Variable-rigidity mechanism based on geometrical features

A technology with geometric characteristics and variable stiffness, applied in the field of robotics, can solve the problems of complex structure, poor linearity, and low position accuracy of variable stiffness mechanisms, and achieve the effects of good linearity, improved control accuracy, and convenient layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

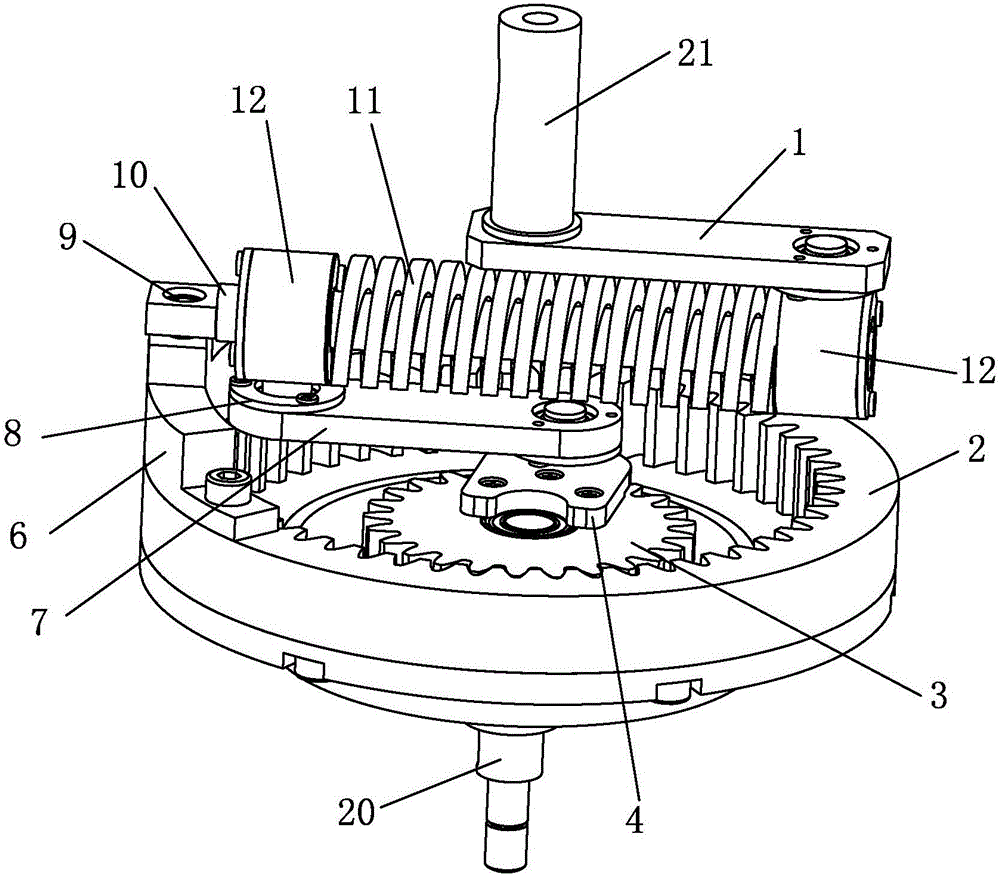

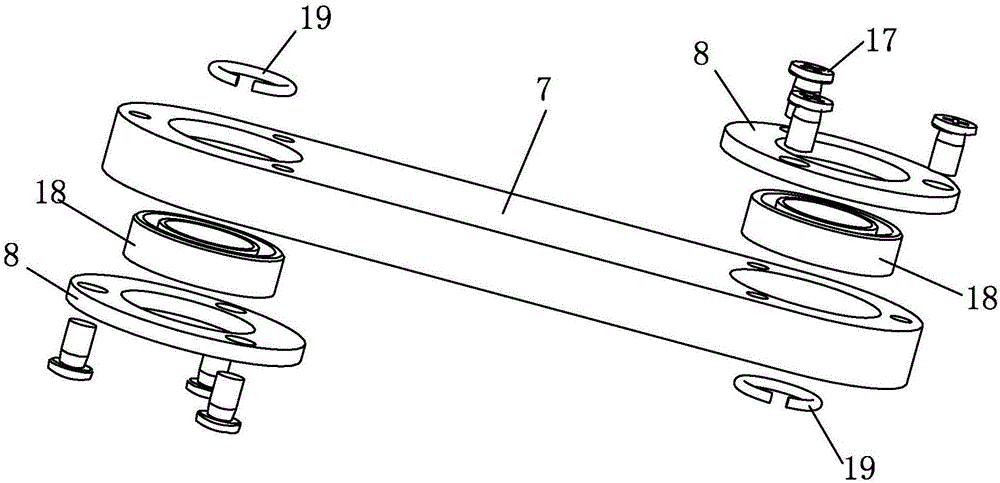

[0019] combine Figure 1-Figure 3 Explain that a variable stiffness mechanism based on geometric characteristics in this embodiment includes an output rod 1, a rigidly adjustable ring gear 2, a fulcrum gear 3, a fulcrum frame 4, a fulcrum rod 7, an intermediate rod 10, a spring 11, a bushing 13 and two sliders 12;

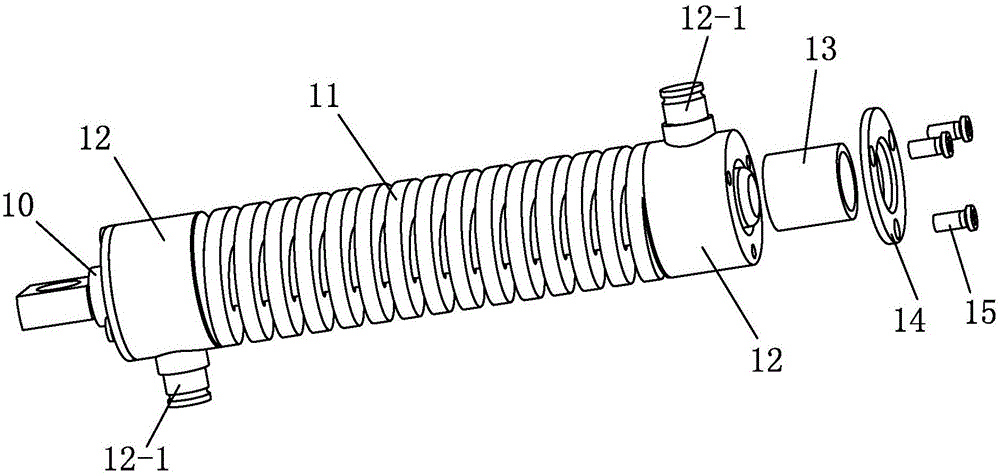

[0020] The two ends of described intermediate bar 10 are respectively equipped with a described slide block 12, and the described intermediate bar 10 that is positioned between two described slide blocks 12 is provided with spring 11, and is set between slide block 12 and intermediate bar 10. There is a shaft sleeve 13, and the shaft sleeve 13 is axially positioned by the bearing end cover 14 installed on the slider 12;

[0021] The upper end of the rigidly adjustable main shaft 20 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com