Biological anti-freezing protein water-based emulsion for preventing icy pavement as well as preparation method thereof

A technology of antifreeze protein and water-based emulsion, which is applied in the direction of protein coating, chemical instruments and methods, plant peptides, etc., can solve the problems of poor durability and complicated coating process, and achieve the effect of ensuring continuity and preventing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

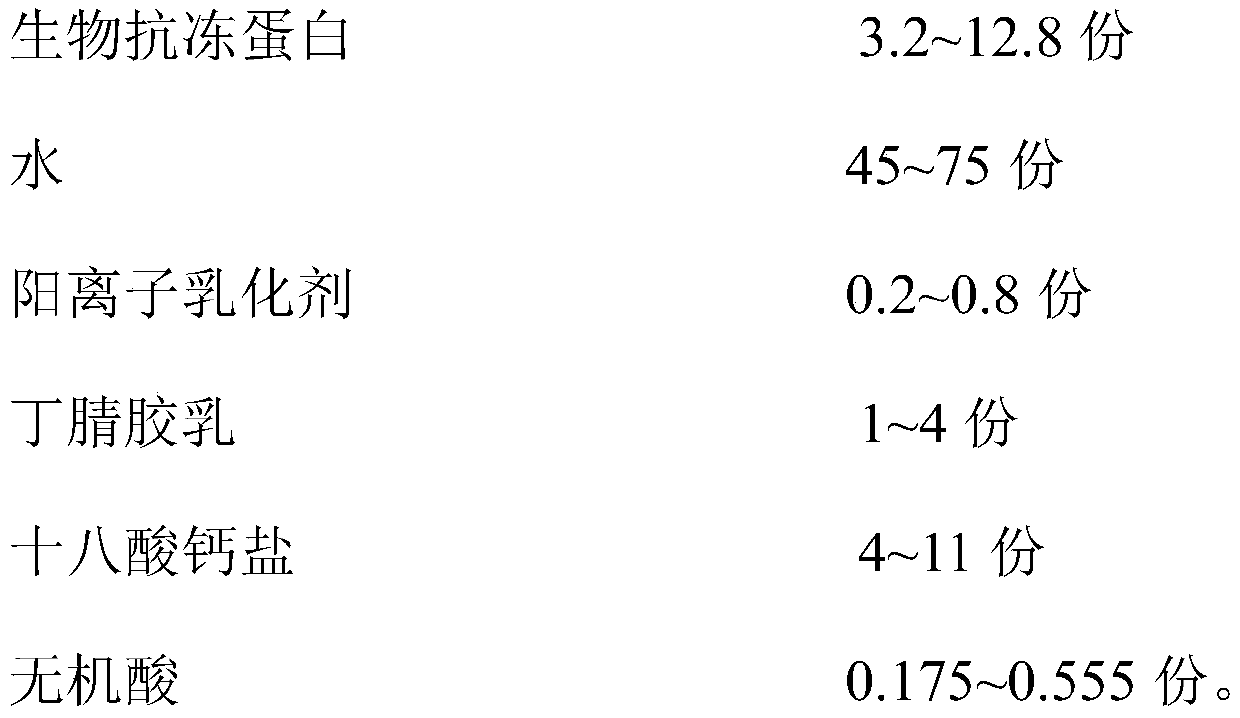

[0026]

[0027] Calcium stearate fusing point is more than 150 ℃ in this implementation, and its particle diameter is that the passing rate of the square hole sieve at mesh size 0.075mm is greater than 90%, and the pH that obtains emulsion is 2.

[0028] The preparation method of the biological antifreeze protein aqueous emulsion of above-mentioned prevention and treatment road surface icing, comprises the following steps:

[0029] 1) Weigh each component according to the mass ratio, and set aside;

[0030] 2) Heat the water to 60-80°C; specifically, it can be heated to 60°C, 70°C, 80°C, etc.; the water temperature can be between 60-80°C;

[0031] 3) first add cationic emulsifier to the water in step 2, and make the cationic emulsifier disperse evenly; then add mineral acid to the water to adjust the pH of the solution;

[0032] 4) Transfer the solution obtained in step 3 to a high-speed shear emulsifier, add nitrile latex and octadecanoic acid calcium salt, rotate and sti...

Embodiment 2

[0035]

[0036] Calcium stearate fusing point is more than 150 ℃ in the present implementation, and its particle diameter is that the passing rate of the square hole sieve of sieve size 0.075mm is greater than 90%, and the pH that obtains emulsion is 6.

[0037] The preparation method is the same as in Example 1.

Embodiment 3

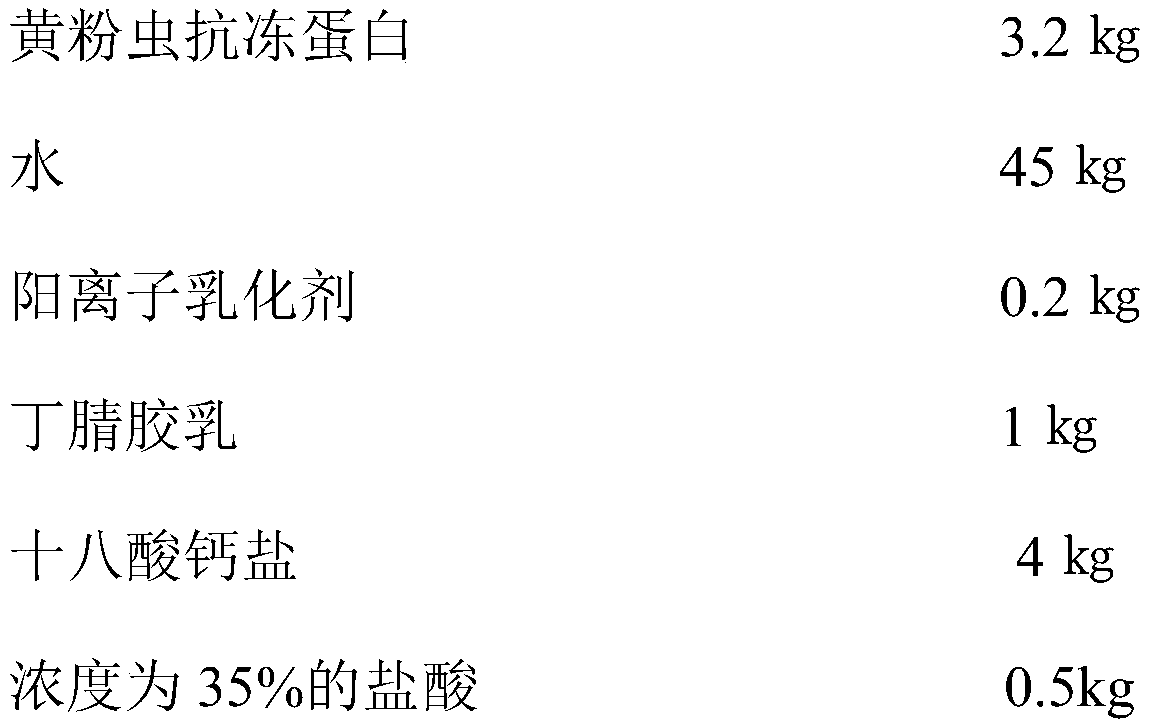

[0039]

[0040]

[0041] Calcium stearate fusing point is more than 150 ℃ in this implementation, and its particle diameter is that the passing rate of the square hole sieve at mesh size 0.075mm is greater than 90%, and the pH that obtains emulsion is 4.

[0042] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com