Anti-icing and abrasion-resistant coating suitable for blades of wind driven generator

A technology for wind turbine blades and wear-resistant coatings, which is applied in the field of anti-icing and wear-resistant coatings, wind turbine blade coatings, and can solve the problem that coatings cannot be anti-icing and wear-resistant at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

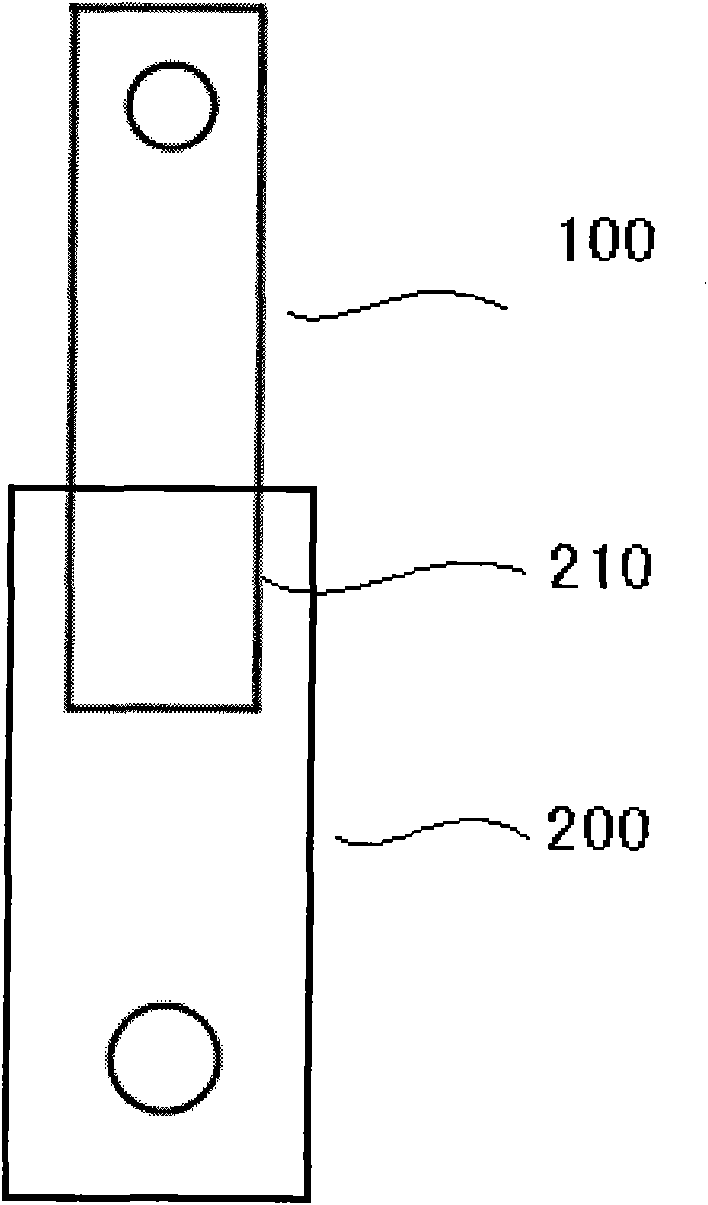

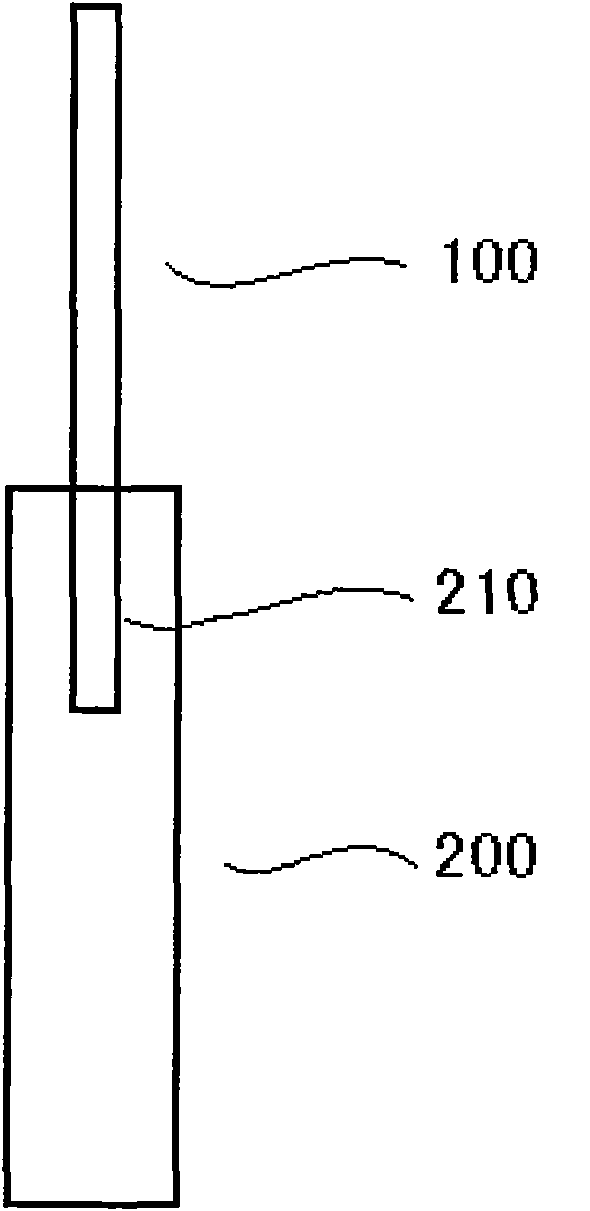

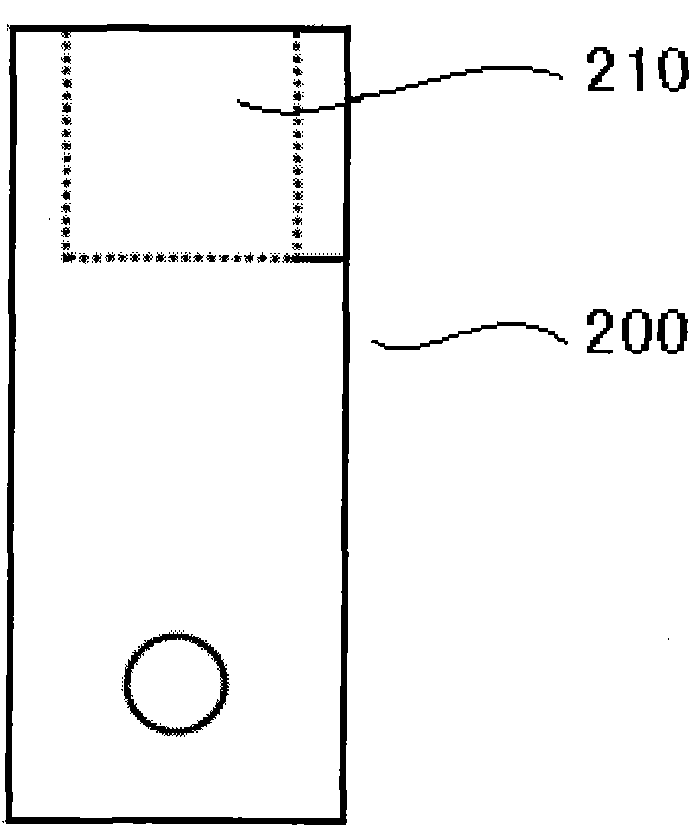

Image

Examples

Embodiment

[0048] Preparation:

[0049] Mix and grind polyester polyol resin or polyether polyol resin or polyaspartate resin with pigment (such as titanium dioxide), dispersant (such as organic phosphate, acrylate), solvent (such as propylene glycol methyl ether acetate) Prepared as a color paste. Combine solid additives with anti-icing properties, remaining polyol resins or polyaspartic ester resins, solvents (such as propylene glycol methyl ether acetate), catalysts (such as dibutylene dilaurate), additives, etc. at high speed (1750rpm) After dispersing for 20 minutes, slowly add to the color paste. Continue to disperse at high speed for 20 minutes to obtain component B of the coating.

[0050] The A component of the coating is in some cases purchased directly from the supplier, eg HDI trimer. Isocyanate derivatives and isocyanate prepolymers are self-synthesized. Synthetic method: put isocyanate, proportioned polyol and solvent into a reaction kettle, add 0.1% organotin catalyst ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com