Synthetic lubricating oil composition for air compressor and preparation method thereof

A lubricating oil composition and technology for air compressors, applied in the field of lubricating grease, can solve the problems of no coke cleaning function, poor lubrication of the compressor, unstable working state, etc., and achieve excellent coke cleaning function and good anti-coking function. performance, the effect of solving poor lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention also provides a kind of preparation method of synthetic air compressor lubricating oil composition, comprises the following steps:

[0054] Weigh the following raw materials:

[0055] 0.1wt%~10wt% tackifier;

[0056] 2wt%~7wt% antioxidant;

[0057] 0.05wt%~1wt% anti-corrosion agent;

[0058] 1wt%~8wt% extreme pressure antiwear agent;

[0059] 0.0001wt%~0.05wt% defoamer;

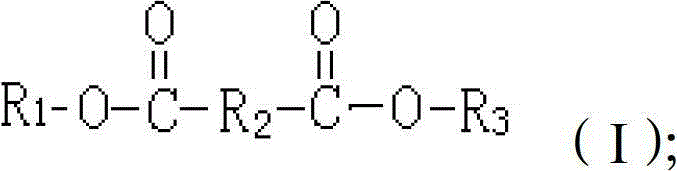

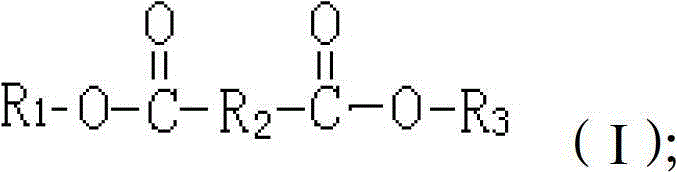

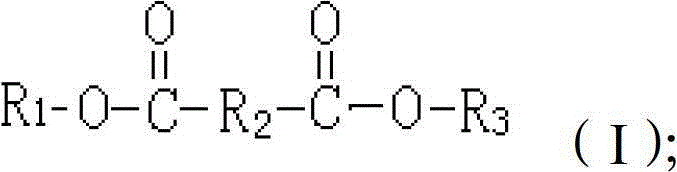

[0060] The rest of the ester oil, the ester oil has a formula (I) structure:

[0061]

[0062] Among them, R 1 , R 3 Independently selected from alkyl groups with 5 to 20 carbon atoms, R 2 selected from alkylene groups with 5 to 18 carbon atoms;

[0063] The raw materials were mixed to obtain a synthetic air compressor lubricating oil composition.

[0064] According to the above mass percentages, the present invention weighs each raw material respectively, stirs and mixes them, and obtains a synthetic air compressor lubricating oil composition. Each raw material is co...

Embodiment 1

[0073] Put 89.9kg of ester oil with the structure of formula (I) in a vacuum conditioning kettle, heat up to 85°C, add 0.18kg of tackifier, 3kg of IRGANOX L01 antioxidant, 0.4kg of IRGANOXL06 antioxidant, 0.5kg of T706 corrosion inhibitor, 6kg of Melt tricresyl phosphate (TCP) and 0.02kg of 901 defoamer and pump it into the kettle, and continue to heat up to 100°C to obtain a lubricating oil mixture;

[0074] Under a vacuum of 0.09 MPa, the lubricating oil mixture was stirred and dehydrated for 1 hour, cooled to 50° C., and filtered with diatomaceous earth to obtain a synthetic air compressor lubricating oil composition.

[0075] According to the method described above, the synthetic air compressor lubricating oil composition is subjected to a performance test, and the test results are shown in Table 1, and Table 1 shows the performance of the synthetic air compressor lubricating oil composition obtained in Examples 1 to 3 of the present invention .

Embodiment 2

[0077] Put 86.097kg of ester oil with the structure of formula (I) in a vacuum conditioning kettle, raise the temperature to 85°C, add 5.4kg of tackifier, 3kg of 2,6-di-tert-butyl-α-dimethylamino-p-cresol, 0.5kg tolutriazole, 5kg dibutyl phosphite and 0.003kg No. 10000 methyl silicone oil are melted and pumped into the kettle, and continue to heat up to 110°C to obtain a lubricating oil mixture;

[0078] Under a vacuum of 0.09 MPa, the lubricating oil mixture was stirred and dehydrated for 1 hour, cooled to 50° C., and filtered with diatomaceous earth to obtain a synthetic air compressor lubricating oil composition.

[0079] The performance test of the synthetic air compressor lubricating oil composition was carried out according to the method described above, and the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com