Carbon nanotube grafted polyvinyl chloride composite material with self-cleaning, anti-icing, photo-thermal and deicing characteristics and preparation method thereof

A carbon nanotube and polyvinyl chloride technology, applied in chemical instruments and methods, other chemical processes, etc., to achieve the effects of low production cost, easy processing and molding, and low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Preparation of sodium carboxylated carbon nanotubes:

[0042] Using glassware as a reaction vessel, add a metered amount of virgin carbon nanotubes to a mixed acid of concentrated sulfuric acid and concentrated nitric acid to purify carboxylation under 500w ultrasound. The ultrasonic temperature is 30℃ and the ultrasonic time is 10h; the mixed acid and carbon nanotubes are separated by centrifugation Afterwards, the carbon nanotubes were washed with 95% ethanol for several times until the pH was 6.5-7.0; sodium hydroxide and deionized water were added to the obtained carboxylated carbon nanotubes, and the ultrasonic dispersion and sodiumization were continued. The ultrasonic power was 500w. The ultrasonic temperature is 30°C, and the ultrasonic time is 5 minutes; the carbon nanotubes obtained by centrifugation are washed with 95% ethanol until the pH is 7.0-7.5, dried at 110°C, and ground to obtain sodicated carboxylated carbon nanotubes;

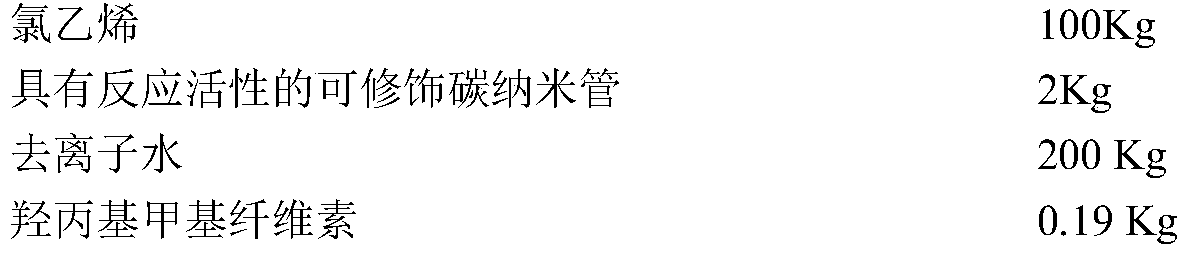

[0043] The dosage of each ingr...

Embodiment 2

[0055] (1) Preparation of sodium carboxylated carbon nanotubes:

[0056] Using glassware as the reaction vessel, add the metered raw carbon nanotubes to the mixed acid of concentrated sulfuric acid and concentrated nitric acid to purify the carboxylation under 2000w ultrasound, the ultrasonic temperature is 40℃, the ultrasonic time is 8h; the mixed acid and carbon nanotubes are separated by centrifugation Afterwards, the carbon nanotubes were washed with 95% ethanol for several times until the pH was 6.5-7.0; sodium hydroxide and deionized water were added to the obtained carboxylated carbon nanotubes, and the ultrasonic dispersion and sodiumization were continued, the ultrasonic power was 2000w, The ultrasonic temperature is 40°C, and the ultrasonic time is 2 minutes; the carbon nanotubes obtained by centrifugation are washed with 95% ethanol until the pH is 7.0-7.5, dried at 110°C, and ground to obtain sodiumized carboxylated carbon nanotubes;

[0057] The dosage of each ingredie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com