Combined polyether for continuous production of PIR block foam, as well as preparation method and application of combined polyether

A combination of polyether and bulk technology, applied in the field of polyurethane, can solve the problems of poor dimensional stability of foam, decrease of foam flame retardancy, high thermal conductivity, etc., and achieve the effect of stable foam quality, high compressive strength and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

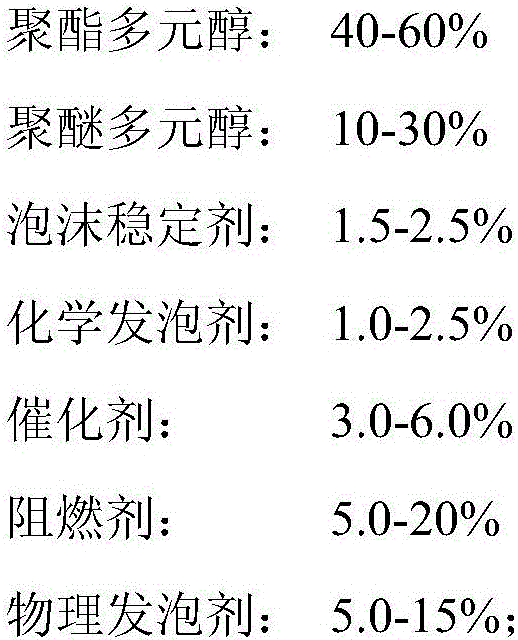

Method used

Image

Examples

Embodiment 1

[0043] To prepare 100 kg of component A, weigh the following raw materials:

[0044] Polyester polyol PE-B175: 50 kg, polyether polyol NJ-410HN: 20 kg, foam stabilizer L-5568: 2 kg, deionized water: 1.4 kg, PC8 (N,N-dimethylcyclohexyl Amine): 1 kg, JXP508: 1.4 kg, JXP509: 0.8 kg, TMR-35: 1.4 kg, FR606: 11 kg, CP: 11 kg.

[0045] Put PE-B175 and NJ-410HN into the reaction kettle, add L-5568, deionized water, PC8, JXP508, JXP509, TMR-35, FR606, CP, stir at room temperature for 1 hour, take it out for inspection, and meet the settings Foaming parameters, that is, the qualified product of component A, is taken out from the reaction kettle and put into barrels for storage.

[0046] Mix components A and B according to the weight ratio of A:B=100:170, and mix them evenly through foaming equipment to make a high-density PIR material for cold-keeping pipe support. The test product indicators are as follows:

[0047] Overall density: 43kg / cm 3

[0048] Thermal conductivity: 0.0231W / ...

Embodiment 2

[0056] To prepare 100 kg of component A, weigh the following raw materials:

[0057] Polyester polyol PE-B175: 60 kg, polyether polyol NJ-410HN: 10 kg, foam stabilizer L-5568: 2.0 kg, deionized water: 1.5 kg, PC8 (N,N-dimethylcyclohexyl Amine): 1.5 kg, JXP508: 1.4 kg, JXP509: 0.8 kg, TMR-35: 1.4 kg, FR606: 11 kg, CP: 10.4 kg.

[0058]Put PE-B175 and NJ-410HN into the reaction kettle, add L-5568, deionized water, PC8, JXP508, JXP509, TMR-35, FR606, CP, stir at room temperature for 1 hour, take it out for inspection, and meet the settings Foaming parameters, that is, the qualified product of component A, is taken out from the reaction kettle and put into barrels for storage.

[0059] Mix components A and B according to the weight ratio of A:B=100:170, and mix them evenly through foaming equipment to make a PIR type thermal insulation material for deep cooling. The test product indicators are as follows:

[0060] Overall density: 42.8kg / cm 3

[0061] Thermal conductivity: 0.0...

Embodiment 3

[0069] To prepare 100 kg of component A, weigh the following raw materials:

[0070] Polyester polyol PE-B175: 45 kg, polyether polyol NJ-410HN: 20 kg, foam stabilizer L-5568: 2.0 kg, deionized water: 1.5 kg, PC8 (N,N-dimethylcyclohexyl Amine): 1.2 kg, JXP508: 1.5 kg, JXP509: 0.8 kg, TMR-35: 1.5 kg, FR606: 14.5 kg, CP: 12 kg.

[0071] Put PE-B175 and NJ-410HN into the reaction kettle, add L-5568, deionized water, PC8, JXP508, JXP509, TMR-35, FR606, CP, stir at room temperature for 1 hour, take it out for inspection, and meet the settings Foaming parameters, that is, the qualified product of component A, is taken out from the reaction kettle and put into barrels for storage.

[0072] Mix components A and B according to the weight ratio of A:B=100:175, and mix them evenly through foaming equipment to make a PIR type thermal insulation material for deep cooling. The test product indicators are as follows:

[0073] Overall density: 42.6kg / cm 3

[0074] Thermal conductivity: 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com