Preparation method of modified polysaccharides lubrication collapse inhibitor

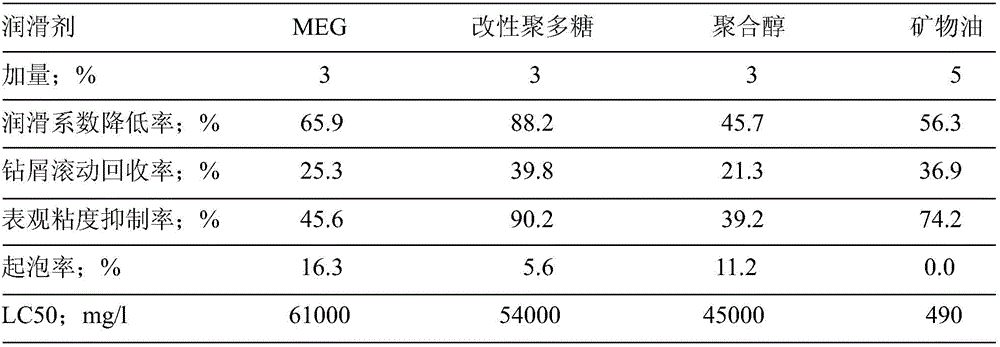

A technology of polysaccharides and inhibitors, which is applied in the field of preparation of cationic alkyl glycosides, can solve the problems of weak anti-slump inhibition and poor lubricity, achieve stable product quality, reduce energy consumption, and improve product lubricity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

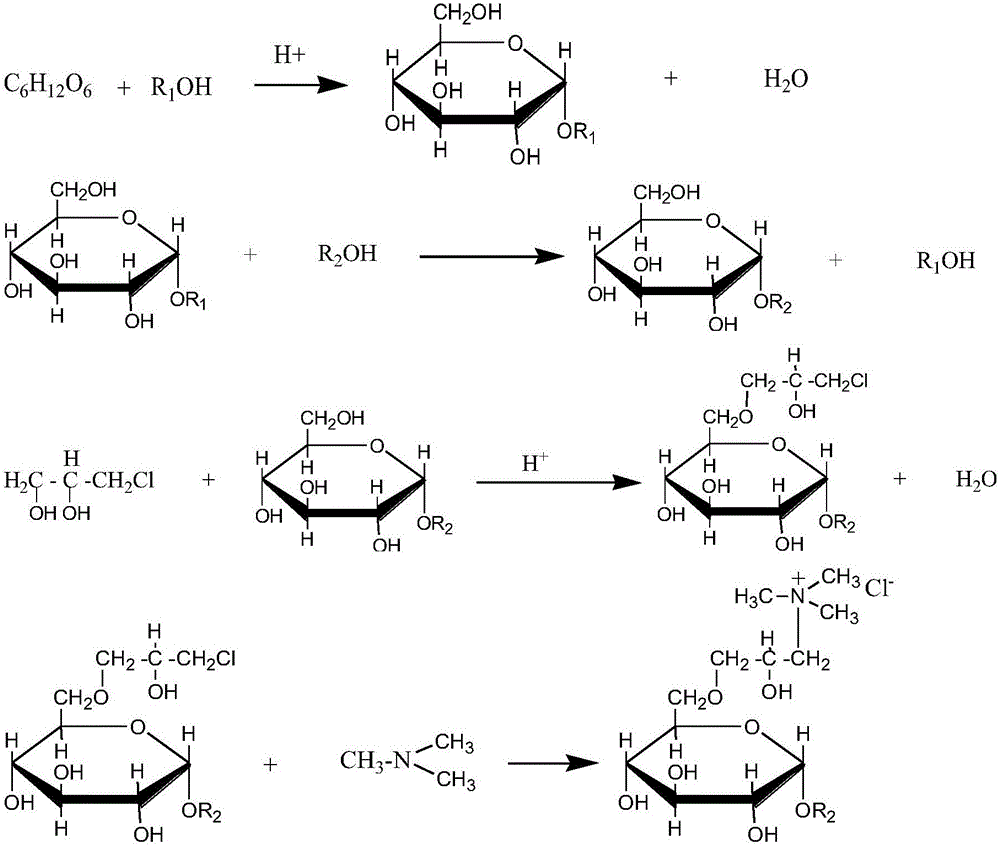

Method used

Image

Examples

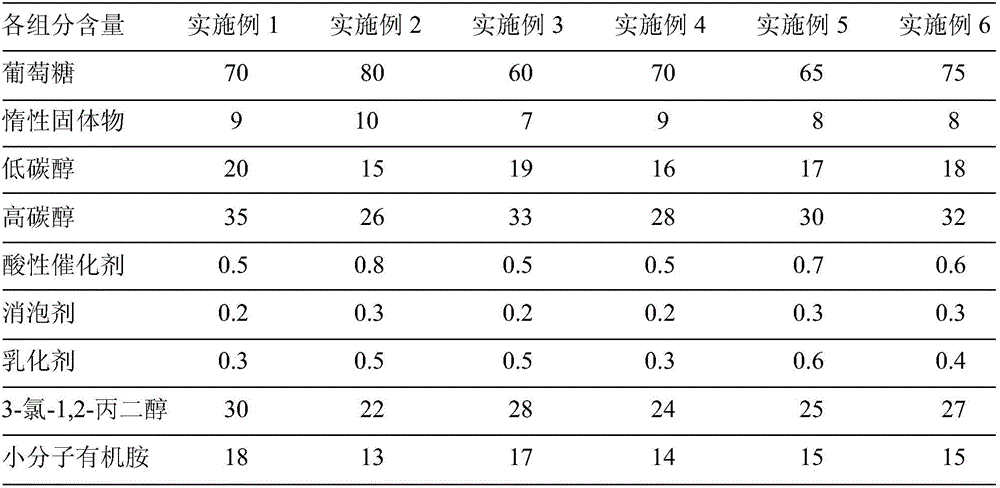

Embodiment 1

[0032]1) Take 70g of glucose and add it to the reactor, start the reactor agitator to stir; 2) Slowly add 9g of 400 mesh quartz sand to the reactor while stirring; 3) Then add 0.5g of alkylbenzene Sulfonic acid and 20g of butanol were kneaded at 80°C for 4 hours, vacuumed to 0.08KPa, and unreacted low-carbon alcohols and moisture were drawn out; 4) Add 35g of octanol to the reactor and add while stirring. Add 0.5g of alkylbenzenesulfonic acid, 0.2g of defoamer emulsified silicone oil, and 0.3g of emulsifier OP-10 intermittently while stirring, and mix them uniformly, then raise the temperature to above 90°C, and control the reaction temperature at 90°C ℃-100℃, the reaction time is 4h, the vacuum degree is 0.09KPa, and the water and butanol are filtered out under reduced pressure, and the butanol is collected in a special container; 5) Add 30g of 3-chloro-1,2 -Propylene glycol, the reaction temperature is 90°C, the reaction time is 5h, the water vapor is filtered out under redu...

Embodiment 2

[0034] Each component of the added raw material is as described in Table 1, and its specific steps are: 1) get 80g of glucose and add in the reactor, start the reactor agitator to stir; 2) slowly stir while stirring the 400 mesh quartz sand of 10g Add it into the reactor for mixing and stirring; 3) Then add 0.8g sulfuric acid and 15g ethanol, knead and react at a temperature of 80°C for 4h, vacuumize to 0.08KPa, and extract unreacted ethanol and moisture; 4) Add to the reaction Add 26g of decanol into the container, add while stirring, and also intermittently add 0.8g of sulfuric acid, 0.3g of defoamer polyoxyethylene polyoxypropanolamine ether and 0.5g of emulsifier OP-7 while stirring, and mix them After uniformity, raise the temperature to above 90°C, and control the reaction temperature at 100°C, the reaction time is 4h, the vacuum degree is 0.09KPa, and the moisture and ethanol are filtered out under reduced pressure, and the ethanol is collected in a special container; 5)...

Embodiment 3

[0036] Each component of the added raw material is described in Table 1, and its specific steps are: 1) get 60g of glucose and add in the reactor, start the reactor stirrer to stir; 2) slowly stir while stirring the 400 mesh quartz sand of 7g again Add to the reactor for mixing and stirring; 3) Then add 0.5g of p-toluenesulfonic acid and 19g of ethylene glycol, knead and react at a temperature of 80°C for 4 hours, vacuumize to 0.08KPa, and draw out unreacted ethylene glycol and water ; 4) add 33g lauryl alcohol to reactor again, add while stirring, also add 0.5g p-toluenesulfonic acid, 0.2g antifoaming agent polydimethylsiloxane and 0.5g emulsifying simultaneously while stirring OP-10, the defoamer and emulsifier are commonly used products on the market. After mixing them evenly, the temperature is raised to above 90°C, and the reaction temperature is controlled at 95°C. The reaction time is 4h, and the vacuum degree is 0.09 Filter out the water and ethylene glycol under reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com