Ester interchange method for producing bio-diesel oil

A technology for transesterification and biodiesel, which is applied in the preparation of biological raw materials, biofuels, and liquid hydrocarbon mixtures, etc., can solve the problems of difficult recovery of esterification products, high catalyst price, and short catalyst life, so as to reduce production costs and reduce costs. Equipment investment, enhanced microscopic mass transfer effect, and the effect of avoiding catalyst separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

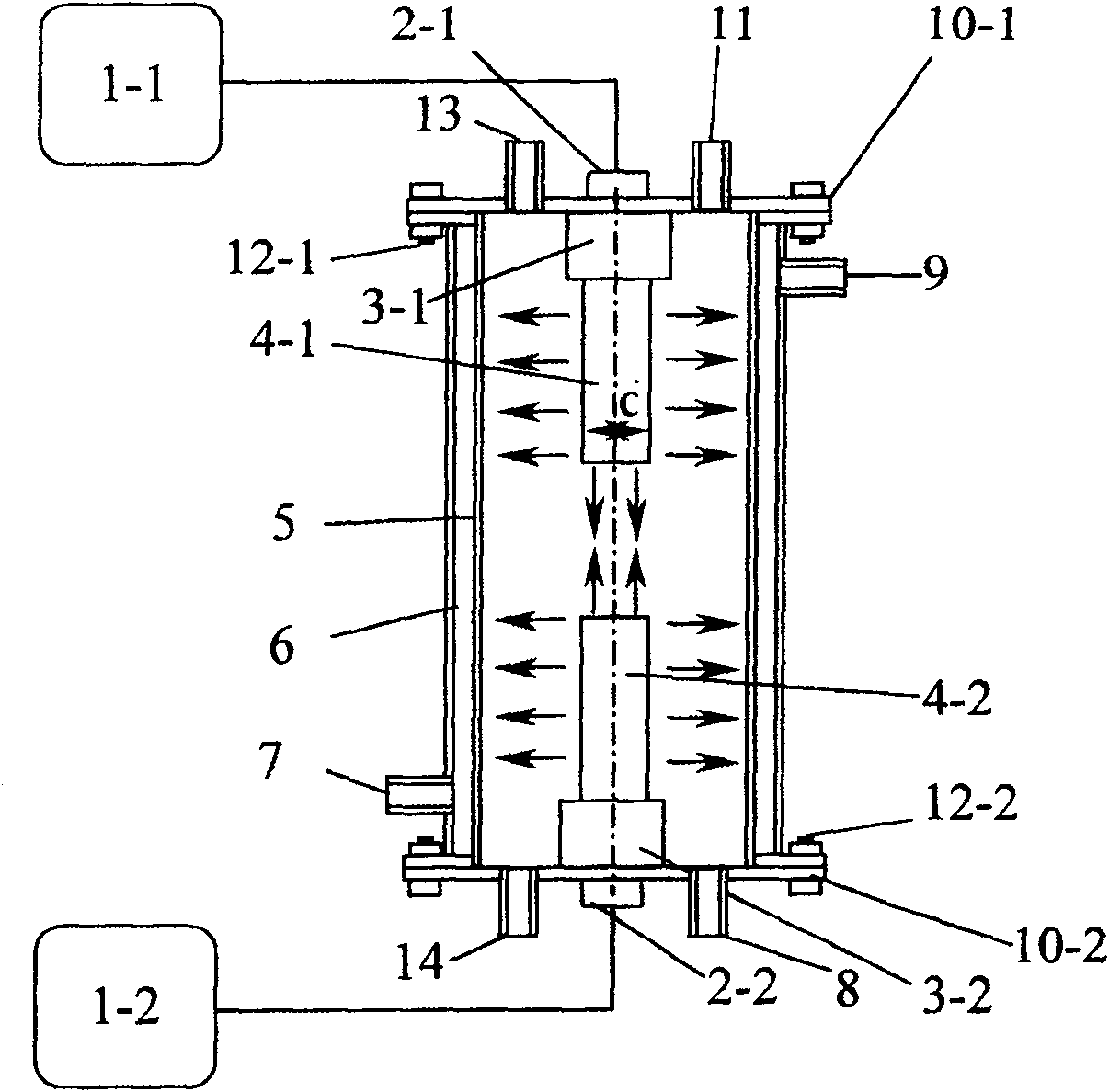

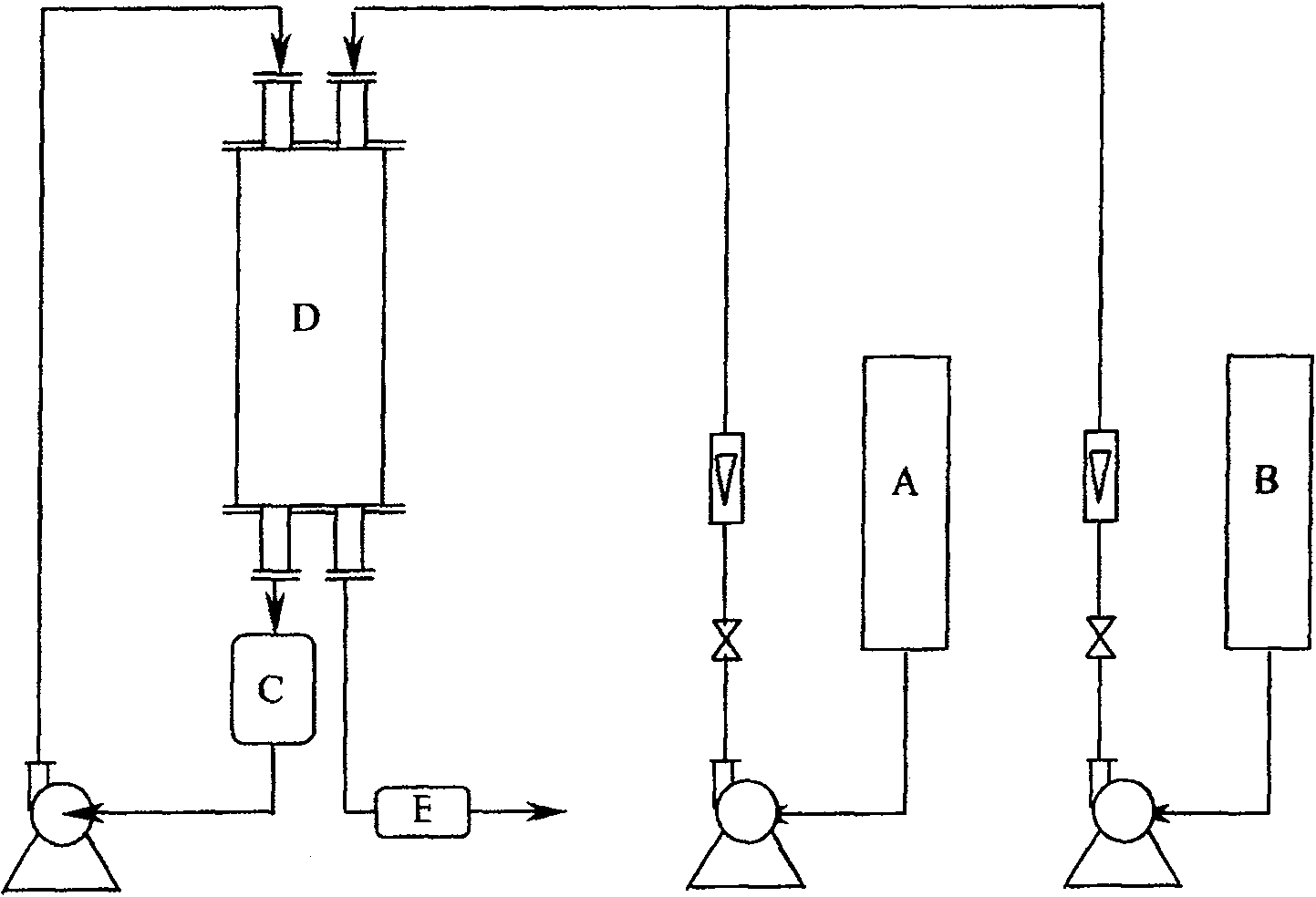

[0031] Add cottonseed oil in metering tank A, add methanol in metering tank B, the mol ratio of methanol and cottonseed oil is 10, the feed rate of cottonseed oil and methanol is equal to the effective volume of the transesterification reactor (that is, the feed volume space velocity is 1h -1 , that is, the reaction time is 1h), cottonseed oil and methanol are pumped into the transesterification reactor respectively, and the transesterification reaction is rapidly mixed with the circulating material in the transesterification reactor under the effect of ultrasonic waves, and the rate of the circulating material is 300% of the feed amount. Control the reaction temperature to 130° C., the reaction pressure to 0.8 MPa, the ultrasonic frequency to 15 kHz, and the power to 400 W / L of reaction material (the amount of reaction material is calculated according to the effective volume of the reactor, the same below). The reaction product flowing out from the discharge port of the tran...

Embodiment 2

[0033] According to the method of embodiment 1, just feed rate is 1 / 2nd of transesterification reactor effective volume, and circulating material rate is 400% of feed amount, and the frequency of ultrasonic wave is 30kHz, and power is 100W / L material. The reaction product flowing out from the reactor discharge port is separated by standing to obtain the fatty acid ester phase (upper layer). Utilizing the GC-14B gas chromatograph analysis of Daojin Company, the conversion rate of fatty acid triglyceride is 100%, and the fat The content of methyl ester in the ester phase is 92.8%.

Embodiment 3

[0035] According to the method of embodiment 1, the feed rate is 1 / 4 of the effective volume of the reactor, the circulating material rate is 200% of the feed amount, the frequency of the ultrasonic wave is 200kHz, and the power is 80W / L material. The reaction product flowing out from the discharge port of the transesterification reactor is separated by standing to obtain the fatty acid ester phase (upper layer), which is analyzed by the GC-14B gas chromatograph of Daojin Company, and the conversion rate of fatty acid triglyceride is 100%. , the content of methyl ester in the fatty acid ester phase is 89.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com