Nano-structure-controllable diluted magnetic semiconductor material and preparation method and device thereof

A technology of dilute magnetic semiconductors and nanostructures, applied in nanostructure applications, liquid injection devices, nanotechnology, etc., can solve problems such as high preparation costs, complex equipment, and low deposition efficiency, and achieve concentrated droplet size distribution and solve Effect of heat conduction damage and improvement of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

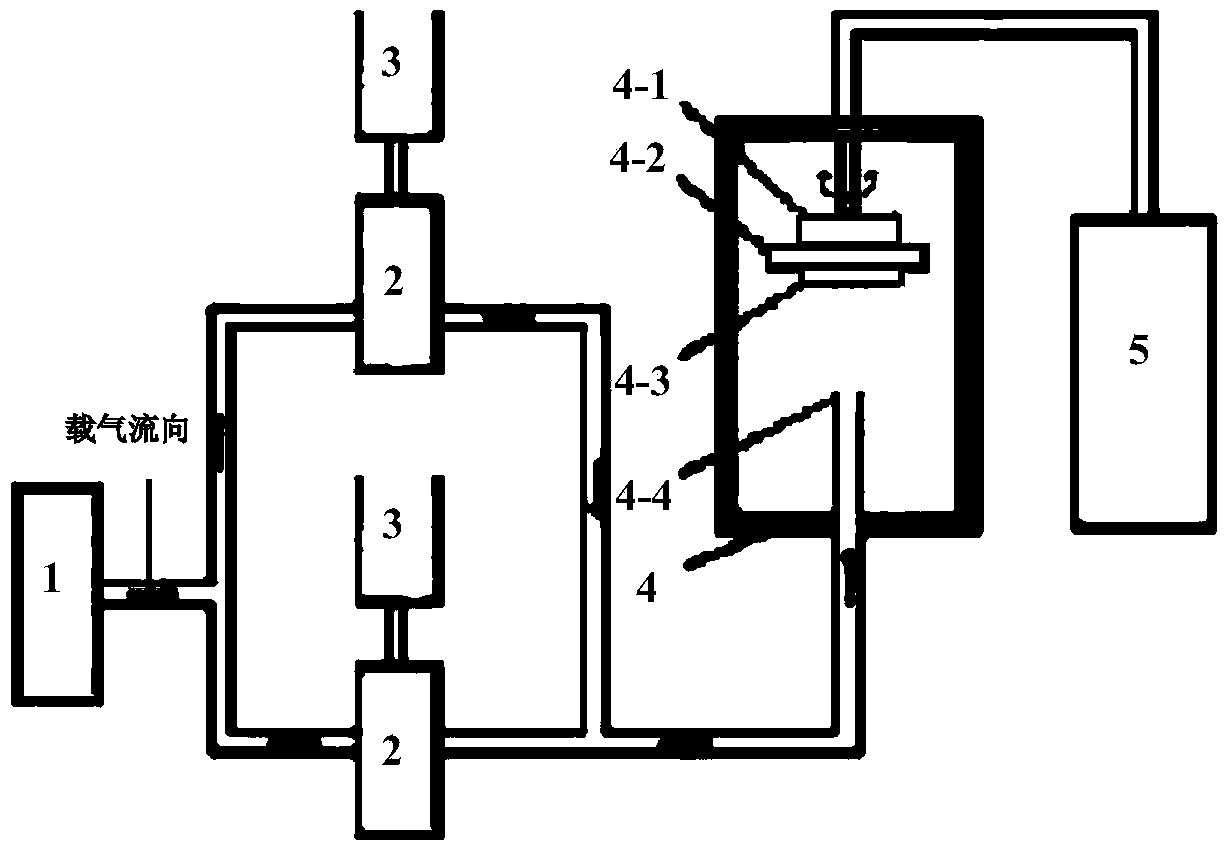

[0060] Dual-source ultrasonic atomization pyrolysis spraying improvement device of the present invention (see schematic diagram figure 1 ), comprising a carrier gas pump 1, an atomization chamber, a reaction chamber 4 and an electric control system 5 connected in sequence, the carrier gas pump, the atomization chamber and the reaction chamber are connected by a pipeline, and the reaction chamber and the electric control system are connected by a circuit; the atomization chamber is composed of Composed of two parallel atomization tanks 2, the atomization tanks 2 are respectively connected with liquid cups 3, the bottom of the atomization tank 2 is provided with a cooling water circulation device, the inner bottom of the atomization tank 2 is provided with an isolation film, and the liquid container A two-way variable-speed peristaltic pump is installed between the cup 3 and the atomizing tank 2, and the solution in the liquid-holding cup 3 is transported to the atomizing tank 2 ...

Embodiment 2

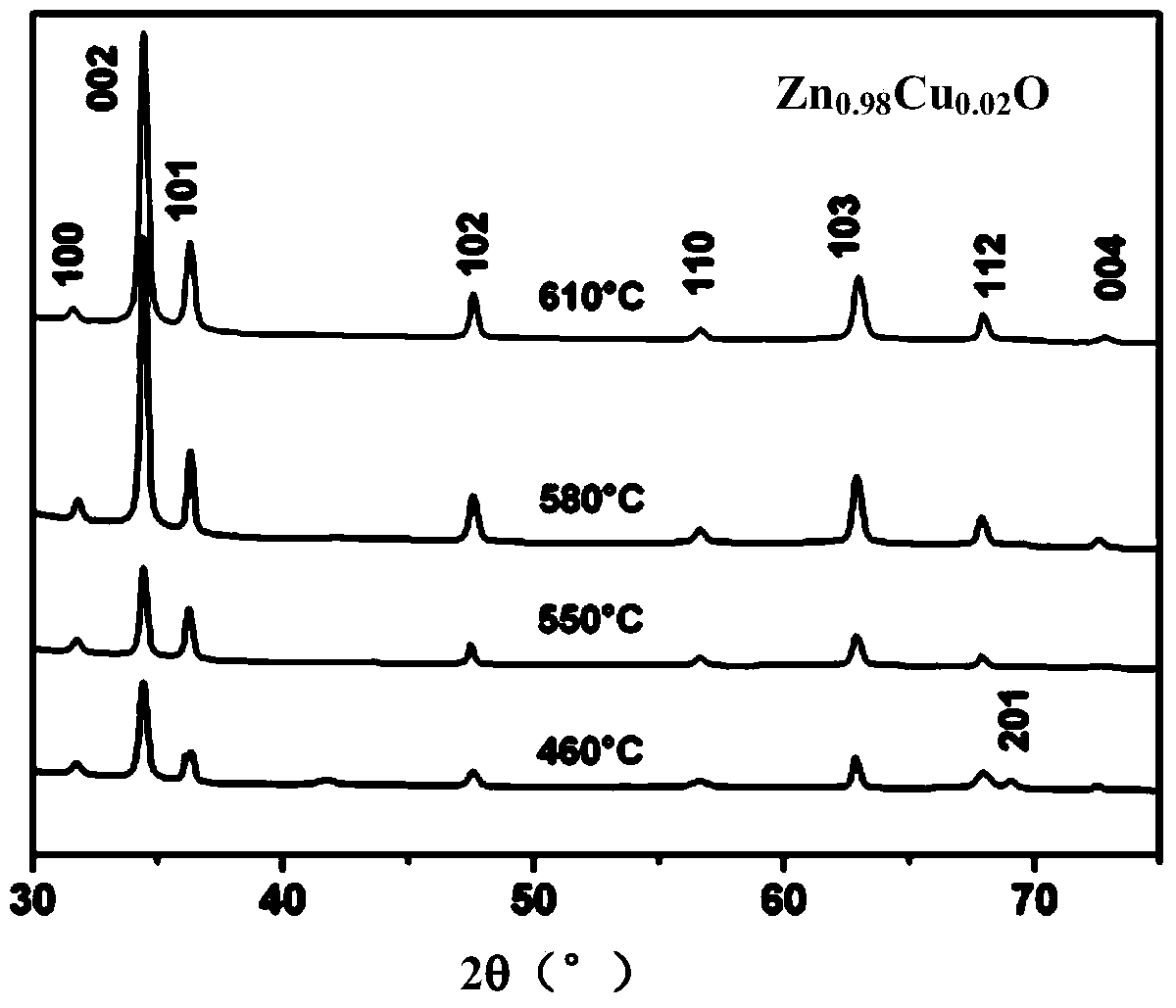

[0071] A common glass slide is used as the substrate, zinc acetate is selected as the source solution, and copper acetate is selected as the doping solution, and a dilute magnetic semiconductor with room temperature ferromagnetism and controllable nanostructure is prepared by using the improved dual-source ultrasonic atomization pyrolysis spraying device of the present invention. Materials, specific steps and parameters are as follows:

[0072] (1) First, according to the target product chemical formula Zn 0.98 Cu 0.02 O will 21.51g of Zn(CH 3 COO) 2 2H 2 O and 0.399g of Cu(CH 3 COO) 2 ·H 2 O powder is dissolved in the beaker that fills 500mL distilled water respectively, is configured into the zinc acetate solution that concentration is 0.2mol / L and the copper acetate solution of same volume with it;

[0073] (2) To prevent Zn(OH) 2 and Cu(OH) 2 For the formation of precipitates, add 2 to 3 drops of acetic acid to the prepared copper acetate and zinc acetate solution...

Embodiment 3

[0081] A common glass slide is used as the substrate, zinc acetate is selected as the source solution, and copper acetate is selected as the doping solution, and a dilute magnetic semiconductor with room temperature ferromagnetism and controllable nanostructure is prepared by using the improved dual-source ultrasonic atomization pyrolysis spraying device of the present invention. Materials, specific steps and parameters are as follows:

[0082] (1) First, according to the target product chemical formula Zn 0.98 Cu 0.02 O will 21.51g of Zn(CH 3 COO) 2 2H 2 O and 0.399g of Cu(CH 3 COO) 2 ·H 2 O powder is dissolved in the beaker that fills 500mL distilled water respectively, is configured into the zinc acetate solution that concentration is 0.2mol / L and the copper acetate solution of same volume with it;

[0083] (2) To prevent Zn(OH) 2 and Cu(OH) 2 For the formation of precipitates, add 2 to 3 drops of acetic acid to the prepared copper acetate and zinc acetate solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com