Method for processing slant oil hole in middle-speed machine crankshaft

A technology of oblique oil holes and crankshafts, which is applied in metal processing equipment, manufacturing tools, boring/drilling, etc., and can solve the problems that the drill bit is easy to break and cannot be drilled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

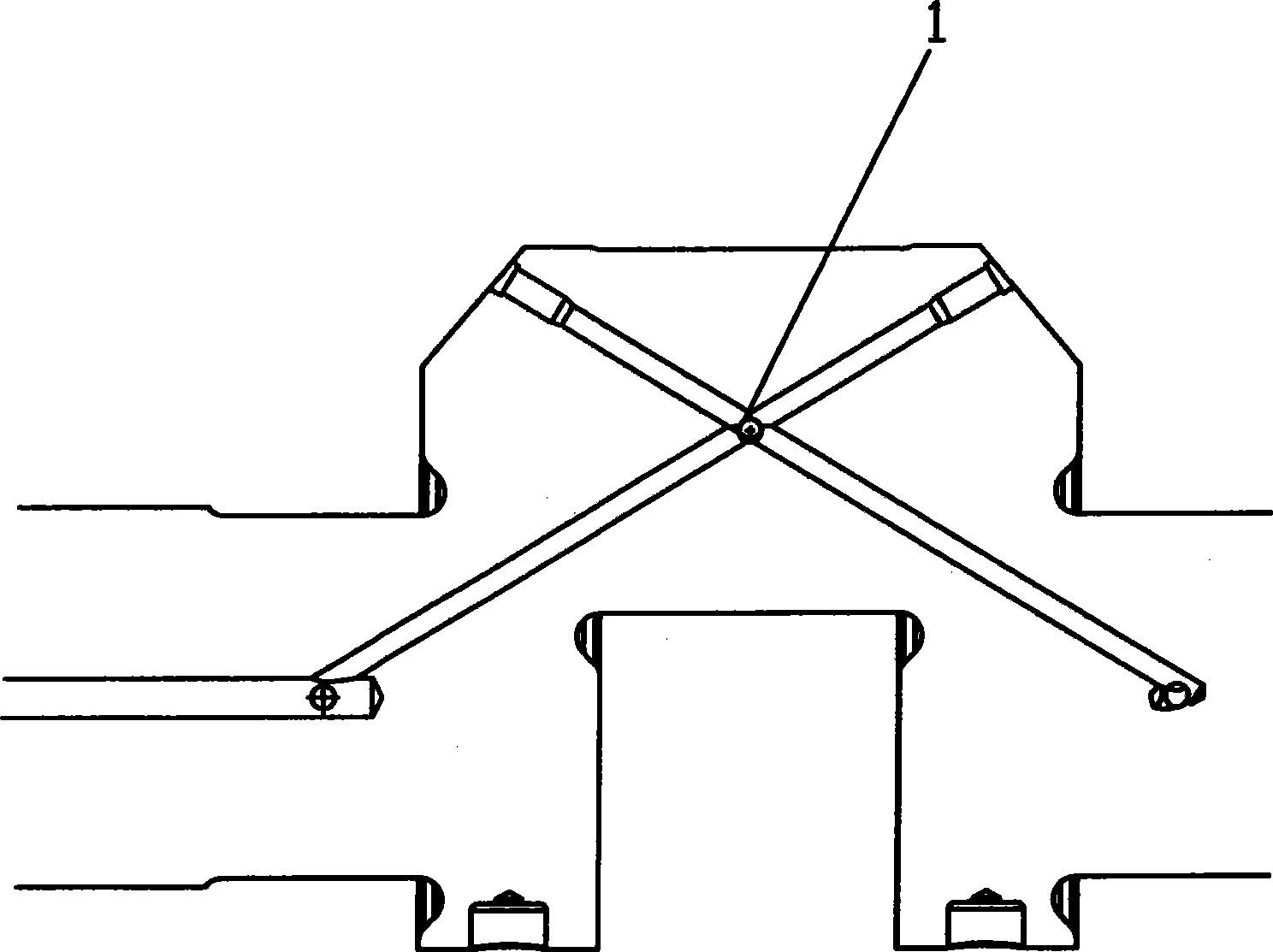

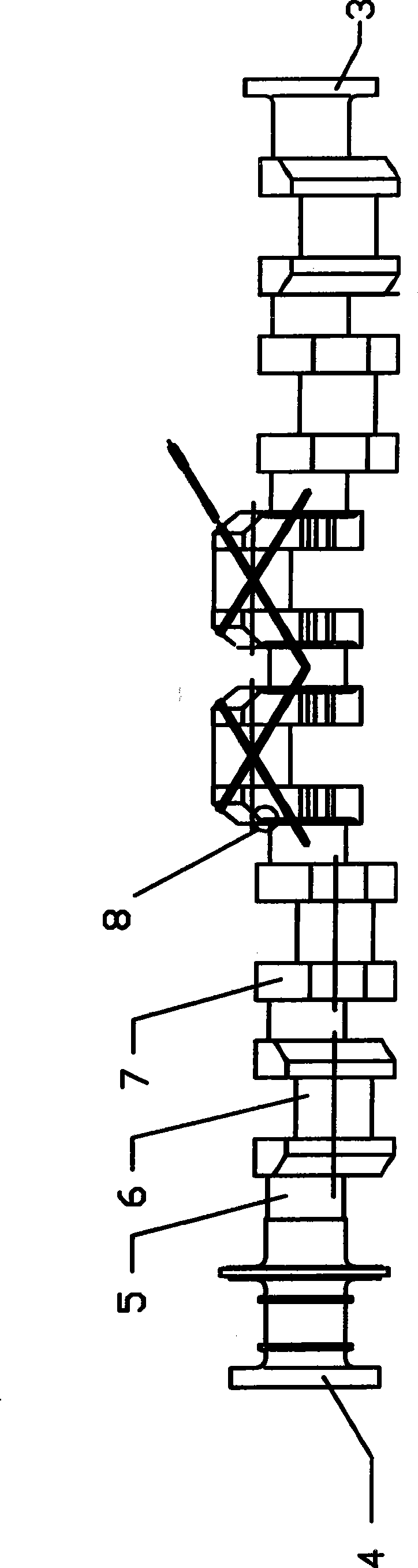

[0012] refer to image 3 , Figure 4 , The crankshaft of the medium-speed machine mainly consists of free end 3, thrust end 4, main journal 5, turning neck 6, turning arm 7 and other parts. Wherein there are load relief grooves 8, φ20 crossing oblique oil holes 1, and balance block surfaces 9.

[0013] When processing the crankshaft of a medium-speed machine, the crankshaft blank of the medium-speed machine is formed by TR pier forging in one time according to the traditional method, and then the main journal, turning neck, load relief groove, output end, and free end flange are milled, and the shape of the balance block and the crank arm is milled. , Drilling and machining of evenly distributed holes and screw holes on the end face of the flange, grinding the main journal and turning neck, and finishing.

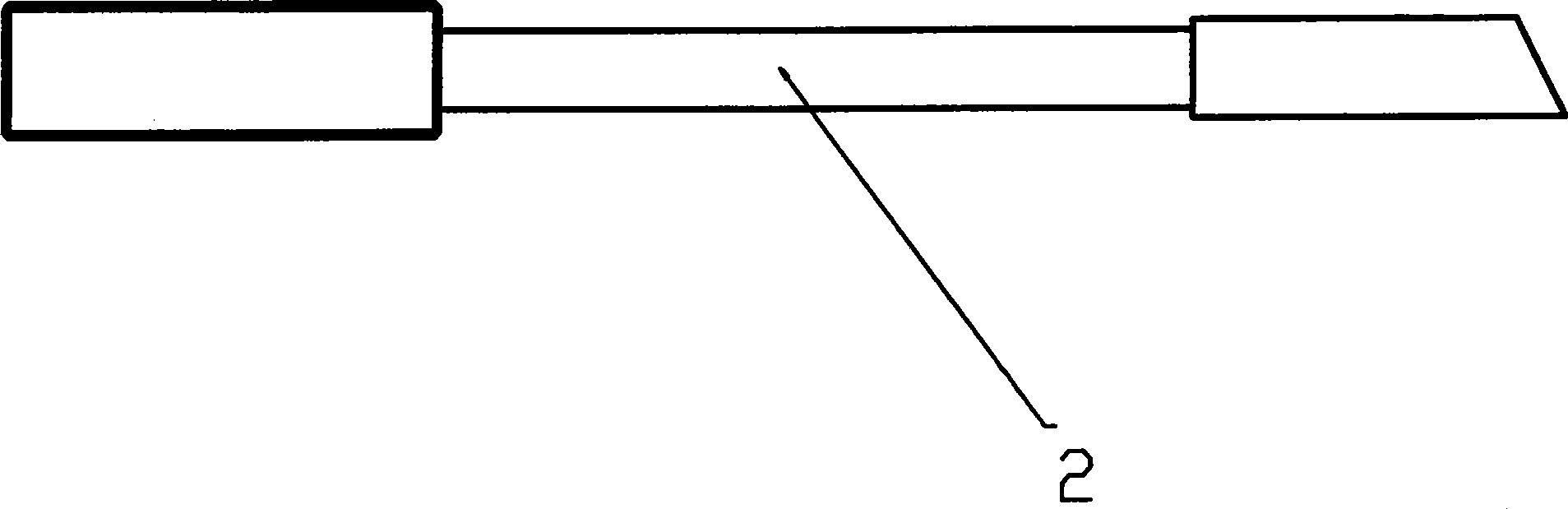

[0014] Machining by gun drilling figure 1 The shown 700mm long, φ206PC crankshaft oblique oil hole can be processed in 30 minutes, and the size and roughness can meet th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com