Lubricating mechanism of vehicle transmission case

A technology for automotive gearboxes and lubricating mechanisms, applied in the direction of gear lubrication/cooling, etc., can solve problems such as complex and difficult mechanisms, and achieve the effects of improving service life, solving dead zones or difficult lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

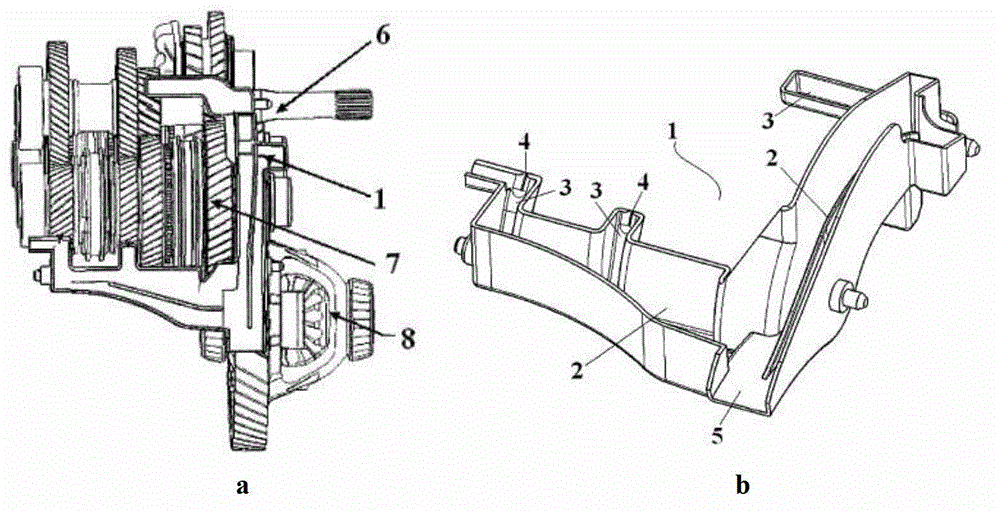

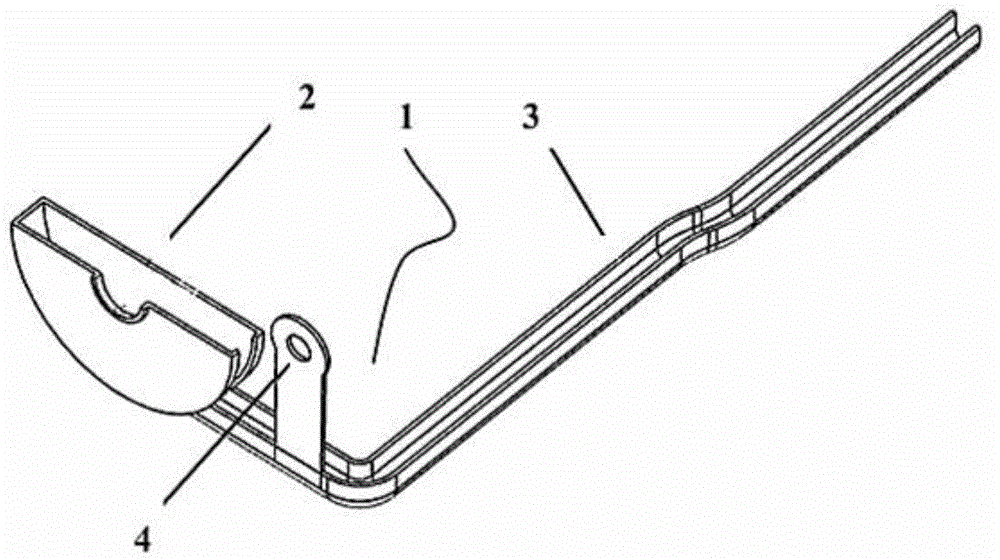

[0021] like figure 2 and Figure 7 As shown, this embodiment includes: a gearbox oil guide plate 1, which is arranged in the transmission and connected to the rear case of the gearbox, and a mounting hole 4 for installing and fixing the oil guide plate 1 is designed in the rear case of the gearbox , the oil guide plate 1 is fixed in the gearbox by these mounting holes 4 . The oil deflecting plate 1 includes an oil collection groove 2 and an oil delivery groove 3, wherein the oil delivery groove 3 not only plays the role of oil delivery, but also has the function of oil collection.

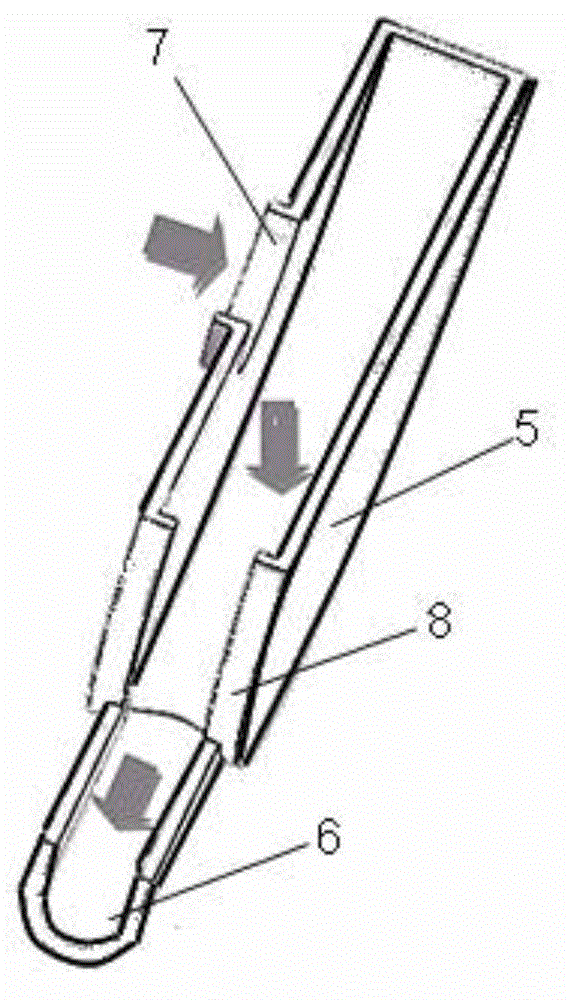

[0022] like image 3 As shown, the oil sump 2 is composed of an open cavity 5 of a semicircular structure and an open output conduit 6, wherein: the inlet 7 of the oil sump is arranged at the center of the semicircular structure of the open cavity 5, The open output conduit 6 is arranged on one side of the open cavity 5, and a rib 8 is provided on the edge of the open cavity corresponding to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com