Method and device for detecting heat conductivity near melting point of phase change energy storage material

A phase change energy storage material and detection method technology, applied in the direction of material thermal development, etc., can solve problems such as difficulty in measuring heat flow, errors in thermal parameter values of phase change materials, and inability to measure thermal conductivity of viscous liquids and solids, etc., to ensure authenticity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Sodium nitrate test: In order to solve the error introduced by the difference between the experimental boundary conditions and the theoretical boundary conditions, this study introduces the "reverse-positive two-step calculation method". The first step is to obtain the "simple" experimental data of thermophysical properties according to the inverse problem of heat transfer and the analytical solution of the ideal model, and complete the experimental test part.

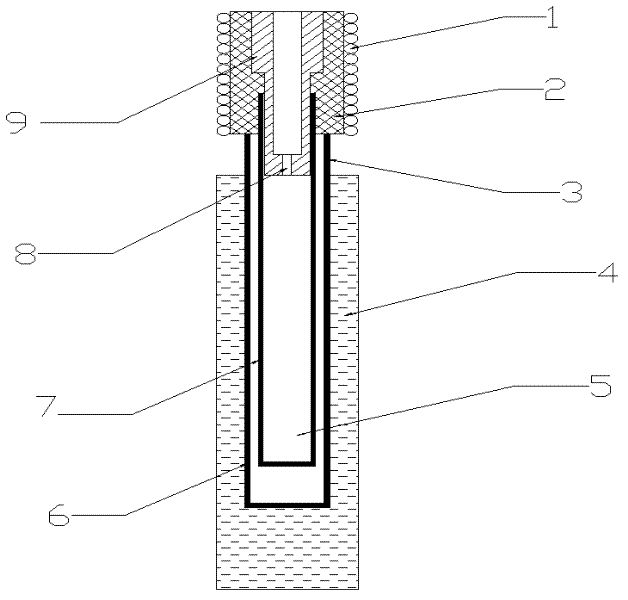

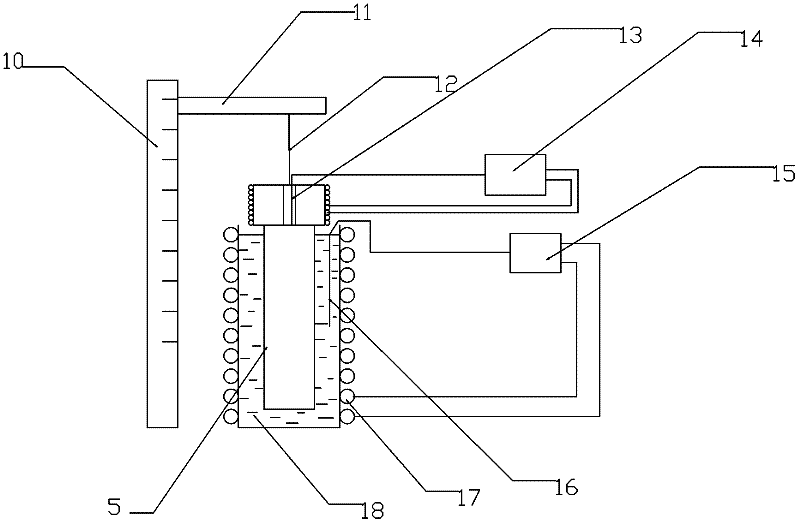

[0058] Experimental device such as figure 1 and figure 2 shown.

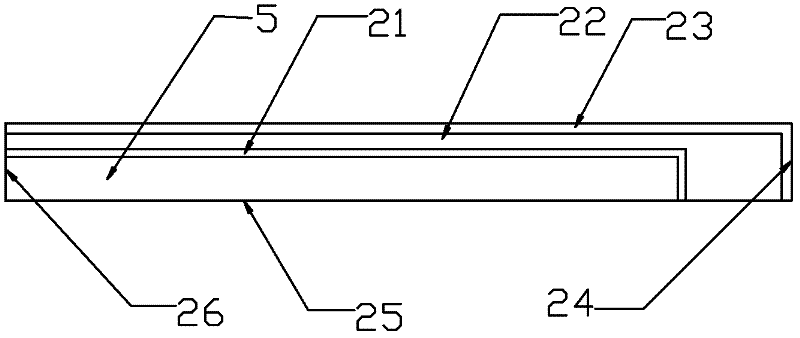

[0059] The sodium nitrate sample used in the test was analytically pure sodium nitrate produced by Tianjin Kemiou Chemical Reagent Co., Ltd., with a purity of ≥99.0% and a melting point of 307°C. The phase change chamber (double-layer quartz tube) is filled with solid sodium nitrate, and the sample is repeatedly melted and solidified to eliminate the holes in the solid sodium nitrate; before the test starts, the salt bath control system is conn...

Embodiment 2

[0070] Zinc bromide test: the sample is analytically pure zinc bromide produced by Tianjin Kemiou Chemical Reagent Co., Ltd., with a purity of ≥99.0% and a melting point of 394°C. Experimental device such as figure 1 and figure 2 shown.

[0071] In the first step, the phase change chamber (double-layer quartz tube) is filled with solid zinc bromide, and the sample is repeatedly melted and solidified to eliminate the holes in the solid zinc bromide; before the test starts, the salt bath control system is connected, and the temperature of the salt bath Maintain at 390°C, control the temperature of the iron block on the upper end surface at 390°C, and immerse the phase change chamber in a salt bath (pure lithium nitrate, salt bath range 280-500°C) until the temperature is stable; at t=0s, the iron block on the upper end face Suddenly raise the temperature to 474°C, the upper end of the molten salt to be tested begins to melt, and the phase interface gradually moves down; use t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com