Self-lubricating method of textured coating of gear cold extrusion die

A cold extrusion and texturing technology, which is applied in metal extrusion forming tools, coatings, metal extrusion, etc., can solve the problems of environmental pollution, mold wear, poor lubrication effect of cold extrusion molds, etc., and achieve improved Anti-wear and anti-friction performance, prolong service life and improve lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Self-lubrication of textured coating based on gear cold extrusion die surface

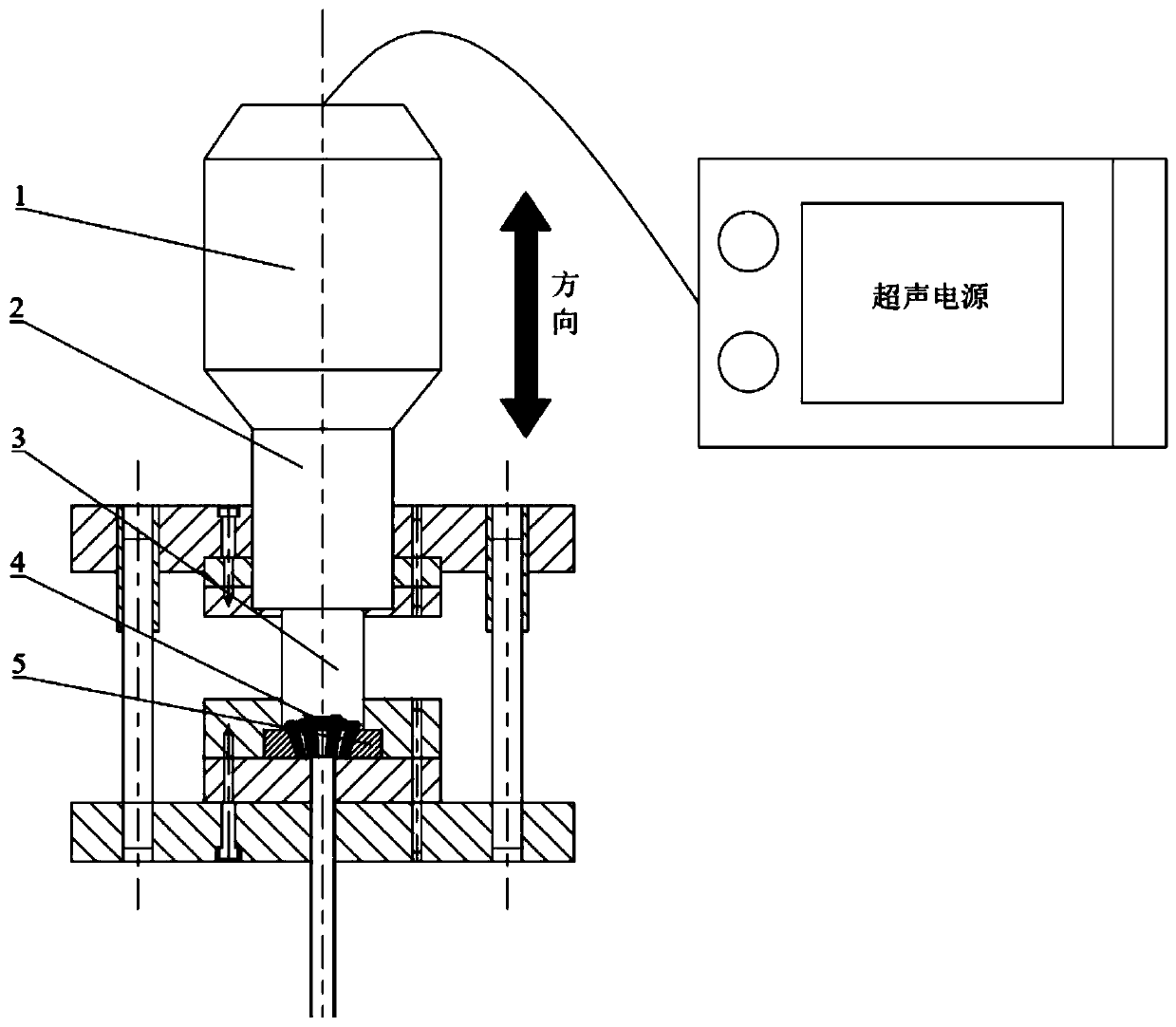

[0041] Equipment used: Swiss PLATITπ300 nanocomposite coating equipment, Nd:YAG laser, PG-2 floor metallographic polishing machine, KYX25-2400L ultrasonic cleaning machine, Ohaus Discovery measuring and analyzing balance, ultrasonic filling and pressing device.

[0042] A method for self-lubricating a textured coating of a gear cold extrusion die, comprising the following steps:

[0043] Step 1: Deposit TiAlN Coating

[0044] First, ultrasonically clean the inner ring 5 of the cold extrusion die for 15 minutes, then put the inner ring 5 of the die into the vacuum furnace cavity of the Swiss PLATIT π300 nanocomposite coating equipment, turn on the mechanical pump, and stabilize the pressure of the furnace cavity at 5×10 -3 Pa, the concave mold 5 is radiated and heated by a heater and stabilized at 450° C., the rotation speed of the built-in fixture in the furnace cavity is set to 3 r / min, an...

Embodiment 2

[0052] A method for self-lubricating a textured coating of a gear cold extrusion die, comprising the following steps:

[0053] Step 1: Deposit TiAlN Coating

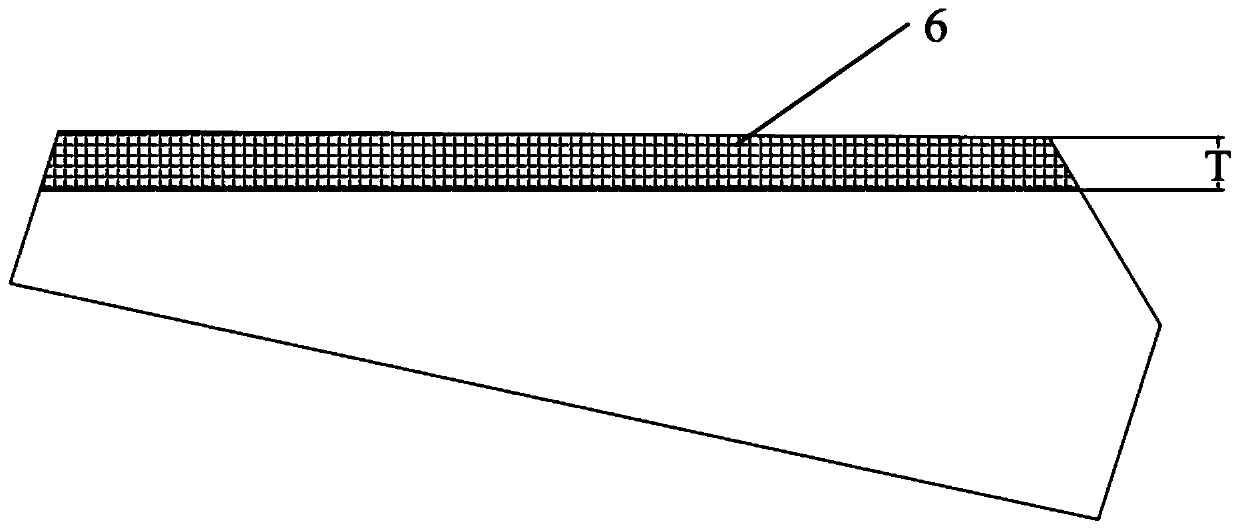

[0054] First, ultrasonically clean the inner ring 15 of the cold extrusion die for 15 minutes, then put the inner ring 15 of the die into the vacuum furnace cavity of the Swiss PLATIT π300 nanocomposite coating equipment, turn on the mechanical pump, and stabilize the pressure of the furnace cavity at 5×10 -3 Pa, the concave mold 15 is radiated and heated by a heater and stabilized at 450° C., the rotating speed of the fixture built in the furnace cavity is set to 3 r / min, and the concave mold 15 is plasma cleaned for 16 minutes in an argon atmosphere. Using Si target and AlTi (67% Ti, 33% Al) alloy target as the arc source, the deposition time is 150min, and a TiAlN coating 6 with a thickness T of 4 μm is obtained, as figure 1 shown.

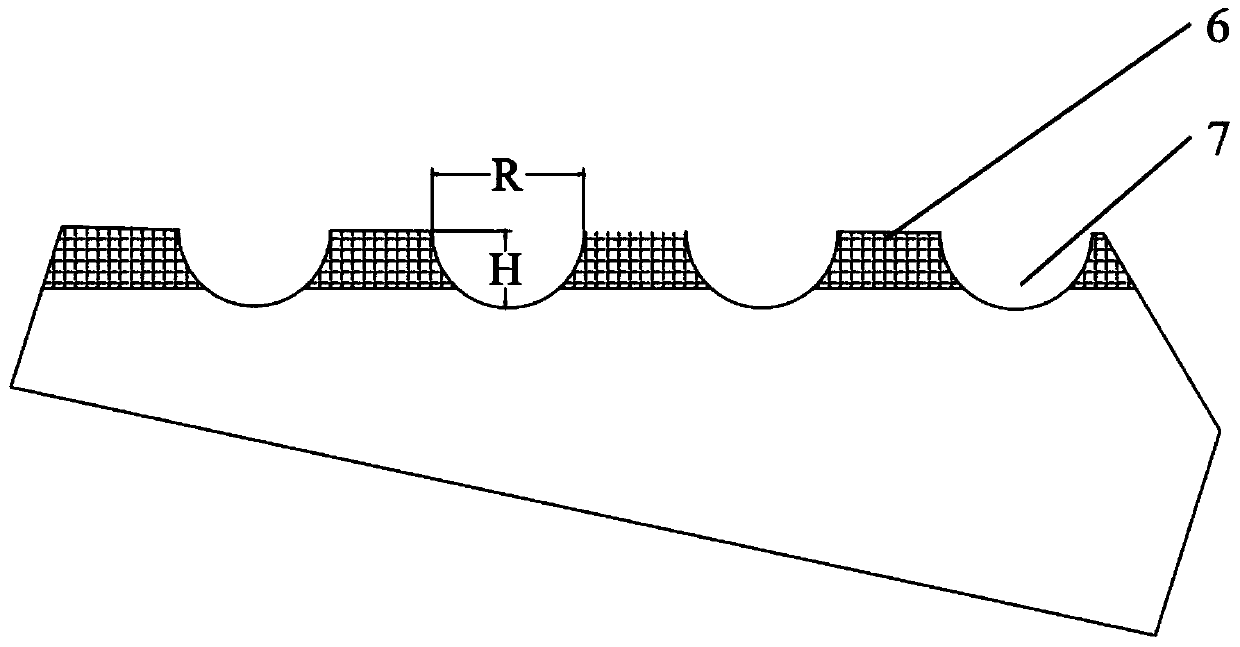

[0055] Step 2: Surface micro-modelling

[0056] Utilize two-stage pumping Nd:YAG l...

Embodiment 3

[0062] A method for self-lubricating a textured coating of a gear cold extrusion die, comprising the following steps:

[0063] Step 1: Deposit TiCN coating

[0064] First, ultrasonically clean the inner ring 5 of the cold extrusion die for 15 minutes, then put the inner ring 5 of the die into the vacuum furnace cavity of the Swiss PLATIT π300 nanocomposite coating equipment, turn on the mechanical pump, and stabilize the pressure of the furnace cavity at 5×10 -3 Pa, the concave mold 5 is radiated and heated by a heater and stabilized at 450° C., the rotation speed of the built-in fixture in the furnace cavity is set to 3 r / min, and the concave mold 5 is plasma cleaned for 16 minutes in an argon atmosphere. Using Si target and Ti target as the arc source, the deposition time is 150 min, and the TiCN coating 6 with a thickness T of 3 μm is obtained, as figure 1 shown.

[0065] Step 2: Surface micro-modeling

[0066] Utilize two-stage pumping Nd:YAG laser to carry out micromod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com