Guide mechanism of gun drill of vertical numerical control drilling machine

A technology of guiding mechanism and machine tool, applied in drilling/drilling equipment, components of boring machine/drilling machine, positioning measurement in boring machine/drilling machine, etc. , to achieve the effect of good comprehensive mechanical performance, improved rigidity and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the following, the present invention will be further described in conjunction with the drawings and specific implementations. It should be noted that, provided that there is no conflict, the following embodiments or technical features can be combined to form new embodiments. .

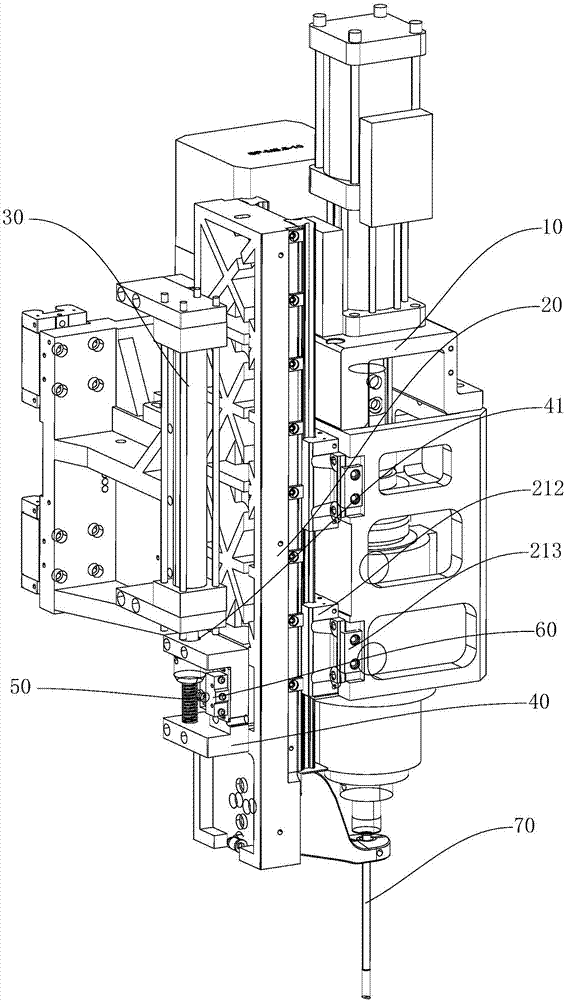

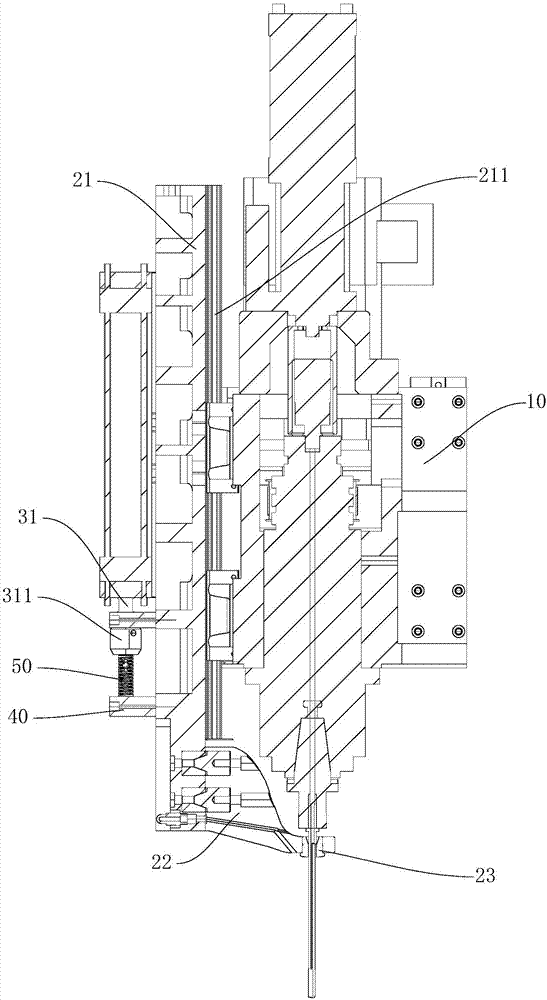

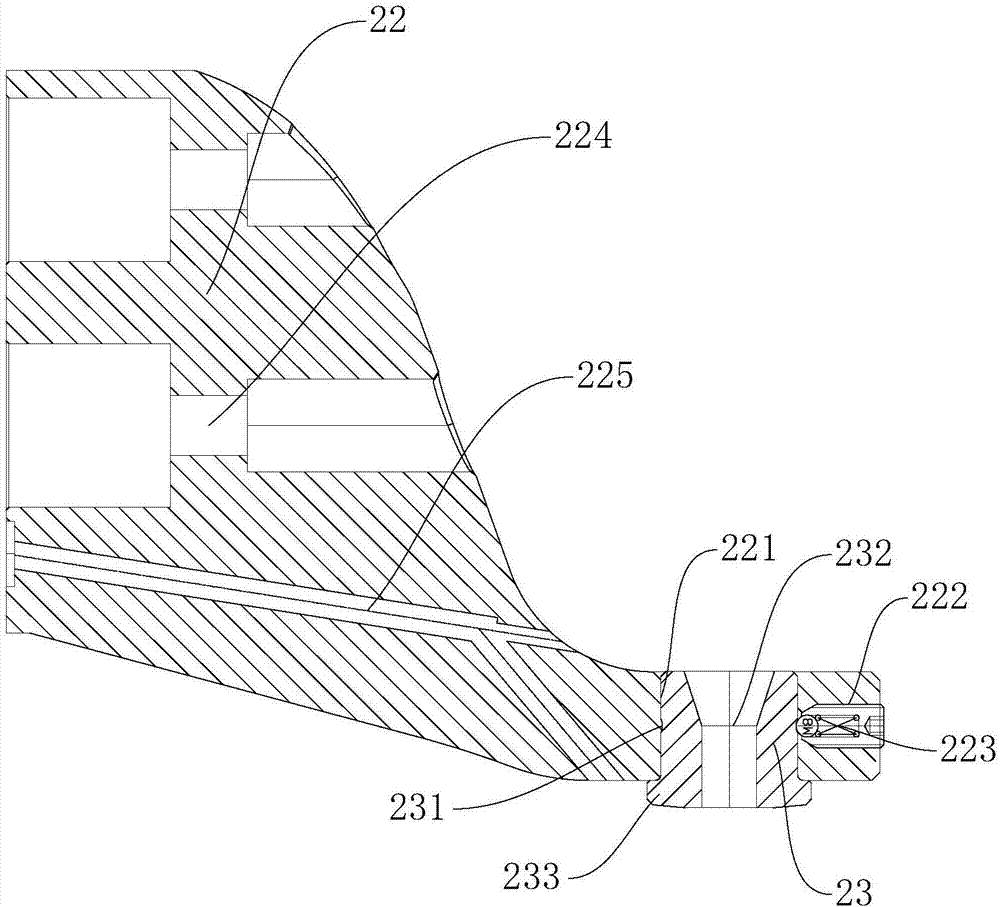

[0025] Such as Figure 1-3 As shown, the guiding mechanism of the embodiment of the present invention includes a main shaft frame 10, a guide sleeve assembly 20 slidably connected to the main shaft frame 10, and a driving device 30 for driving the guide sleeve assembly 20 to slide along the main frame 10, and the driving device 30 is fixedly connected On the spindle frame 10, the guide sleeve assembly 20 includes a sliding seat 21, a guide sleeve bracket 22 fixed to the bottom of the sliding seat 21, and a metal guide sleeve 23 fixed on the guide sleeve bracket 22. The sliding seat 21 is close to a part of the spindle frame 10. At least two guide rails 211 are provided on the side. Each guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com