Preparation method of Ni-Al based low friction and abrasion resistant composite material

A composite material and low-friction technology, applied in the field of high-temperature lubricating materials, can solve the problems of complex composition and process, and achieve good lubricating performance in a wide temperature range, improved high-temperature self-lubricating range, and good lubricating performance in a wide temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The components and their mass percentages of Ni-Al-based wide temperature range high temperature low friction and antiwear composites are: Ni: 58.2%, Al: 26.8%, Ag 3 VO 4 : 15%. First, the nickel and aluminum powders with a purity greater than 99.0% were mixed according to the mass ratio of Ni: 58.2% and Al: 26.8% (Ni-50at.%Al at this time), and the above mixture was placed in a four-tank planetary high-energy ball mill (FRITSCH, Germany) The wet ball milling process is used for ball milling. The ball milling time is 70h, the speed is 250r / min, and the ball-to-material ratio is 10:1. Then silver vanadate (Ag 3 VO 4 ) powder by Ag 3 VO 4 : 15% mass ratio is added to the above-mentioned mixture, and then the above-mentioned mixture is ball-milled by the above-mentioned wet ball milling process for 5 hours, and after drying, the mixed powder is obtained. Weigh the above mixed powder and put it into a graphite mold for cold-pressing pre-forming, the pre-forming pressu...

Embodiment 2

[0024] The components and their mass percentages of the Ni-Al-based wide temperature range high temperature, low friction and wear resistant composites are: Ni: 61.7%, Al: 28.3%, Ag 3 VO 4 : 10%. First, the nickel and aluminum powders with a purity greater than 99.0% were mixed according to the mass ratio of Ni: 61.7%, Al: 28.3% (Ni-50at.%Al at this time), and the above mixture was placed in a four-tank planetary high-energy ball mill (FRITSCH, Germany) The wet ball milling process is used for ball milling. The ball milling time is 70h, the speed is 250r / min, and the ball-to-material ratio is 10:1. Then silver vanadate (Ag 3 VO 4 ) powder by Ag 3 VO4 : 10% mass ratio is added to the above-mentioned mixture, and then the above-mentioned mixture is ball-milled by the above-mentioned wet ball milling process for 5 hours, and after drying, the mixed powder is obtained. Weigh the above mixed powder and put it into a graphite mold for cold-pressing pre-forming, the pre-forming ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

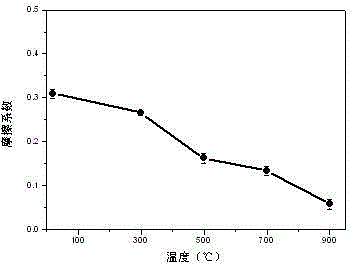

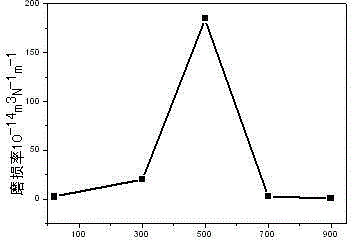

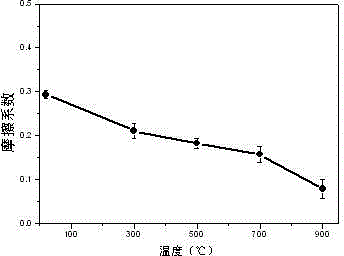

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com