Quick in-situ preparation method of noctiluca-shaped graphene wrapped silicon carbide microsphere

A technology of olefin-coated silicon carbide and noctiluca, applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems affecting the performance of graphene lubricating oil additives and their industrial applications, scratches on the surface of friction pairs, and difficulty in dispersion and stability. , to achieve the effect of solving difficult to apply to lubricating oil additives, low cost, no impurity pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Weigh 500 mg of nano-silicon carbide powder (purity 99.9%, particle size less than 0.04-0.2 μm) into a beaker, add 50 mL of absolute ethanol, and ultrasonically disperse until there is no precipitation at the bottom of the beaker to form a uniform suspension;

[0034] (2) The suspension prepared in the above step (1) was irradiated with the argon-fluorine laser beam (193 nm) focused by a mirror and a convex lens, and the laser energy density was 0.8 J pulse -1 cm -1 , the frequency is 2 Hz, and the irradiation time is 20 min. During laser beam irradiation, the magnetic stirrer was set at 300 rpm -1 Stir the suspension at a constant speed;

[0035] (3) After irradiation, the suspension was centrifuged, then washed three times with a mixed acid solution (5 wt% hydrofluoric acid and 5 wt% hydrogen peroxide) and deionized water, and dried to obtain the product.

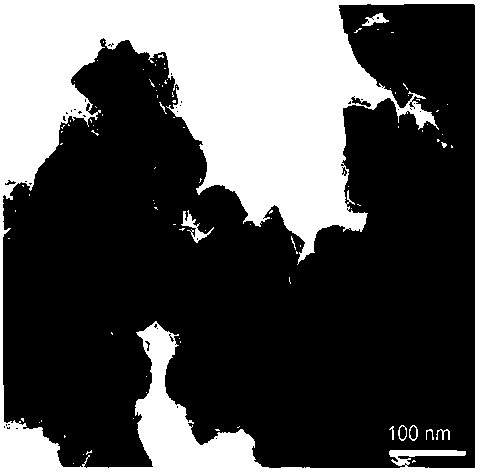

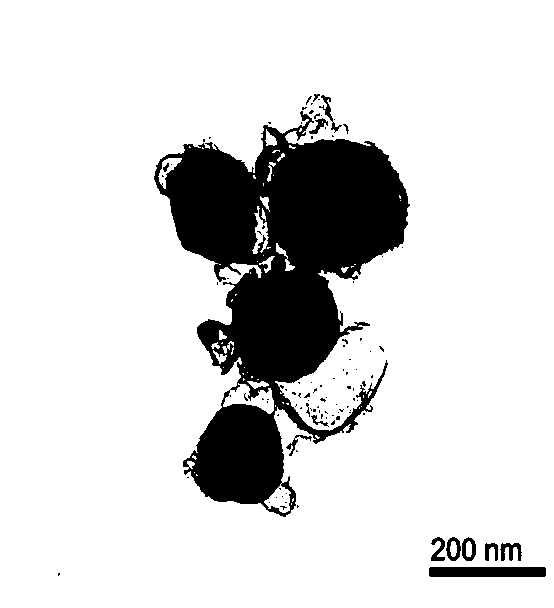

[0036] figure 1It is a transmission electron microscope picture of the original silicon carbide powder ...

Embodiment 2

[0039] (1) Weigh 250 mg of ultrafine silicon carbide powder (purity 99%, particle size 0.5-0.7 μm) into a beaker, add 50 mL of absolute ethanol, and ultrasonically disperse until there is no precipitation at the bottom of the beaker to form a uniform suspension;

[0040] (2) Irradiate the suspension prepared in the above step (1) with the krypton-fluorine laser beam (248 nm) focused by the mirror and the convex lens, and the laser energy density is 1.0 J pulse -1 cm -1 , the frequency is 10 Hz, and the irradiation time is 10 min. During laser beam irradiation, a magnetic stirrer was used at 700 rpm -1 Stir the suspension at a constant speed;

[0041] (3) After irradiation, the suspension was centrifuged, then washed three times with a mixed acid solution (10 wt% hydrofluoric acid and 10 wt% hydrogen peroxide) and deionized water, and dried to obtain the product. The appearance of the obtained product is similar to that of Example 1, and the particle size is 0.3-0.5 μm.

Embodiment 3

[0043] (1) Weigh 5 mg of nano-silicon carbide powder (purity 99.9%, particle size less than 0.04-0.2 μm) into a beaker, add 50 mL of absolute ethanol, and ultrasonically disperse until there is no precipitation at the bottom of the beaker to form a uniform suspension;

[0044] (2) The suspension prepared in the above step (1) was irradiated with the xenon-chlorine laser beam (308 nm) focused by the mirror and the convex lens, and the laser energy density was 1.2 J pulse -1 cm -1 , the frequency is 15 Hz, and the irradiation time is 5 min. During laser beam irradiation, a magnetic stirrer was used at 1000 r min -1 Stir the suspension at a constant speed;

[0045] (3) After irradiation, the suspension was centrifuged, washed three times with mixed acid solution (5 wt% hydrofluoric acid and 10 wt% hydrogen peroxide) and deionized water, and dried to obtain the product. The appearance of the obtained product is similar to that of Example 1, and the particle size is 0.1-0.2 μm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com