Positioning and supporting auxiliary tool for precise drilling in aircraft

A technology of positioning support and auxiliary tooling, which is applied in the direction of drilling/drilling equipment, worktables, manufacturing tools, etc., can solve problems such as unguaranteed, economic loss, and increased drilling failure, so as to improve accuracy, improve efficiency, and improve convenience effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

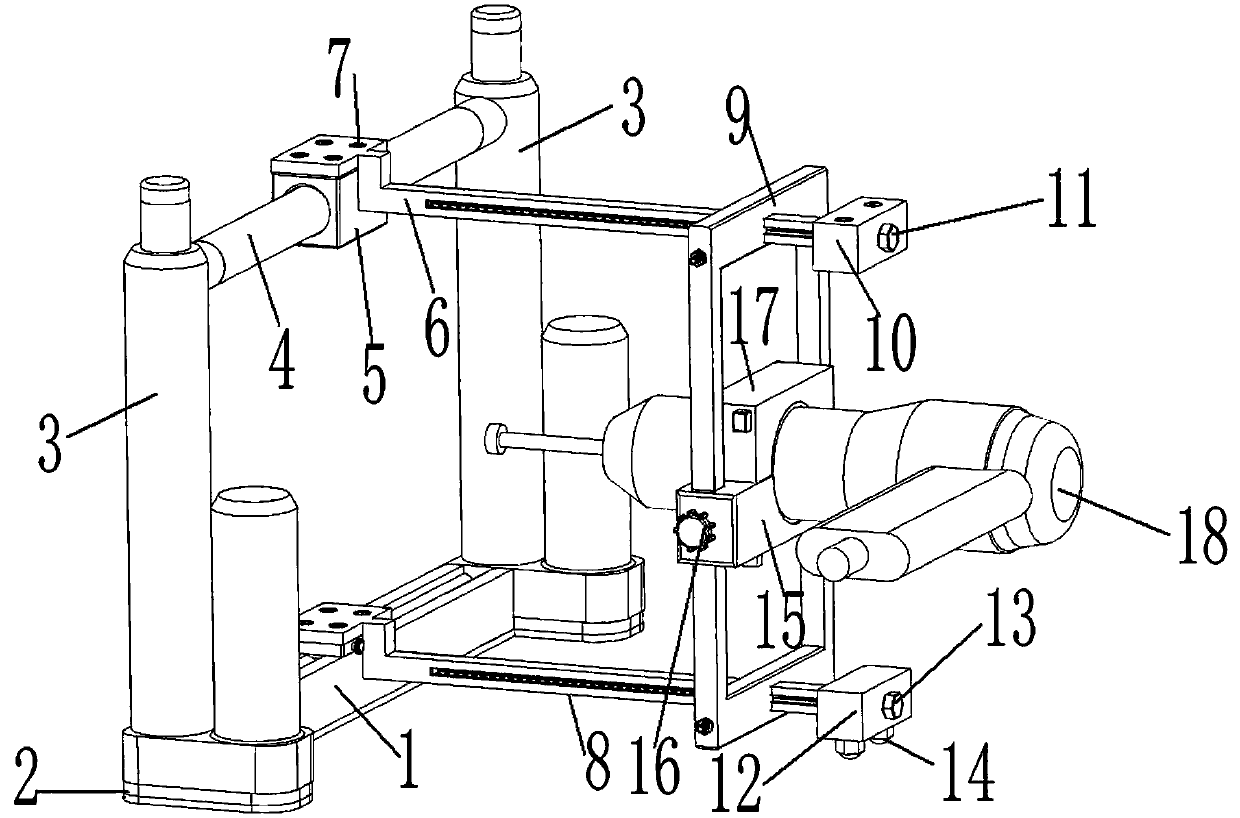

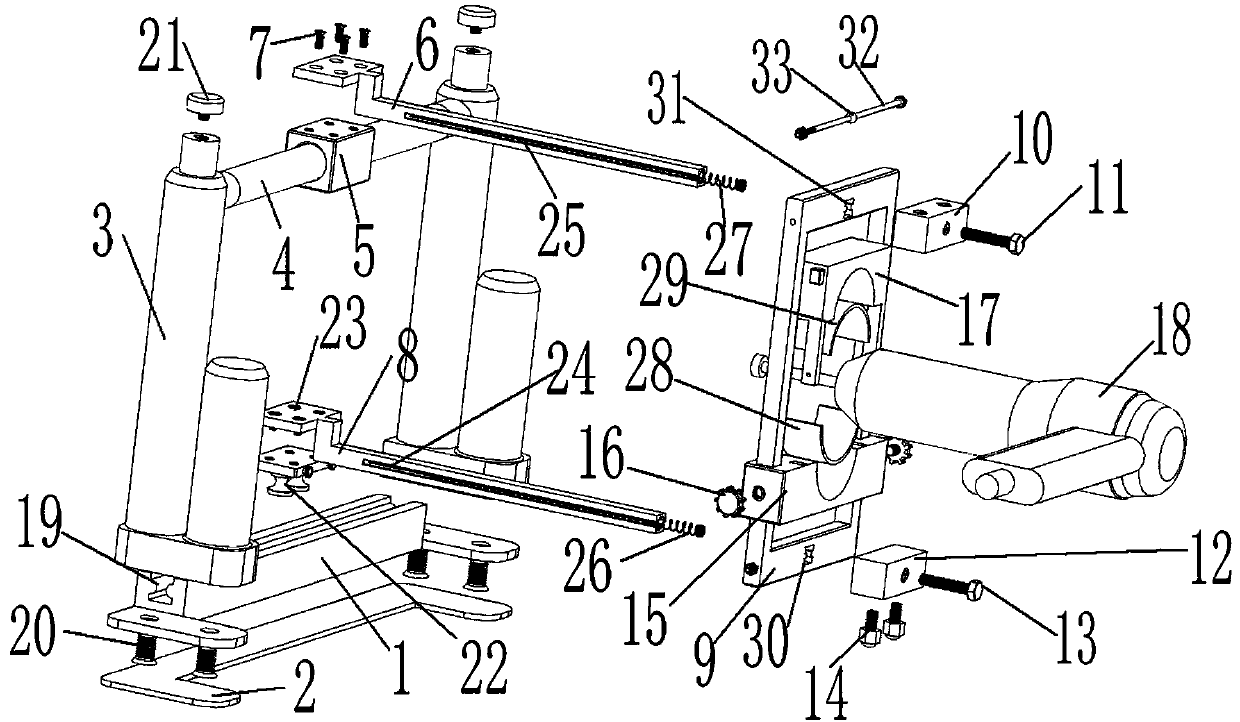

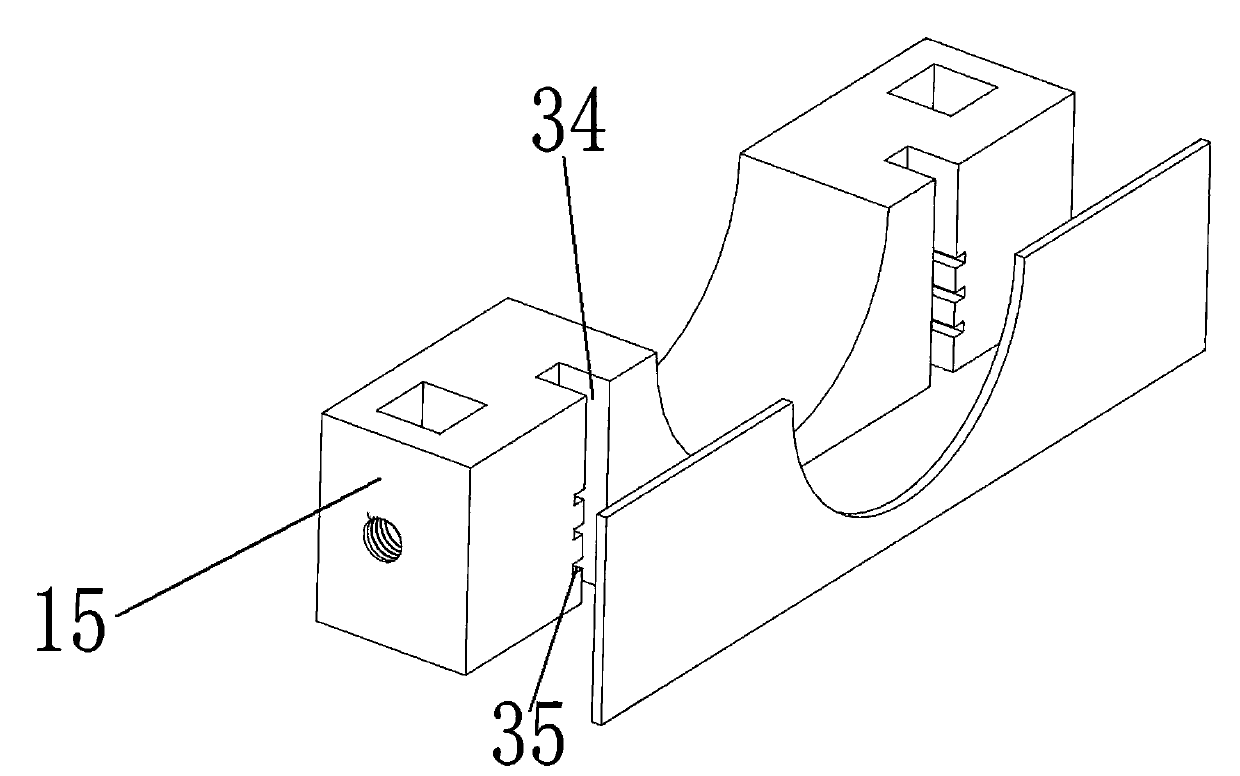

[0028] Attached below figure 1 to attach Figure 4 The present invention will be further described.

[0029] A positioning support auxiliary tool for precise drilling on an aircraft, comprising: a slide rail 1, which is horizontally arranged along the left and right directions, and a guide rail groove I 19 is horizontally arranged inside the slide rail 1; a slider 22, which is slid and installed on the Inside the guide rail groove I 19; two electric telescopic rods 3 are vertically fixed to the left and right ends of the slide rail 1 through screws II 20 respectively; the connecting shaft 4 is set horizontally, and its two ends are connected with the electric telescopic rod 3 on the same side respectively. The top is connected, the connecting shaft 4 is parallel to the slide rail 1, and the linear bearing 5 is slidingly installed on the connecting shaft 4 along the left and right directions; the longitudinal slide rail I 6 is set horizontally along the front and rear directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com