Gun drill

A pistol drill and drill bit technology, applied in the field of pistol drills, can solve problems such as injury to operator safety, long metal chips, and annealing of drill bits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

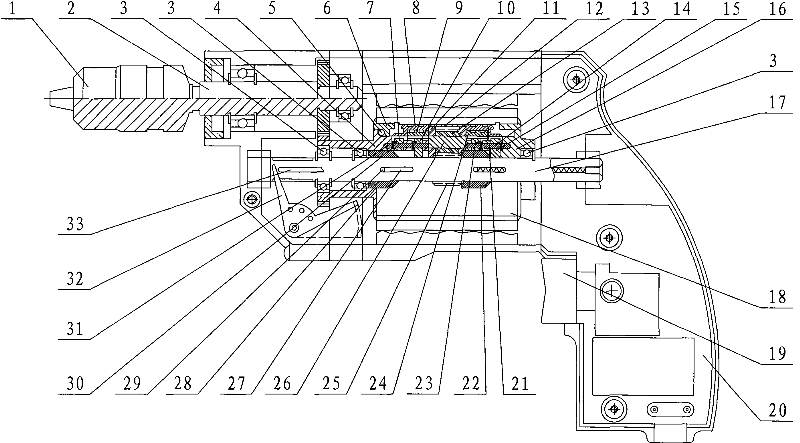

[0014] As can be seen from the structural sectional view of the gun drill of the present invention shown in the accompanying drawings, the gun drill includes a housing 20, a switch 19, a drill bit 1, a drill shaft 2, a motor with a rotor and a stator, and the rotor of the motor includes a rotor housing Body 18 and main shaft 17 are also provided with an output device capable of adjusting the rotating speed of the rotor.

[0015] The output device capable of adjusting the rotor speed includes a speed regulating mechanism, a planetary gear mechanism and a clutch mechanism. Wherein, the speed regulating mechanism is installed in the main shaft 17, the planetary gear mechanism is arranged in the middle of the rotor housing 18, and the clutch mechanism is arranged on the front and rear sides of the planetary gear mechanism.

[0016] Speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com