Carbon nanotube modified carbon fiber composite for automobile hubs and preparation method of composite

A carbon nanotube modification and carbon nanotube technology, which is applied in the field of carbon nanotube modified carbon fiber composite materials and their preparation, can solve the problems of weak mechanical properties, poor thermal conductivity and the like, so as to improve the interlaminar shear strength, Solve the effect of poor thermal conductivity and weak mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

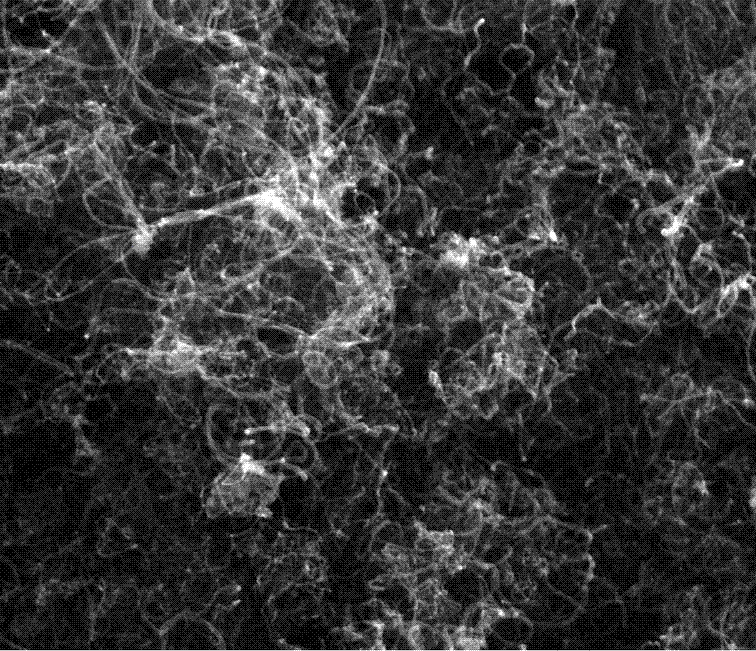

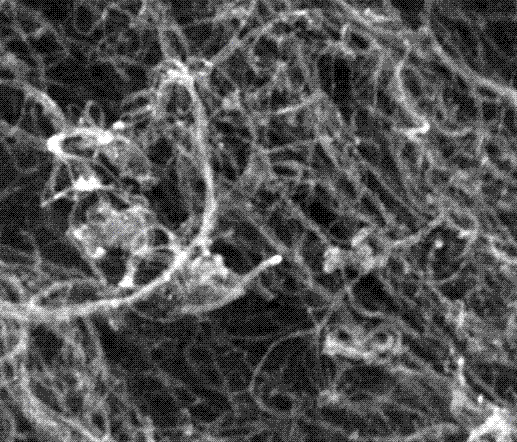

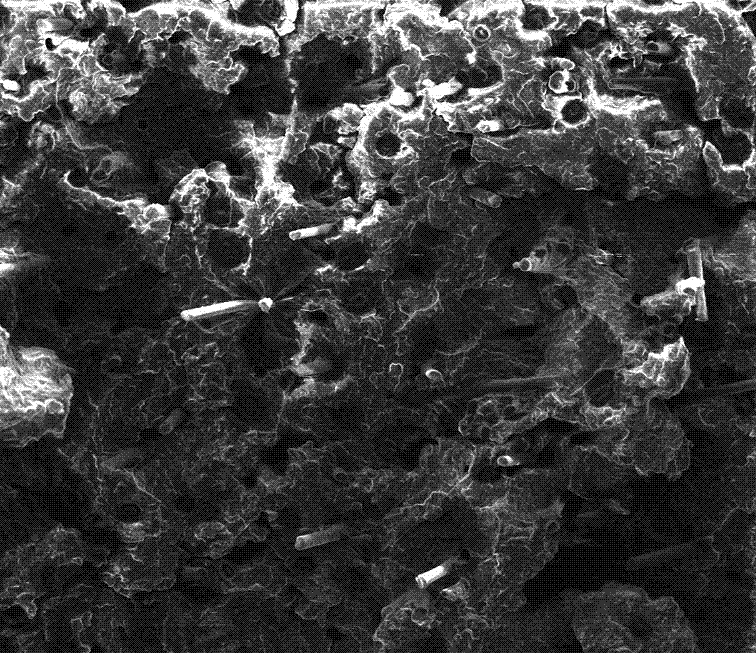

Image

Examples

Embodiment 1

[0038] A carbon nanotube modified carbon fiber composite material used for automobile hubs, comprising the following raw materials in parts by weight:

[0039] 75 parts of nylon PA66, 20 parts of carbon fiber, 2 parts of CNTs (CNTs-Ni) pretreated by nickel plating on the surface, 5 parts of toughening agent, 0.3 part of antioxidant, 0.5 part of lubricant, and 0.2 part of nucleating agent.

[0040] The preparation method of above-mentioned material comprises the following steps:

[0041] Step 1, take the following raw materials by weight, nylon PA66, carbon fiber, surface nickel-plated pretreated carbon nanotubes, toughening agent, antioxidant, lubricant, nucleating agent, remove carbon fiber, surface nickel-plated pretreated carbon nanotubes Add the raw materials other than the tube into the high-speed mixer, rotate at high speed for 5 minutes, mix well in advance, and prepare the premix;

[0042] Wherein, the preparation method of surface nickel-plated pretreatment carbon na...

Embodiment 2

[0051] A carbon nanotube modified carbon fiber composite material used for automobile hubs, comprising the following raw materials in parts by weight:

[0052] 75 parts of nylon PA66, 20 parts of carbon fiber, 3 parts of CNTs (CNTs-Ni) pretreated by nickel plating on the surface, 5 parts of toughening agent, 0.3 part of antioxidant, 0.5 part of lubricant, and 0.2 part of nucleating agent.

[0053] The preparation method of above-mentioned material comprises the following steps:

[0054] Step 1, take the following raw materials by weight, nylon PA66, carbon fiber, surface nickel-plated pretreated carbon nanotubes, toughening agent, antioxidant, lubricant, nucleating agent, remove carbon fiber, surface nickel-plated pretreated carbon nanotubes Add the raw materials other than the tube into the high-speed mixer, rotate at high speed for 5 minutes, mix well in advance, and prepare the premix;

[0055] Wherein, the preparation method of surface nickel-plated pretreatment carbon na...

Embodiment 3

[0064] A carbon nanotube modified carbon fiber composite material used for automobile hubs, comprising the following raw materials in parts by weight:

[0065] 75 parts of nylon PA66, 20 parts of carbon fiber, 5 parts of CNTs (CNTs-Ni) pretreated by nickel plating on the surface, 5 parts of toughening agent, 0.3 part of antioxidant, 0.5 part of lubricant, and 0.2 part of nucleating agent.

[0066] The preparation method of above-mentioned material comprises the following steps:

[0067] Step 1, take the following raw materials by weight, nylon PA66, carbon fiber, surface nickel-plated pretreated carbon nanotubes, toughening agent, antioxidant, lubricant, nucleating agent, remove carbon fiber, surface nickel-plated pretreated carbon nanotubes Add the raw materials other than the tube into the high-speed mixer, rotate at high speed for 5 minutes, mix well in advance, and prepare the premix;

[0068] Wherein, the preparation method of surface nickel-plated pretreatment carbon na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com