Environmental-friendly trace cutting fluid and preparation method thereof

A cutting fluid and trace technology, applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of processing places and environmental pollution, large amount of lubricants, waste of resources, etc., and achieve excellent performance. Compressive and anti-wear properties, good extreme pressure and anti-wear properties, and the effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Put 900g of ricinoleic acid and 100g of potassium tetraborate into a stirrer, and stir and react at a temperature of 100°C for 4 hours to form castor oil borate potassium salt, which is used as a trace cutting fluid precursor.

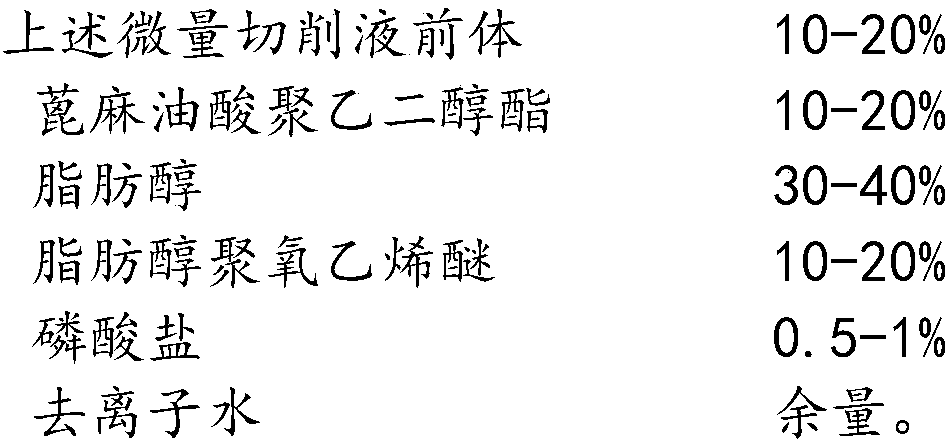

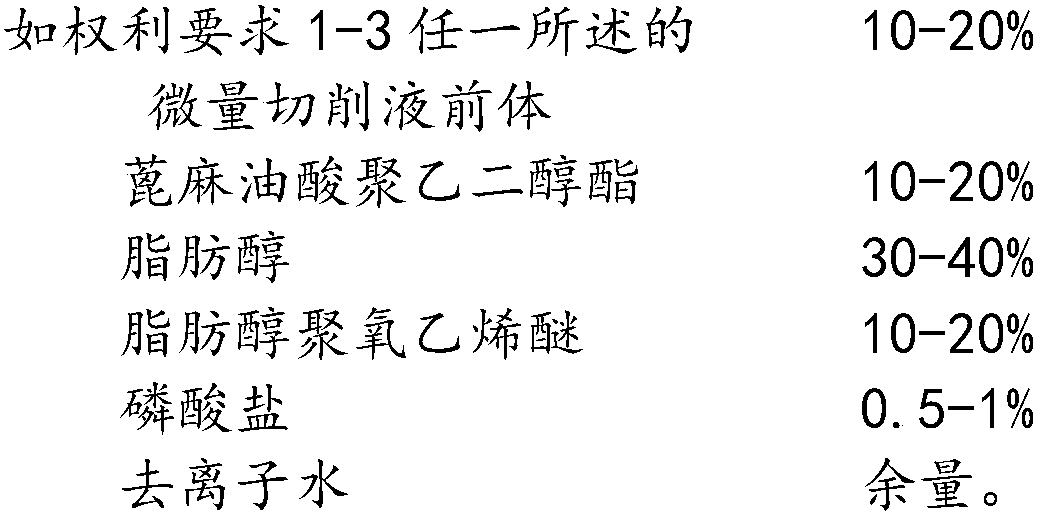

[0038] Take by weighing above-mentioned trace lubricating oil precursor 150g, polyethylene glycol ricinoleate 150g, oleyl alcohol 350g, fatty alcohol polyoxyethylene ether (AEO-9) 150g, 200g dipotassium hydrogen phosphate solution (10g dipotassium hydrogen phosphate Dissolve in 190g deionized water in advance) and mix and stir at 50°C until it becomes transparent, it becomes a kind of micro-cutting fluid.

[0039] The preparation method of above-mentioned Polyethylene Glycol Ricinoleate is:

[0040] Step 1: 500g ricinoleic acid, 750g polyethylene glycol (PEG-400) and catalyst (4g sodium perborate) are dropped into the polymerization kettle respectively;

[0041] Step 2: Filling with nitrogen to replace the air in the polymerization kettle;

[...

Embodiment 2

[0047] Put 950g of ricinoleic acid and 50g of sodium borate into a stirrer, and stir and react at a temperature of 110°C for 3 hours to form castor oil borate sodium salt, which is used as a trace cutting fluid precursor.

[0048] Take by weighing 200g of the above-mentioned trace lubricating oil precursor, 200g of polyethylene glycol ricinoleate, SAFOL16 isomeric alcohol (produced by Sasol, the main component is C16 isomeric alcohol) 300g, fatty alcohol polyoxyethylene ether (AEO-10 ) 200g, 100g potassium phosphate solution (dissolve 5g potassium phosphate in 95g deionized water in advance) and mix and stir at 60°C until it becomes transparent, it is a kind of trace cutting fluid.

[0049] The preparation method of above-mentioned Polyethylene Glycol Ricinoleate is:

[0050] Step 1: 500g ricinoleic acid, 1000g polyethylene glycol (PEG-600) and catalyst are dropped into the polymerization kettle respectively;

[0051] Step 2: Filling with nitrogen to replace the air in the po...

Embodiment 3

[0055] Put 920g of ricinoleic acid and 80g of potassium metaborate into a stirrer, and stir and react at a temperature of 90°C for 4 hours to form castor oil borate potassium salt, which is used as a trace cutting fluid precursor.

[0056] Weigh 100g of the above-mentioned trace lubricating oil precursor, 100g of polyethylene glycol ricinoleate, ISALCHEM145 isomer alcohol (produced by Sasol, the main component is C14 / 15 isomer alcohol) 400g, fatty alcohol polyoxyethylene ether (AEO -15) 150g, 250g of potassium dihydrogen phosphate solution (dissolve 8g of potassium dihydrogen phosphate in 242g of deionized water in advance) and mix and stir at 50°C until it becomes transparent, then it becomes a trace cutting fluid.

[0057] The preparation method of above-mentioned Polyethylene Glycol Ricinoleate is:

[0058] Step 1: 500g ricinoleic acid, 500g polyethylene glycol (PEG-200) and catalyst (3g potassium perborate) are dropped into the polymerization kettle respectively;

[0059]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com