Synthesis of p-phenyl unsaturated polyester resin by using waste polyester material

A polyester resin and unsaturated technology, which is applied in the field of synthesizing p-phenylene unsaturated polyester resin, can solve problems such as poor solubility, achieve good heat resistance, reduce product cost, and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

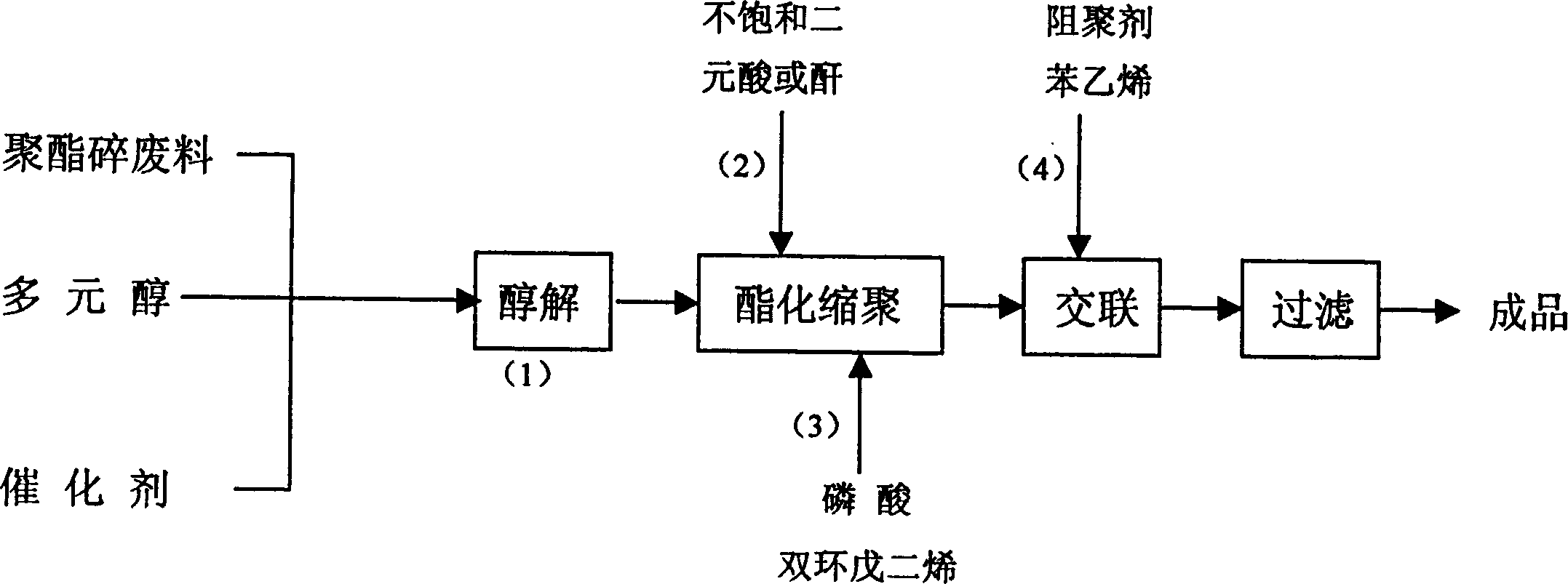

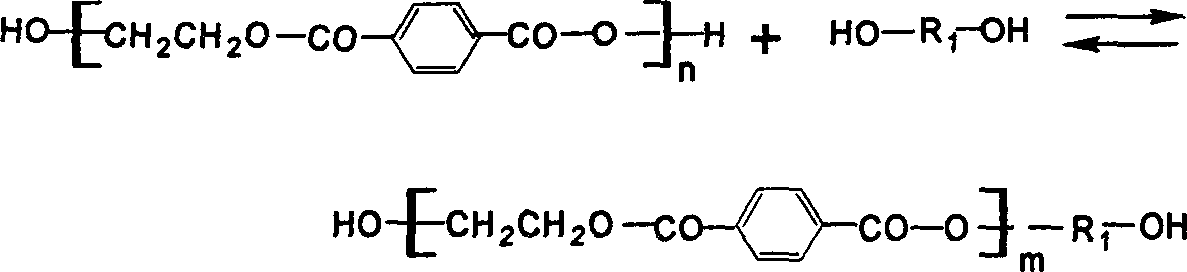

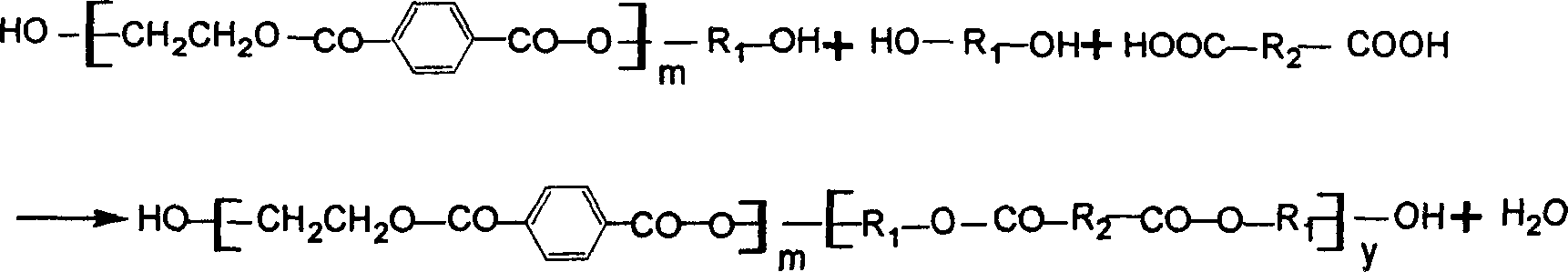

Method used

Image

Examples

Embodiment 1

[0044]In a four-neck flask with a thermometer, a stirrer, a nitrogen inlet tube and a fractionation device, 152 g of propylene glycol, 53 g of diethylene glycol, 96 g of PET polyester bottle fragments (about 5 mm in particle size), and 0.5 g of catalyst were successively added. g. The temperature is gradually raised to 190-200°C under the condition of feeding nitrogen, and the temperature of the fractionation column is lower than 105°C. Keep this temperature until all the polyester waste particles disappear. When the reaction system becomes gradually uniform and transparent, it is the end point of alcoholysis. Lower the temperature of the material to below 160°C and add 222g of maleic anhydride, gradually raise the temperature to 190-210°C, keep the temperature of the fractionation column lower than 105°C until the acid value reaches 80mgKOH / g, reduce the temperature of the material to 110-140°C and add 0.2g of phosphoric acid catalyst, slowly add 30g of dicyclopentadiene (DCP...

Embodiment 2

[0046] With 62g ethylene glycol, 76g propylene glycol, 53g diethylene glycol, 8g cyclohexanol, 96g oil-free polyester waste silk, 0.3g esterification catalyst manganese acetate drops in the four-necked flask shown in embodiment 1, subsequent steps In embodiment 1, maleic anhydride is changed into fumaric acid 262g, phosphoric acid is changed into 0.15g, dicyclopentadiene (DCPD) is changed into 25g, carries out by the same operating procedure as embodiment 1.

Embodiment 3

[0048] The 1500L reactor is equipped with a stirrer, a temperature display, a fractionating column and a feeding port. First, 228kg of propylene glycol and 79.5kg of diethylene glycol are pumped into the reactor. Heat the liquid components to about 100°C, start the mixer to feed nitrogen, add 144kg of PET polyester bottle fragments (particle size is about 5mm), and 2kg of stannous octoate as the esterification catalyst, close the feeding port after the feeding, continue to stir and heat up . When the still temperature rises to 170°C, there will be distillate, control the fractionation column temperature to be lower than 105°C, and record the reaction temperature and distillation head temperature every half hour during the reaction. Continue to raise the temperature to 190-200°C, and keep this temperature until all the polyester waste particles disappear. After 5-6 hours, when the reaction system becomes gradually uniform and transparent, it is the end point of alcoholysis. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com