Reciprocating type friction wear testing machine with lubricating and complex force loading system

A friction and wear test, loading system technology, applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve the problems of simulation of lubrication and wear, small load, inability to simulate friction conditions, etc., and achieve the effect of solving lubrication difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

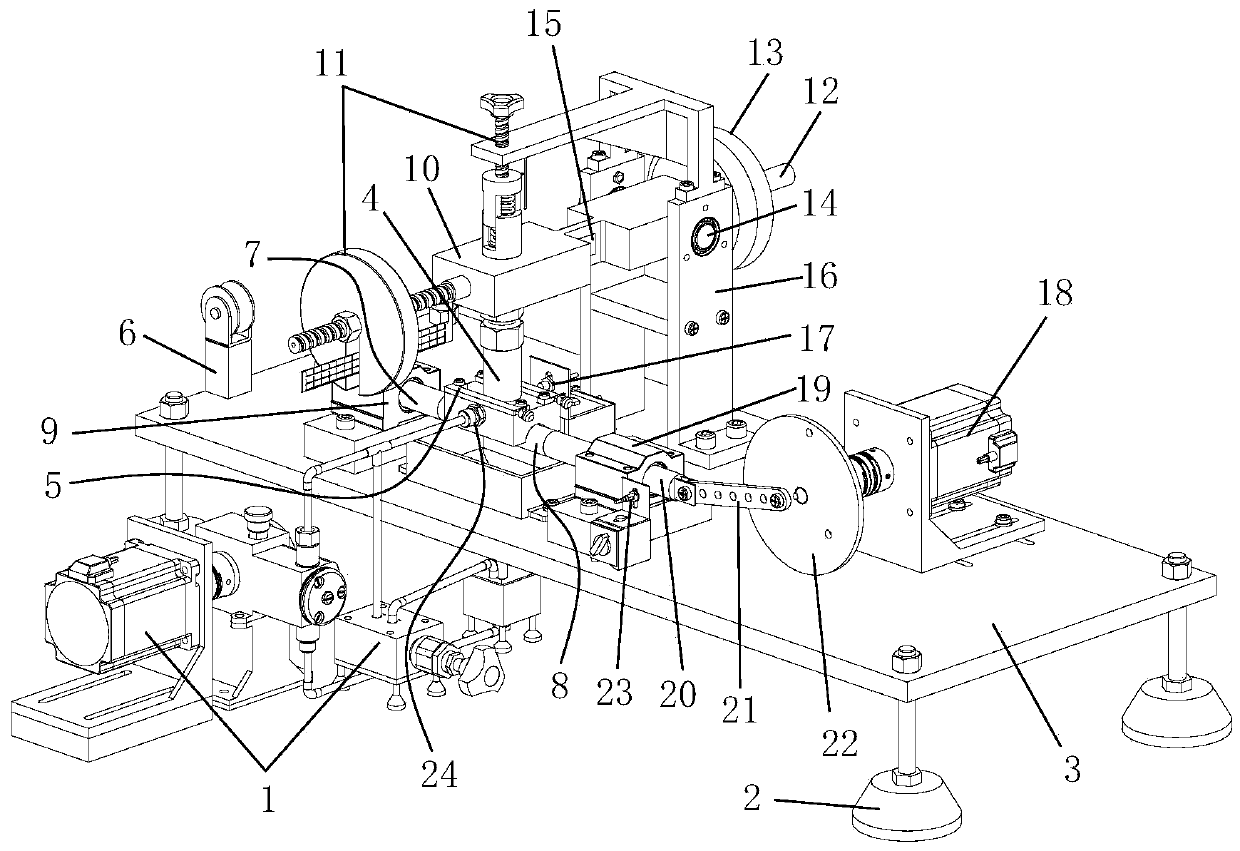

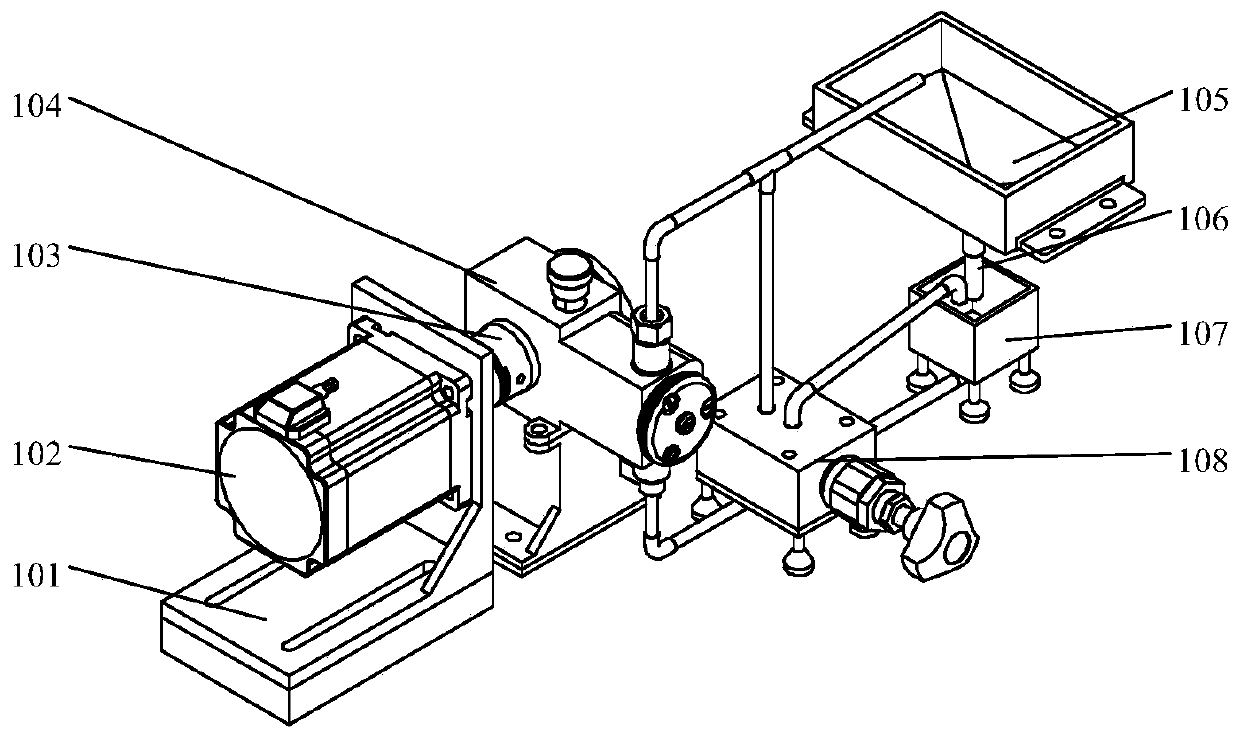

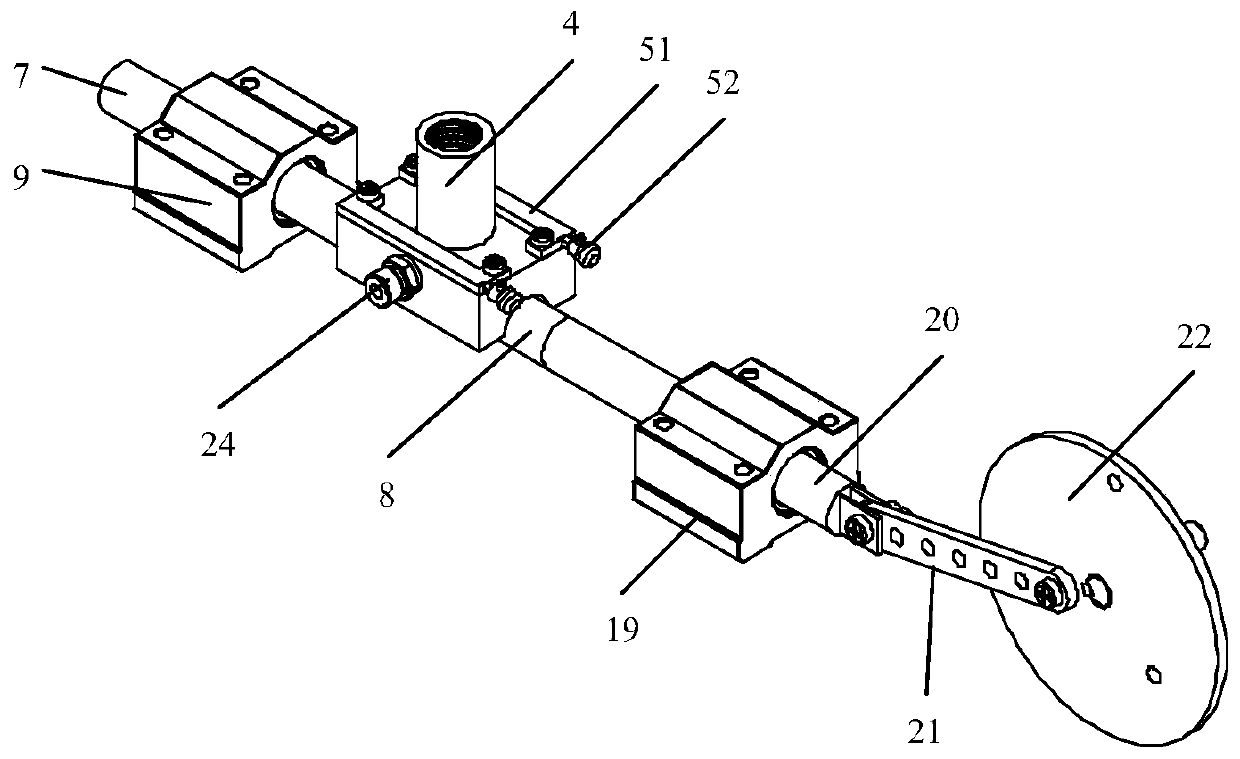

[0035] see Figure 1-12 , in the present invention, a reciprocating friction and wear testing machine with its own lubrication and composite force loading system includes a lubrication system 1, a base foot 2, a base 3, an upper test piece 4, a heating device 5, a fixed pulley 6, and a guide rod Ⅰ7, lower test piece 8, linear bearing Ⅰ9, flexible beam 10, compound force loading system 11, balance weight rod 12, balance weight 13, rotating shaft 14, strain gauge 15, L-shaped bracket 16, temperature sensor 17, speed control Motor 18, linear bearing II 19, guide rod II 20, connecting rod 21, crank di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com