporated to evaporate the organic solvent, and then vacuum-dried to obtain a solid mixed material. The present invention has no special limitation on the sources of the polycaprolactone (PCL) and poly...

Embodiment 1

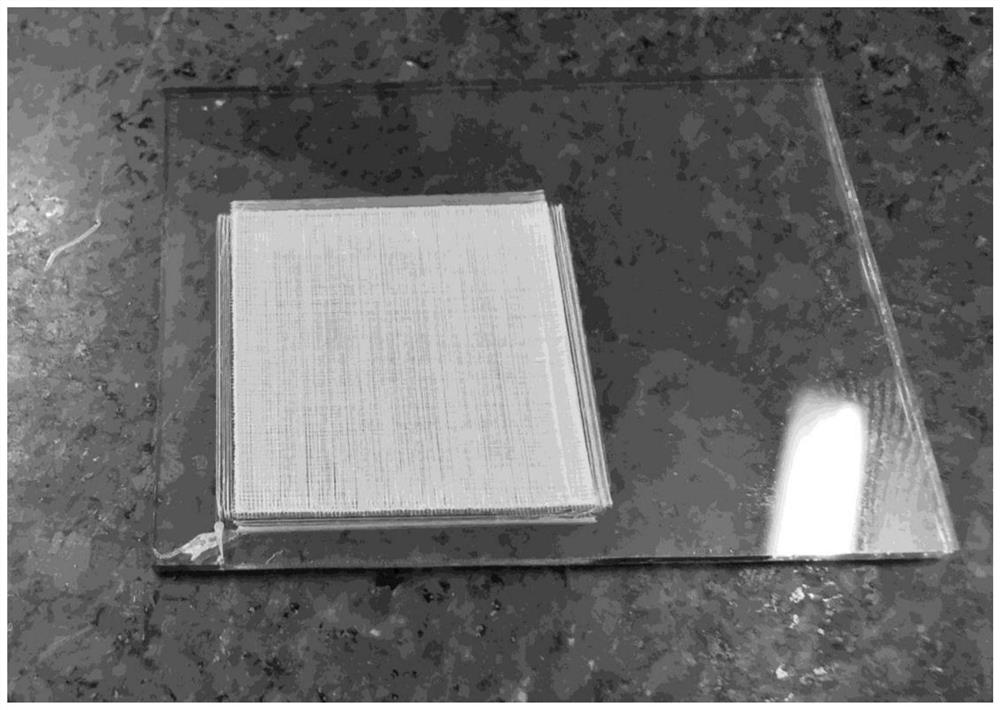

[0067] (1) be that 90% PCL by mass percentage composition, 5% PEG and 5% Roxithromycin by mass percentage composition are put into Erlenmeyer flask, raw material total mass is 5g; Add 30mL of organic solvent tetrahydrofuran, then stir in a magnetic stirrer at a temperature of 50°C and a speed of 400r / min for 24h, then pour the uniformly mixed material into a glass dish, and place it in a fume hood for 4h to evaporate the organic solvent tetrahydrofuran , and then put the glass dish containing the material into a vacuum drying oven at 80° C. for 3 hours to dry. After drying, take it out and let it stand for cooling to obtain a solid mixed material of PCL, PEG and roxithromycin.

[0068] (2) The solid mixed material obtained in step (1) is carried out to melt electrospinning, and the specific process is as follows:

[0069] Cut the solid mixed material into pieces with scissors and put it into the barrel; take a needle with an inner diameter of 0.45 mm, wash it with clean water ...

Embodiment 2

[0076] Using the same procedure as in Example 1, PCL with a mass percentage of 85%, PEG with a mass percentage of 10% and roxithromycin fiber scaffold with a mass percentage of 5% were prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com