Power head structure of deep-hole drilling machine

A technology of deep hole drilling machine and power head, which is applied to the parts of boring machine/drilling machine, boring/drilling, drilling/drilling equipment, etc. It can solve the problems of poor precision, large structure size and low speed, and achieve structural Small size, wide speed range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific drawings and embodiments.

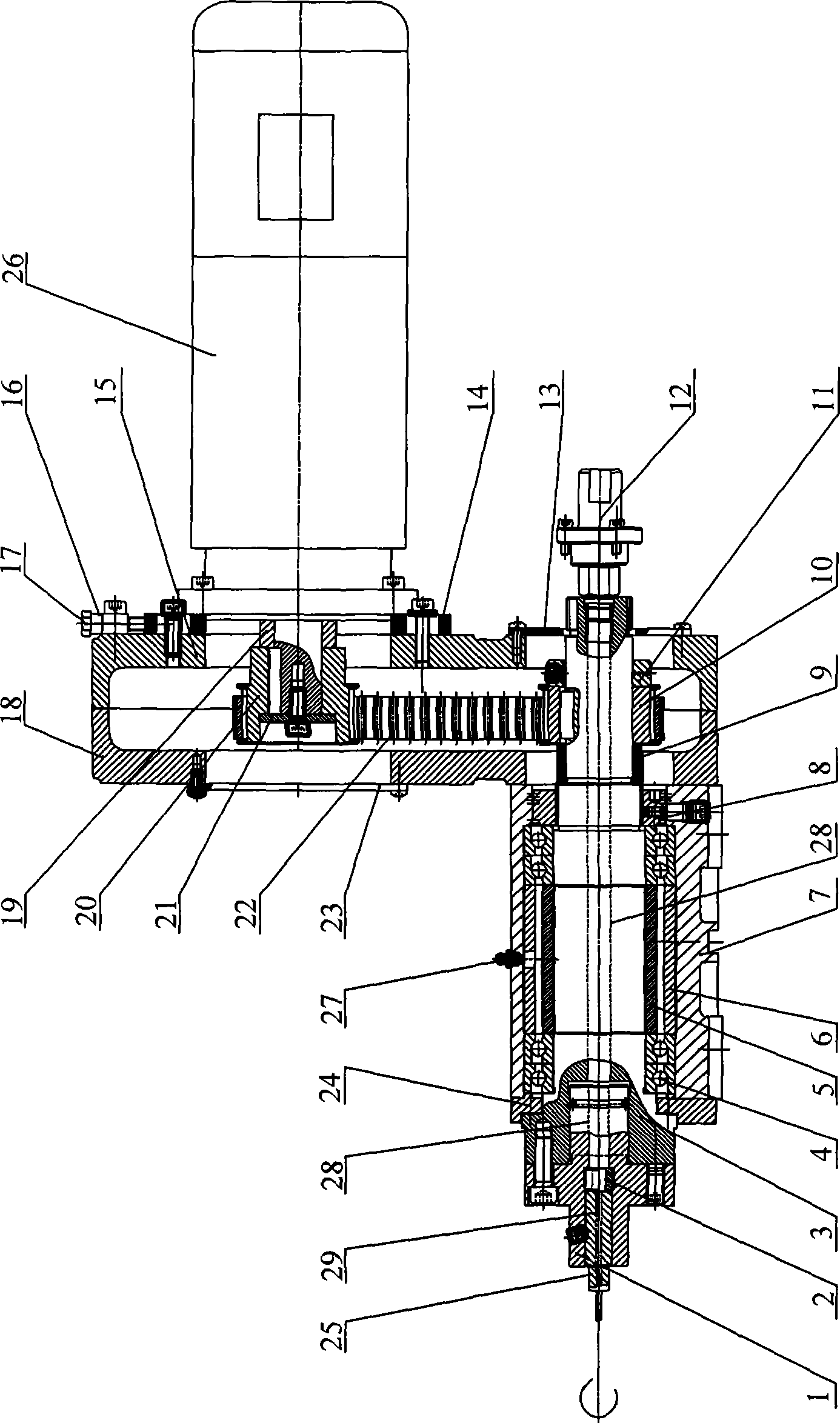

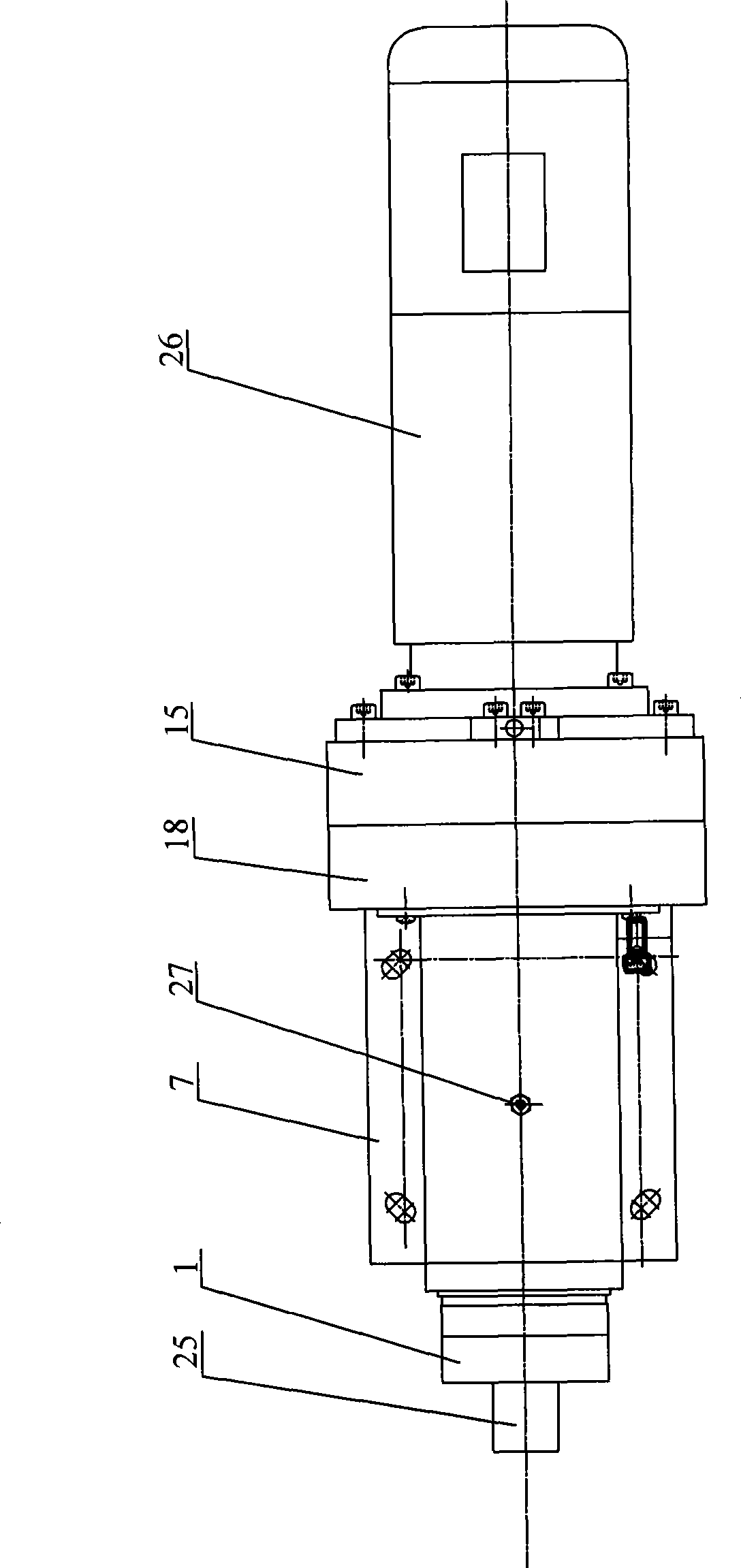

[0010] As shown in the figure: the present invention mainly consists of arbor chuck 1, axial positioning sleeve 2, main shaft 3, bearing 4, inner spacer 5, outer spacer 6, main shaft seat 7, lock nut 8, spacer 9, Synchronous pulley 10, locking retaining ring 11, rotary joint 12, cover plate 13, middle plate 14, rear box body 15, tension seat 16, tension screw 17, front box body 18, spacer sleeve 19, driving wheel 20 , pressing plate 21, synchronous driving belt 22, front cover plate 23, flange 24, gun drill 25, main shaft motor 26, oil nozzle 27, axle hole 28 and parts such as coolant ejection hole 29 constitute.

[0011] The power head structure of the deep hole drilling machine of the present invention comprises a main shaft motor 26, a front box body 18, a rear box body 15, a main shaft 3 and a main shaft seat 7, and the front box body 18 and the rear box bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com