Machine tool for ring mold gun drill

A special machine tool and gun drilling technology, which is applied to the parts of the boring machine/drilling machine, the measurement of positioning in the boring machine/drilling machine, boring/drilling, etc., can solve the problems of laborious, time-consuming, and difficult processing, and achieve the stability of the machine tool and good precision, long trouble-free running time, and the effect of reducing labor and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

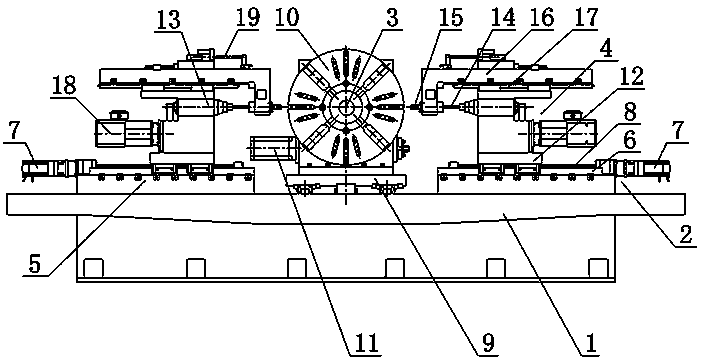

[0020] Such as figure 1 As shown, the special machine tool for ring die gun drilling includes machine bed 1, feed slide table 2, CNC turntable 3, gun drill drilling power mechanism 4, high-pressure cutting oil system and electric control system, two sets of feed slide table 2 are respectively horizontally and fixedly installed on both sides above the machine bed 1, the CNC turntable 3 is installed at the middle position above the machine bed 1, and the two gun drill drilling power mechanisms 4 are respectively slidably installed on two sets of feed slides 2 ; The feed slide 2 includes a slide base 5, a slide rail 6, a servo motor 7 and a ball screw 8, the slide base 5 is fixed on the machine bed 1, the slide rail 6 is installed on the slide base 5, and the slide base 5, a ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com