Red light compensation fluorescent glass ceramic, preparation method thereof and application thereof in white light LED device

A fluorescent glass, red fluorescent technology, applied in glass manufacturing equipment, glass molding, semiconductor devices and other directions, to achieve the effects of good application prospects, low preparation cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

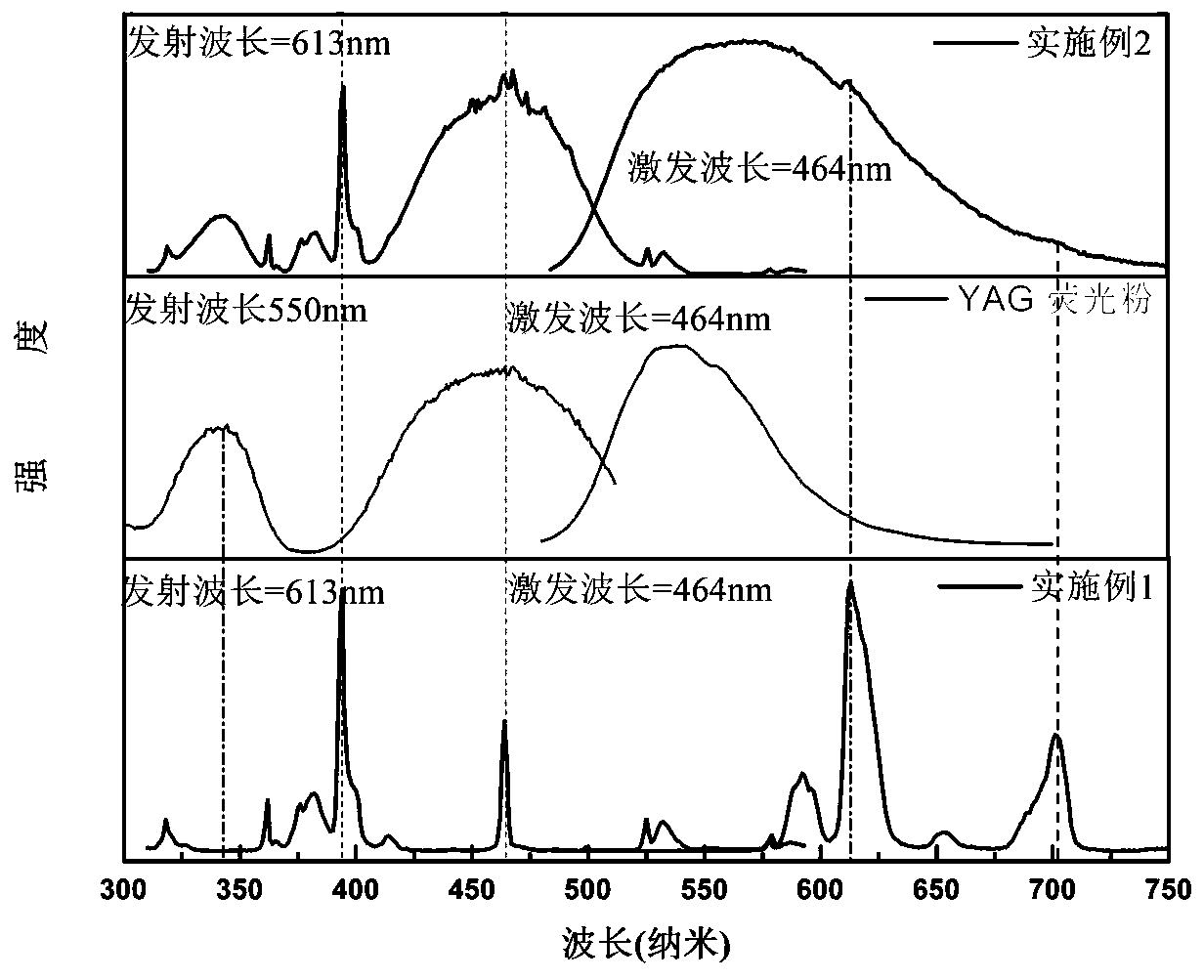

[0045] In this embodiment, a red light compensation fluorescent glass is mixed and sintered with phosphate red light glass powder to form a fluorescent glass material as an inorganic light conversion material. The red light compensation fluorescent glass can emit red light when excited by blue light . Phosphate red light glass is prepared by high temperature melting method. The composition and molar ratio of oxide components of the prepared phosphate red light glass are: Na 2 O, ZnO, P 2 o 5 , B 2 o 3 and Eu 2 o 3 The molar ratio of the glass is 18:42:28:10:2; through the low-temperature sintering method, red compensation fluorescent glass is made.

[0046] In this embodiment, a method for preparing red light compensation fluorescent glass ceramics of this embodiment includes the following steps:

[0047] a. Raw material preparation: according to Na 2 O, ZnO, P 2 o 5 , B 2 o 3 and Eu 2 o 3 Molar ratio of oxide components: Na 2 O, ZnO, P 2 o 5 , B 2 o 3 and E...

Embodiment 2

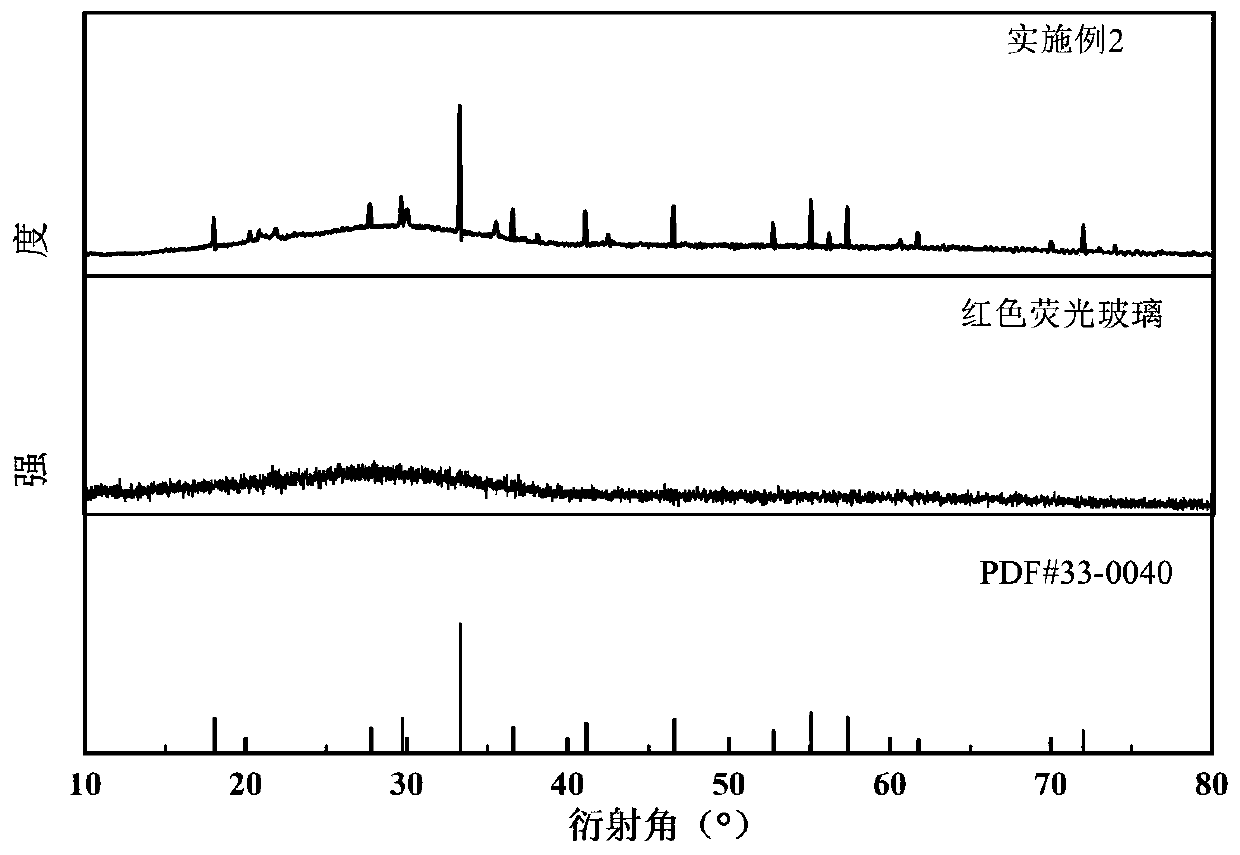

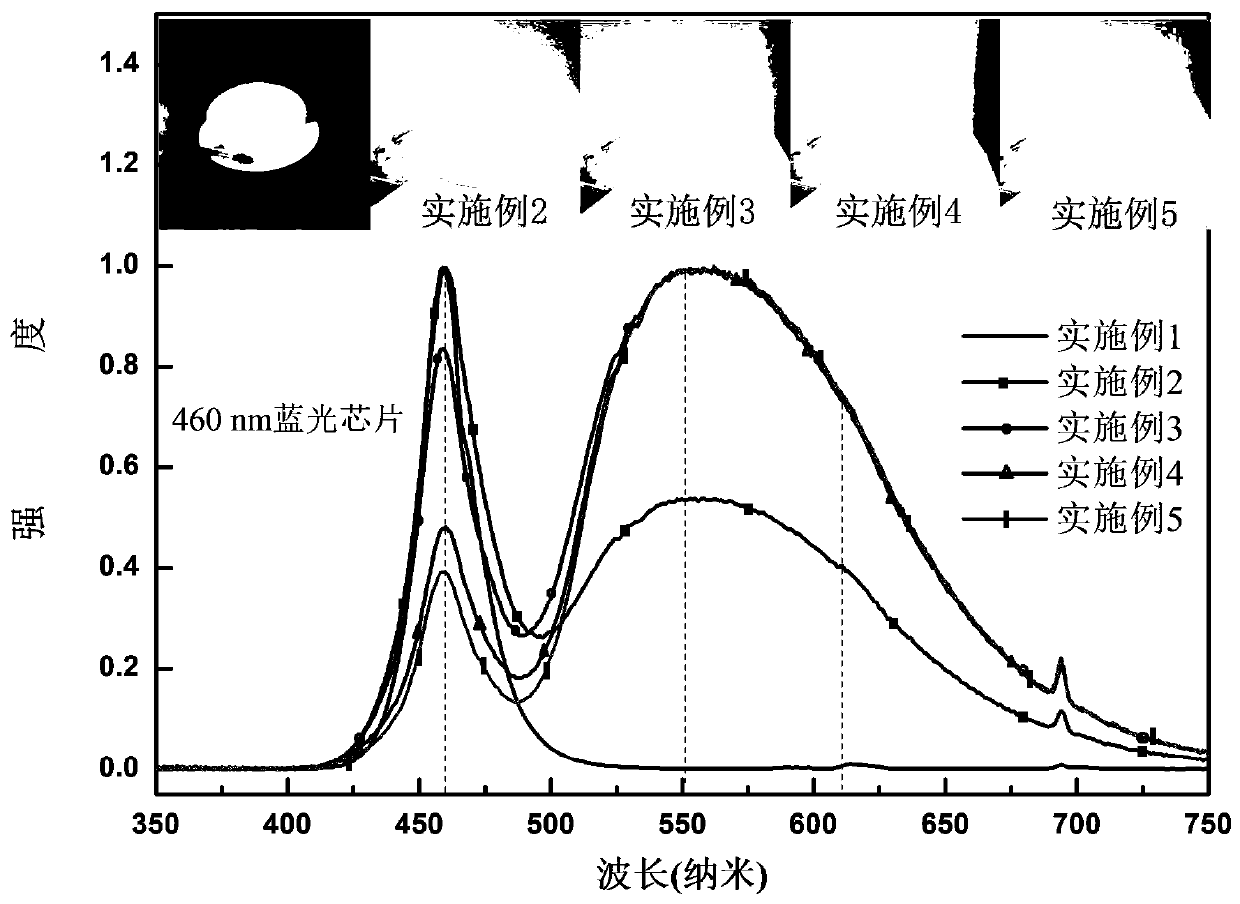

[0054] In this embodiment, a kind of red light compensation fluorescent glass ceramics is made of phosphate red light glass and YAG:Ce 3+ The yellow fluorescent powder is mixed and sintered to form a luminescent glass-ceramic composite material. As an inorganic light conversion material, the red-light-compensated fluorescent glass-ceramic can simultaneously emit red light and yellow light when excited by blue light. Phosphate red light glass is prepared by high temperature melting method. The composition and molar ratio of oxide components of the prepared phosphate red light glass are: Na 2 O, ZnO, P 2 o 5 , B 2 o 3 and Eu 2 o 3 The molar ratio of the phosphate glass is 18:42:28:10:2; the phosphate glass is doped with YAG:Ce by low temperature co-firing method 3+ Yellow phosphor to make red light compensation fluorescent glass ceramics. In this embodiment, red fluorescent glass is ground to obtain red fluorescent glass glass powder, and then the glass powder and YAG:Ce ...

Embodiment 3

[0066] This embodiment is basically the same as Embodiment 2, and the special features are:

[0067]In this embodiment, a kind of red light compensation fluorescent glass ceramics is made of phosphate red light glass and YAG:Ce 3+ The yellow fluorescent powder is mixed and sintered to form a luminescent glass-ceramic composite material. As an inorganic light conversion material, the red-light-compensated fluorescent glass-ceramic can simultaneously emit red light and yellow light when excited by blue light. Phosphate red light glass is prepared by high temperature melting method. The composition and molar ratio of oxide components of the prepared phosphate red light glass are: Na 2 O, ZnO, P 2 o 5 , B 2 o 3 and Eu 2 o 3 The molar ratio of the phosphate glass is 18:42:28:10:2; the phosphate glass is doped with YAG:Ce by low temperature co-firing method 3+ Yellow phosphor to make red light compensation fluorescent glass ceramics. In this embodiment, red fluorescent glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com