Hot air anti-icing structure of composite engine guide vane with metal leading edge

A composite material and metal material technology, which is applied in the field of aero-engine guide vane hot air anti-icing structure and aero-engine leading edge component anti-icing structure design, which can solve the problem of low utilization rate of anti-icing hot air, poor thermal conductivity, affecting engine performance, etc. problem, to achieve the effect of improving engine thrust-to-weight ratio and engine performance, and reducing blade weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

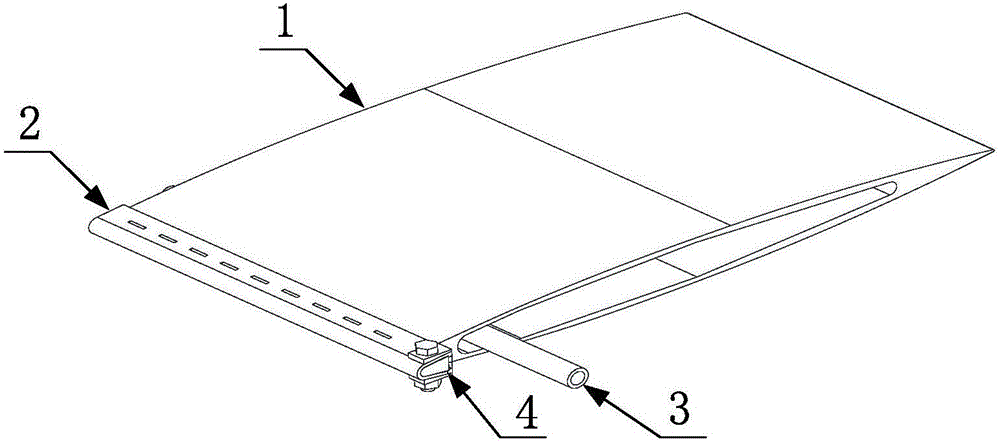

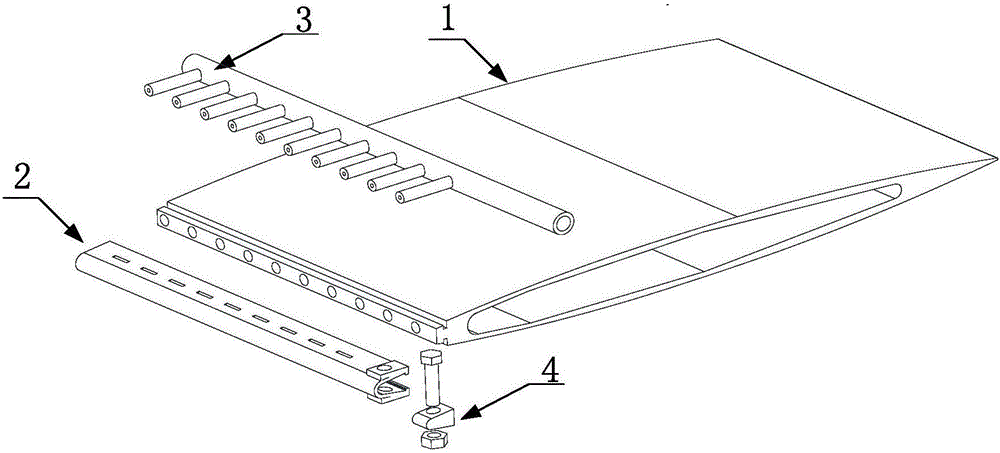

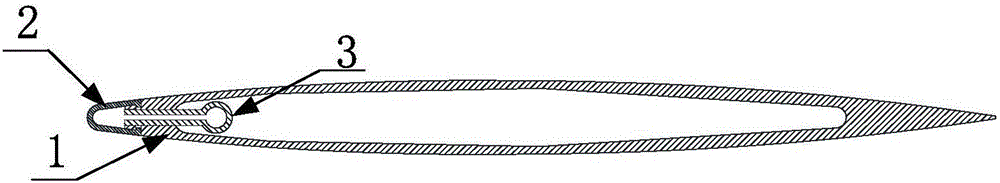

[0018] The invention is a hot gas anti-icing structure of a composite material engine guide vane with a metal leading edge, such as figure 1 , figure 2 , image 3 As shown, including blade base, blade leading edge, carbon fiber flute tube, the blade base is made of composite material, and the blade leading edge is made of metal material;

[0019] The main structure of the blade is a composite material blade matrix 1. A hollow structure anti-icing cavity A is provided inside the composite material blade matrix 1. Evenly distributed impact holes are arranged at the front end. The impact holes are connected to the anti-icing cavity A. Carbon fiber flute tube 3, the carbon fiber flute tube 3 includes a main pipe and a branch pipe, the branch pipe is vertically connected to the main pipe, the main pipe is located in the anti-icing chamber A, the branch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com